Middle management key to unlocking AI advantage in manufacturing

In 2024, the government has also issued Decree 182 on the establishment, management, and utilisation of the Investment Support Fund. The Investment Support Fund will offer up to 50 per cent of initial investment costs for semiconductors and AI investors with research and development projects.

These bold moves have swiftly and powerfully shifted the tone around AI towards big investment, calculated risk taking, and the drive to win with the best AI development and real-life outcomes for business and society. It should provide another catalyst for manufacturing leaders to think more about their own AI investment strategy, even in the face of tough times, fluctuating demand, and geopolitics.

|

| Christanto Suryadarma, sales vice president for Southeast Asia, South Korea, and Channel APJeC at Zebra Technologies |

Manufacturers’ data conundrum

Minister of Information and Communications Nguyen Manh Hung emphasised that AI is the core technology of the Fourth Industrial Revolution, which is true. However, the use cases and compliance requirements for pharmaceuticals, automotives, and food are high and require more advanced AI such as deep learning and 3D scan software to handle them.

These AI ambitions are naturally tied to the need for data – lots of high value, good quality data, which we see in manufacturing across many processes. To unlock AI’s full potential, industries will need to collaborate and federate their data in secure, structured ways. Creating safe environments for data sharing is becoming a priority, as AI thrives not only on competition but also on cooperation. Globally, there is a push for accessible, privacy-preserving data infrastructures. For example, initiatives like publicly accessible high-value datasets and proposals for national data libraries are being explored to support research, innovation, and responsible AI development.

This reminds us of the challenge manufacturers face within their companies. A recent piece of research by Zebra Technologies found that among machine vision leaders in the automotive industry, almost 20 per cent in Germany and the UK say their AI machine vision could be working better or doing more. The same concern applies in Vietnam, where the success of AI-driven solutions depends heavily on the quality and availability of data. For AI solutions to achieve their potential, the question of data must be addressed.

|

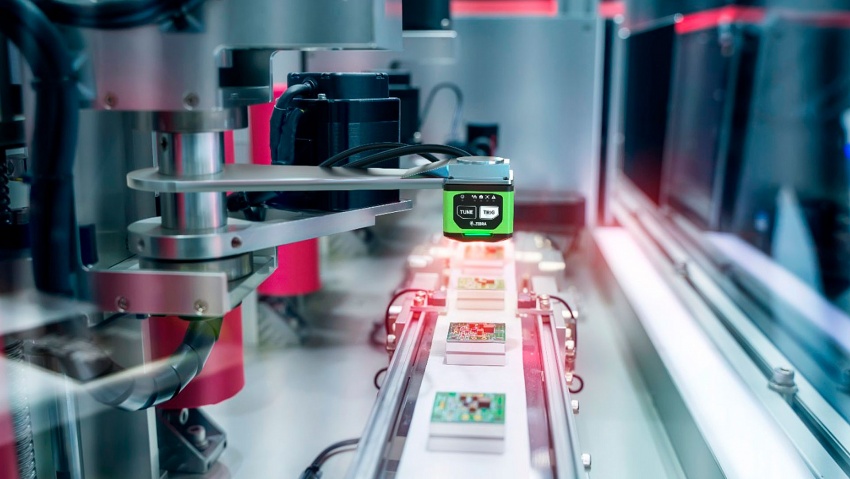

| Zebra Machine Vision solution for the manufacturing industry |

The volume of data being created at the edge of business can be turned into value. That could be data for training and testing AI models, or acting as feedback to refine processes around manufacturing and inspection. Once data and AI are integrated, the path to process automation – with smart cameras, sensors, and vision-guided robotics – becomes a reality, allowing leaders to reallocate valuable connected frontline workers to growth-focused areas.

However, manufacturing sites and regions can operate in silos, with little to no sharing of data, even for identical or similar workflows. Experience and time available can vary between teams and sites, which can make achieving data quality more challenging, compounded by struggling to hire the right talent with the right skills and experience.

Data needs to be stored, annotated, and used for training models in a consistent way, with other data sets needed for model testing. It makes no sense for company data to remain siloed, to the detriment of better training for AI.

How are manufacturers to achieve this if they cannot leverage all the data available to them across sites, countries, and regions? How much growth potential and workforce productivity are being lost? The hesitancy around the cloud due to privacy, security, and intellectual property needs to be overcome. A cloud-based solution would allow users to securely upload, label, and annotate data from multiple manufacturing locations across a site, country, and region and deliver scalability and accessibility of computing power.

