High-tech adoption for TH true MILK

At the Vietnam Socioeconomic Achievements Exhibition in August in Hanoi, TH Group showcased what it described as a “digital miracle” to visitors: an advanced traceability technology that allows comprehensive tracking of every stage in the 12-step production process of TH true MILK - from pasture, farms, and factory all the way to consumer’s dining tables.

|

| High-tech adoption for TH true MILK |

This innovation mirrors the agricultural digitalisation vision persistently pursued by the company, in which modern agricultural development is inseparable from data, technology, and AI.

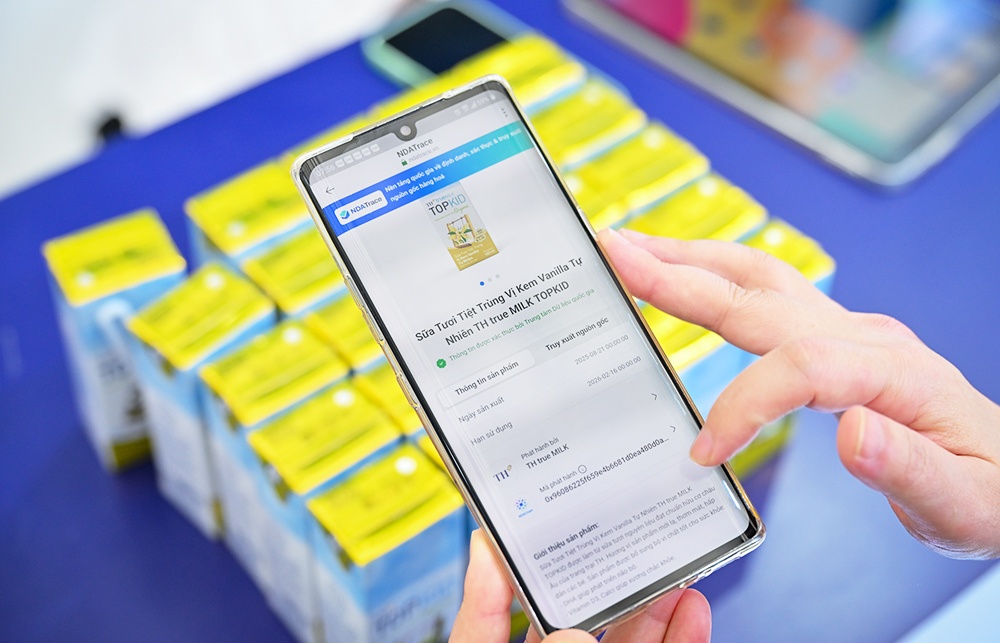

With this major step, TH has become the first dairy enterprise in Vietnam to provide traceability data on the National Data Association’s (NDA) Trace platform, a blockchain-based, nationally integrated system developed by Vietnamese experts, featuring decentralised identity technology.

The technology allows users to control their digital identities by managing their own personal data, which is secured using cryptography and distributed ledger technology like blockchain.

Each batch of TH true MILK is provided with a unique digital ID, enabling end-to-end tracking from raw material input, production, quality control, packaging, and transportation to final distribution.

Every action in the supply chain is recorded, verified, and protected against tampering or forgery. This technology complies with international GS1 standards and is compatible with EBSI Trace 4EU - the European Union’s global traceability system - providing comprehensive assistance for the enterprise’s cross-border supply chain connection.

On every TH milk carton, the QR code works as a digital certificate of trust. “When scanning the code, consumers can access full details about the milk’s origin, production process, ingredients, nutritional content, storage instructions, expiry date, and packaging specifications,” said Nguyen Xuan Khoa, chief information officer at TH Group. “They can even discover what, when, and how the cows were fed and treated, and how they were milked. Everything is transparent and verifiable.”

TH taking the lead in using data and technology for product traceability has marked a defining moment in its 15-year journey to bring greater transparency to the Vietnamese dairy market in a bid to protect consumers’ health.

TH Group has spent years advocating for clearer labelling regulations, urging authorities to revise the technical standards for dairy ingredient declarations on product packaging. The company has consistently adhered to full disclosure of its raw materials. All of its products are made from pure fresh milk sourced directly from its own dairy farms, processed using world-class technology to preserve the natural purity and nutritional essence of its milk products.

Product traceability is the latest solution in TH Group’s evolving ecosystem of high-tech innovation and scientific management. The company has consistently stressed the crucial role of digital transformation in unlocking the full potential of agriculture. In TH’s strategy, agricultural products must meet two key criteria including competitive pricing and high quality - both of which require high technology.

Thanks to a vast data repository accumulated over the past 15 years, TH Group is now well positioned to implement a comprehensive traceability system. For consumers, scanning a QR code on TH true MILK packaging reveals a journey that begins in the feed crop fields that nourish TH’s nearly 70,000-strong dairy herd.

These fields are maintained by smart irrigation systems that use sensors to monitor soil moisture and adjust water usage accordingly. Crops such as maize, kaoliang, and mombasa and mulato grass are continuously monitored by sensors and AI-powered analytics to ensure optimal nutritional value. TH’s automated machinery performs the work equivalent of hundreds of manual labourers each day.

Each TH dairy cow is installed with an electronic identification chip connected with Afifarm, an advanced Israeli livestock management software. This system provides real-time tracking of each cow’s health, diet, milk output, and reproductive cycle.

TH has also adopted IVF technology for dairy cows, enabling the group to independently breed high-quality herds. Data collected from farm to factory is synchronised, ensuring consistent quality control from the milking stage.

Since it was established, TH’s fresh milk processing plant was equipped with state-of-the-art technology sourced from G7 nations and Europe. It currently produces one million litres per day – a record for Vietnam’s dairy industry.

Particularly, TH Group has applied an enterprise resource planning platform from SAP to manage and analyse real-time data across the entire production chain. This system allows TH to anticipate market demand, adjust production schedules, and accurately plan agricultural activities such as sowing, fertilising, and harvesting, ensuring that product quality remains consistently high.

| TH Group commences construction of foodstuff factory in Thai Binh On February 18, TH Group commenced the construction of a foodstuff factory in Quynh Trang commune in the northern province of Thai Binh’s Quynh Phu district, marking an important milestone on the company's journey to bring consumers nutritious and safe products such as fresh milk, vegetables, and drinking water, among many others. |

| TH Group showcases products at CAEXPO 2024 TH Group, the owner of the TH True Milk brand, is showcasing its high-quality products at the 21st China-ASEAN Expo (CAEXPO) from September 24-28. |

| Thai Huong: a visionary business leader bridging Vietnam and Russia Russian President Vladimir Putin has presented the Order of Friendship to Thai Huong, founder and chairwoman of the Strategic Council of TH Group, and general director of BAC A BANK. |

| Kaluga governor praises TH Group’s world-leading dairy farm Governor of Russia’s Kaluga province visited TH Group’s high-tech dairy farm in Nghe An, the world’s largest closed-loop facility of its kind. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

- Carlsberg Vietnam delivers Lunar New Year support in central region (January 28, 2026 | 17:19)

- TikTok penalised $35,000 in Vietnam for consumer protection violations (January 28, 2026 | 17:15)

Tag:

Tag:

Mobile Version

Mobile Version