THACO raises the bar for steel industry

The company, a sub-holding of THACO Group, specialises in the mechanics and supporting industries and is progressively solidifying its market presence by delivering high-quality construction projects that meet the highest technical and aesthetic standards.

THACO Industries owns Vietnam’s largest mechanical complex with a capacity of 200,000 tonnes of steel reserves and surpassing 50,000 tonnes in annual processing, coupled with solid financial and human resources that empower the company to undertake projects of diverse scales including mega structures.

|

THACO Industries has invested in cutting-edge design and simulation software such as Tekla Structures, Sap2000, and AutoCAD to better assess and predict risk and deliver better performance quickly and more easily, and to ensure projects fully comply with strict technical standards and customer requirements.

While the company leverages the extensive expertise of its well-trained employees, experts, and engineers, it also places particular emphasis on automated technology throughout the manufacturing process, evident in a range of sophisticated equipment from Australia, Switzerland, Japan, and South Korea.

This includes the Fibre Laser and CNC Plasma/OxyGas cutting machines; pressure processing lines for bending, punching, and stamping; 100 automated welding robots, and 3-in-1 (welding, drilling, and compressing) technology, as well as surface treatment lines such as shot blasting, ED dipping, powder coating, and more.

In addition, the company applies advanced project management software to optimise supply chains and monitor project progress. The software automatically spots errors and unexpected incidents in production, ensuring that all resources, such as raw materials and labour, are utilised efficiently.

|

The company has consistently adhered to quality and technical standards for steel structure manufacturing and assembly throughout its processing and installation processes.

THACO Industries offers comprehensive solutions throughout a project life cycle, from design and processing to installation and maintenance of MEP systems for industrial, commercial, and civil projects, and can design, construct, and install metal structures, technological production lines, machinery, and equipment for buildings and factories.

|

Its expertise extends to all aspects of MEP systems, such as electrical, fire protection, heating, ventilation, and air conditioning systems, along with water management including supply, treatment, and drainage.

The company is currently a strategic partner to major industrial players like Hoa Phat, Doosan, Dinco, Dai Quang Minh, and PTSC Quang Ngai.