The options for getting AI solutions working better and doing more are available, whatever the use case might be. There are software, cameras, and sensors for use cases including electric battery and semiconductor inspection, fresh food sortation, packaging compliance and quality, serial number and character reading, and defect detection for automotive parts and finished items.

However, AI working better or doing more needs to be measured with appropriate timelines, return on investment metrics, and quality data. Alongside data management transformation, intelligent automation and greater asset visibility require appropriate implementations, workforce training and operational adjustments which take time. Other AI solutions take a low/no code approach, and come ready out of the box, delivering a faster return on investment.

In praise of middle management

Who can shift the tone and lead the drive to win when it comes to AI within manufacturing companies? Recent research by McKinsey highlighted that many millennials aged 35 to 44 are managers and team leaders in their companies, i.e. middle managers. They are on the frontline of business, walking the factory floor, and acting as the bridge between the connected frontline workers and senior leadership. These middle managers report having the most experience and enthusiasm about AI, with 62 per cent of employees between the ages of 35 and 44 reporting high levels of expertise with AI.

|

| It’s time to unlock AI’s full potential in manufacturing |

Separate research found that only 30 per cent of business leaders (CEOs, presidents, other C-suite executives, senior vice presidents, and executive vice presidents) increase resourcing for growth initiatives in core, adjacent, or new businesses during periods of volatility. Only 29 per cent said they invest 30 per cent or more of their time on long-term growth initiatives.

Middle managers are a key talent pool senior leaders should leverage to answer questions like how AI, such as deep learning machine vision, can help accelerate through a challenging market and drive long-term growth, elevate productivity, automate processes, and improve quality.

Despite the initial reaction to contract and pause projects in the face of hard times, now might be the right moment to rethink the role middle management plays when it comes to prioritising growth and acting boldly with AI and machine vision. By empowering connected frontline workers and ensuring asset visibility, middle managers can drive meaningful change and unlock AI’s full potential in manufacturing.

| There’s no more time for hype when it comes to AI Christanto Suryadarma, sales vice president for Southeast Asia, South Korea and Channel APJeC, Zebra Technologies, speaks about AI development. |

| Santan, Soft Space take inflight retail to new heights Santan, the inflight catering and food and beverage subsidiary of Capital A, in collaboration with Soft Space Sdn. Bhd. (Soft Space), the world's leading fintech-as-a-service (FaaS) provider, on January 9 announced a major upgrade to its inflight retail solution, Fasspos. |

| Zebra Technologies hosts summit in Danang Zebra Technologies Corporation, a mobile computing company specialising in smart data capture, hosted its 2025 Regional Partner Summit in Danang March 5. |

| Zebra Technologies announces new strategy for 2025 in Vietnam Zebra Technologies Corporation, a global leader in digitising and automating frontline workers, is looking to expand in Vietnam by anchoring on an extensive network of partners, continued investment, and a comprehensive portfolio of solutions. |

(*) Christanto Suryadarma, sales vice president for Southeast Asia, South Korea, and Channel APJeC at Zebra Technologies

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Themes: Digital Transformation

- Dassault Systèmes and Nvidia to build platform powering virtual twins

- Sci-tech sector sees January revenue growth of 23 per cent

- Advanced semiconductor testing and packaging plant to become operational in 2027

- BIM and ISO 19650 seen as key to improving project efficiency

- Viettel starts construction of semiconductor chip production plant

Related Contents

Latest News

More News

- Vietnam forest protection initiative launched (February 07, 2026 | 09:00)

- China buys $1.5bn of Vietnam farm produce in early 2026 (February 06, 2026 | 20:00)

- Vietnam-South Africa strategic partnership boosts business links (February 06, 2026 | 13:28)

- Mondelez Kinh Do renews the spirit of togetherness (February 06, 2026 | 09:35)

- Seafood exports rise in January (February 05, 2026 | 17:31)

- Accelerating digitalisation of air traffic services in Vietnam (February 05, 2026 | 17:30)

- Ekko raises $4.2 million to improve employee retention and financial wellbeing (February 05, 2026 | 17:28)

- Dassault Systèmes and Nvidia to build platform powering virtual twins (February 04, 2026 | 08:00)

- The PAN Group acquires $56 million in after-tax profit in 2025 (February 03, 2026 | 13:06)

- Young entrepreneurs community to accelerate admin reform (February 03, 2026 | 13:04)

Tag:

Tag:

Mobile Version

Mobile Version