What the future holds for logistics industry?

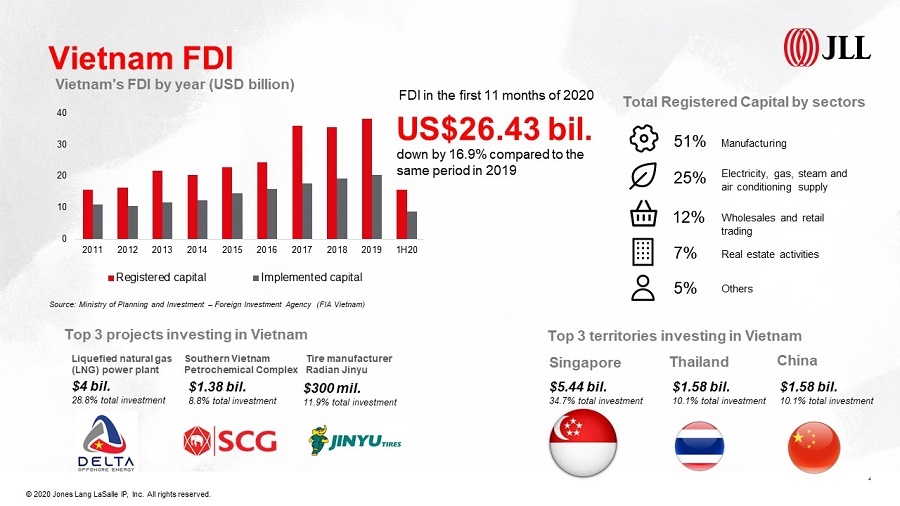

With the global economy being affected by the COVID-19 pandemic, Vietnam drew nearly $16 billion in foreign direct investment in the first six months of 2020, down 15 per cent compared to the same period in 2019, yet much better than the average 30-40 per cent downturn all over the world in 2020, making Vietnam a promising destination for foreign investors.

Particularly, a raft of bilateral and multilateral free trade agreements (FTAs) taking effect as well as the newly signed Regional Comprehensive Economic Partnership (RCEP) and two other FTAs being negotiated make Vietnam one of the most open economies in the world, offering multiple opportunities to develop the supply chain.

As stated by Trang Bui, head of Markets at JLL Vietnam at the CEO Forum, 26 international brands have shifted or expanded production to Vietnam. This figure has enabled Vietnam to benefit the most from the structural change in international supply chain, followed by Taiwan (11 brands). The shift in supply chain has “transformed” Vietnam into a global “warehouse”.

|

| In the first 11 months of 2020, FDI flows into Vietnam reached $26.43 billion |

“Blooming” modern logistics centres

According to JLL Vietnam, in the past 24 months, nearly $3 billion has been injected into the warehouse system and modern logistics centres.

“Investors and businesses used to pay little attention to the lifespan of logistics centres. However, as customers’ requirements are getting stricter, basic infrastructure will not meet their needs. Therefore, investors will need to consider the lifespan and cost-worthiness of logistics centres to better serve supply chains – and construction materials will be a key area of focus to ensure the safety of goods,” commented Bui from JLL Vietnam.

In fact, the number of logistics centres in Vietnam is on the upswing. According to NS BlueScope Vietnam, an industry leader providing high-quality steel solutions for enterprises, recently, every five out of 10 projects provided by BlueScope belong to logistics enterprises such as DHL, Kerry, Mapletree, BW, FM Logistic, or Kizuna.

|

| Kizuna’s ready-to-serve space in Long An uses BlueScope’s Lysaght steel solution with COLORBOND steel Activate technology |

|

| Mapletree Bac Ninh Logistics Centre consists of three Grade A single-storey warehouse blocks applying BlueScope Lysaght steel solution with COLORBOND steel |

According to Le Duy Hiep, chairman of the Vietnam Logistics Business Association, previously, warehouses were of a smaller scale. The current trend is that enterprises team up or top players in the industry invest in large-scale warehouses integrated with multiple functions to form logistics centres.

The second trend is improving administration through IT and automation. The third trend is promoting green logistics powered by renewable energy in the management and operation of logistics centres and warehouses.

Priority on safety and quality

For a well-established company like FM Logistic, the prime concerns when building warehouses are fire safety and the temperature inside the warehouses to ensure the safety of goods and staff.

|

| FM Logistic Bac Ninh is another logistics centre in Vietnam that applies BlueScope’s cutting-edge steel solution |

“Construction materials and technique are two important factors that determine the quality of logistics projects,” Vo Minh Nhut, country president of NS BlueScope Vietnam noted.

| Currently, BlueScope’s COLORBOND steel and Lysaght solutions are not only widely used by factories and warehouses throughout Vietnam but are also present in a variety of projects worldwide. |

The company has invested more than A$100 million ($77.34 million) in the past more than 22 years into research and development to develop its Activate coating technology, setting a new benchmark for the coated steel industry.

Activate is known for its matrix of four-phase protection for the steel substrate integrated in premium COLORBOND steel, completely different from the aluminium-zinc alloy coating two-phase technology in the market, which can prevent corrosion in severe environments like marine and polluted industrial sites.

In addition, this Australian-based steel group has also managed to improve the paint coatings to augment dirt and stain resistance and optimise thermal performance through Clean (self-cleaning technology) and Thermatech (solar reflectance technology), ensuring lasting beauty for construction projects.

|

| BlueScope invested over A$100 million dollars in more than 22 years into R&D to develop Activate coating technology to enhance the lifespan of constructions |

“We offer the Lysaght solution with a synchronised design and completely non-perforated roof connection. The roof system can move freely, helping to prevent disconnection between clip and cladding while the roof can expand or contract under thermal change. This kind of roofing solution is especially suitable for the Vietnamese climate, eliminating leaks and limiting wind uplift. In addition, we also work with strategic partners to ensure aesthetics, quality, and modern look for projects,” Nhut said.

Currently, BlueScope’s COLORBOND steel and Lysaght solutions are not only widely used by factories and warehouses throughout Vietnam but are also present in a variety of projects worldwide. Its solutions encompasses all that is needed for high-quality logistics warehouses, from steel materials with superior durability and quality to excellent roofing, walling, and other innovative solutions that provide optimum efficiency for investors.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

- Carlsberg Vietnam delivers Lunar New Year support in central region (January 28, 2026 | 17:19)

- TikTok penalised $35,000 in Vietnam for consumer protection violations (January 28, 2026 | 17:15)

Tag:

Tag:

Mobile Version

Mobile Version