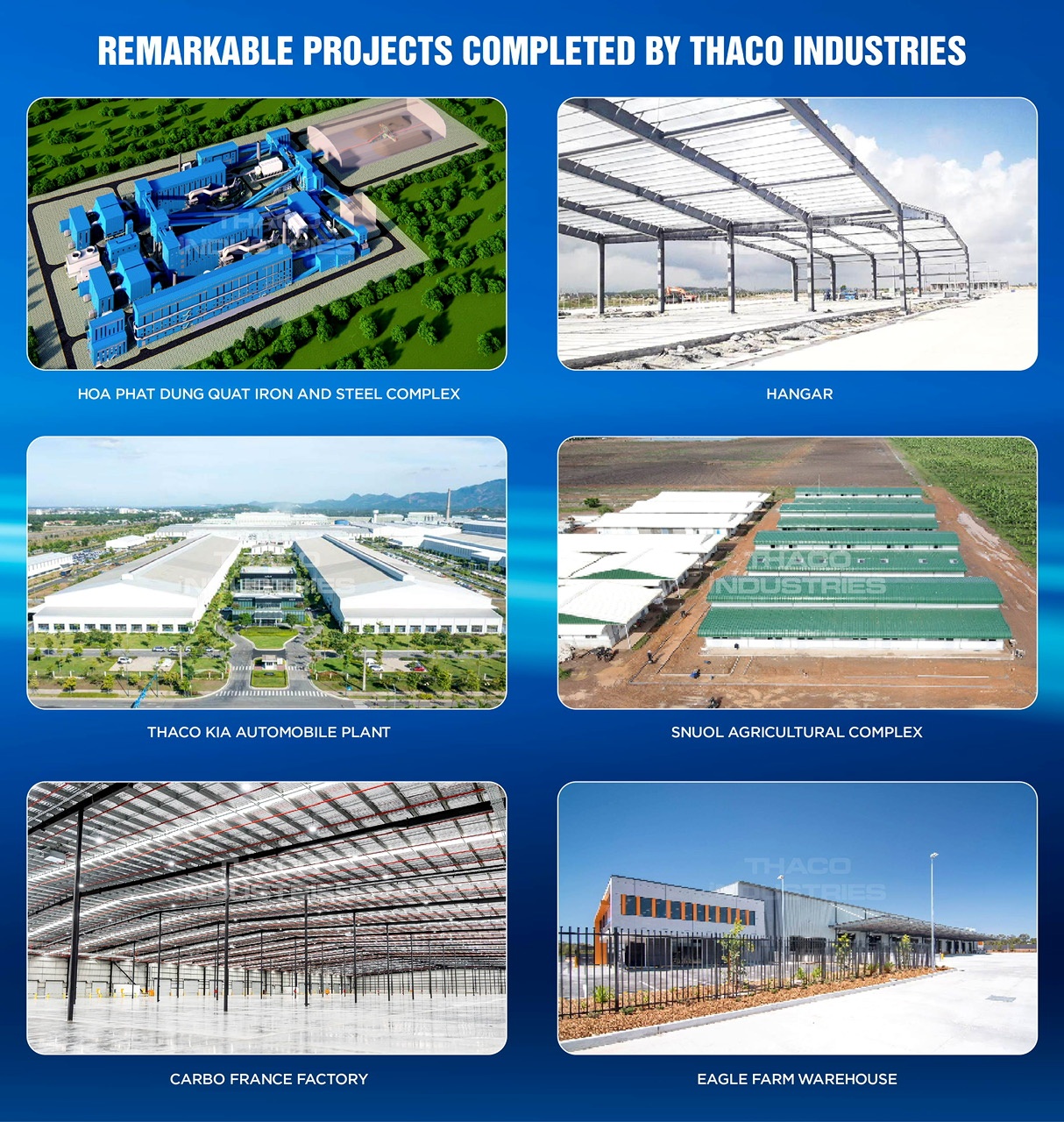

THACO industries has completed more than 100 projects in Vietnam and internationally, including Hoa Phat Pellet Sintering 2 Factory in Quang Ngai province, Ba Son Bridge in Ho Chi Minh City, Chu Lai overpass in Quang Nam province, STS Crane platform for Doosan Vina in Quang Ngai, steel structures for Nghi Son 2 thermal power plant in Thanh Hoa province, Snuol Agricultural Complex in Cambodia, Carbo France Factory in France, and Eagle Farm Warehouse in Australia, plus many more.

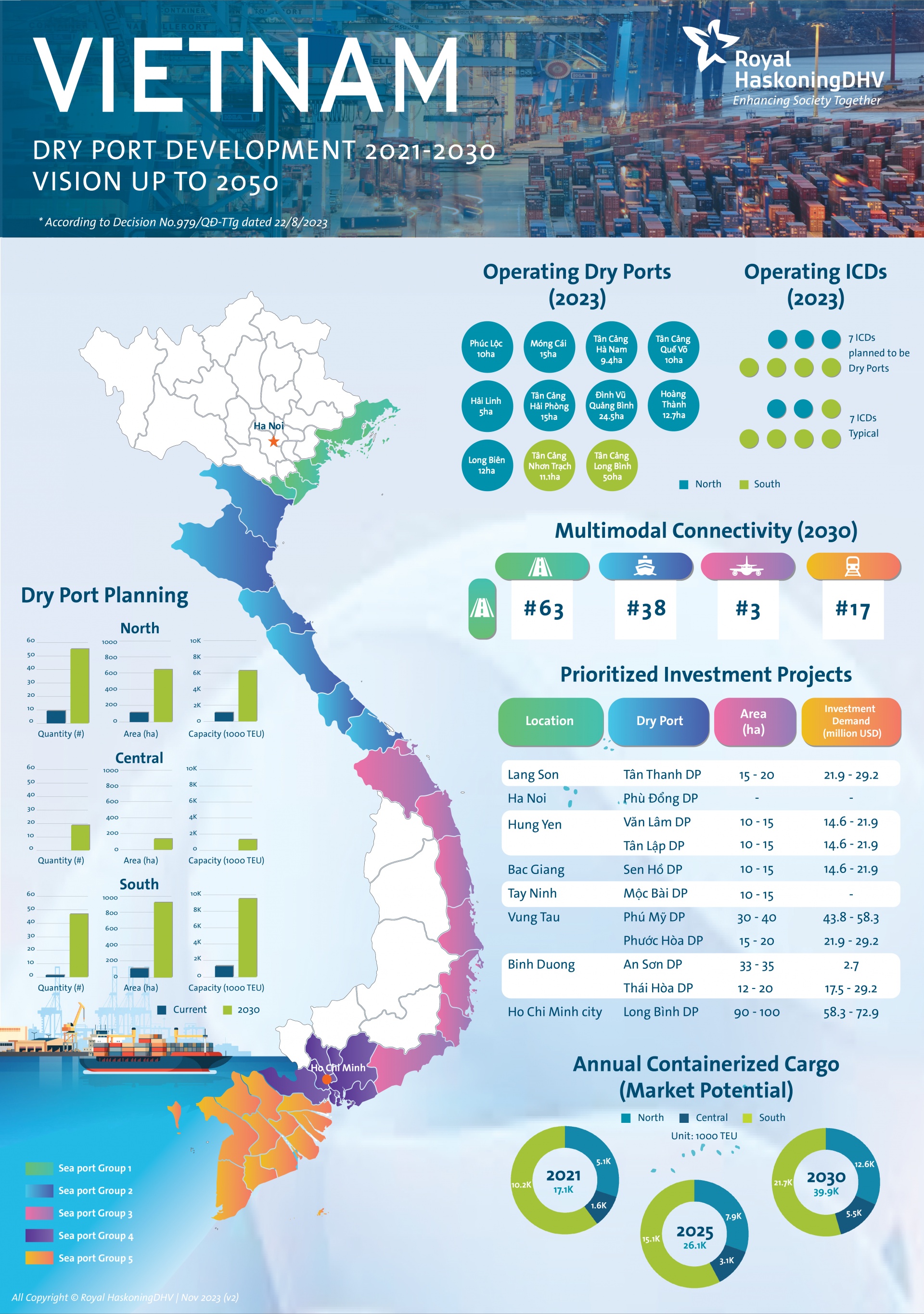

| Vietnam aims for expansive ICD system The country is making strong efforts to develop an expansive inland container depots (ICDs) system to empower the local logistics sector. |

| THACO Group to invest $4.2 billion in circular economy THACO Group has reported significant progress in its Thaco Circular Economy Complex, a project poised to transform Lam Dong province. |

| Cai Mep - Thi Vai Port affirms Vietnam’s maritime position The Cai Mep - Thi Vai International Port in Ba Ria-Vung Tau province plays a crucial role as a gateway connecting maritime trade routes among southern provinces of Vietnam. It also serves as a major international transshipment port, significantly reducing the transportation time between Vietnam and other countries. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- Agro-forestry and fisheries exports jump nearly 30 per cent in January (February 09, 2026 | 17:45)

- Canada trade minister to visit Vietnam and Singapore (February 09, 2026 | 17:37)

- New tax incentives to benefit startups and SMEs (February 09, 2026 | 17:27)

- Vietnam forest protection initiative launched (February 07, 2026 | 09:00)

- China buys $1.5bn of Vietnam farm produce in early 2026 (February 06, 2026 | 20:00)

- Vietnam-South Africa strategic partnership boosts business links (February 06, 2026 | 13:28)

- Mondelez Kinh Do renews the spirit of togetherness (February 06, 2026 | 09:35)

- Seafood exports rise in January (February 05, 2026 | 17:31)

- Accelerating digitalisation of air traffic services in Vietnam (February 05, 2026 | 17:30)

- Ekko raises $4.2 million to improve employee retention and financial wellbeing (February 05, 2026 | 17:28)

Mobile Version

Mobile Version