BASF showcases Germany chemistry innovations

At the 2024 event taking place in Ho Chi Minh City on October 21-23. BASF has joined forces with other German companies to showcase products and solutions and demonstrate how they can create a positive impact on Vietnam’s sustainable future.

|

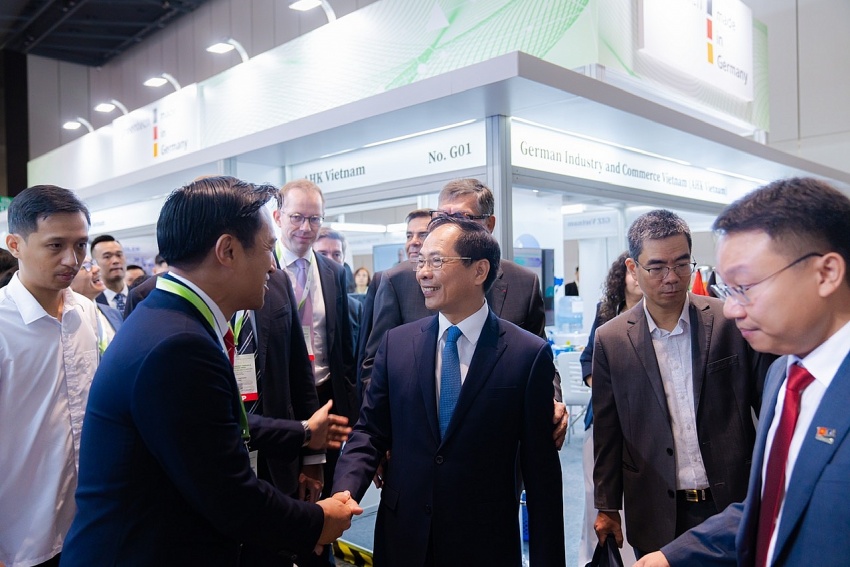

| Deputy Prime Minister, Minister of Foreign Affairs Bui Thanh Son and delegation visited BASF's booth. Photo: BASF |

BASF will introduce a range of its global and local initiatives and a suite of sustainable chemistry solutions designed to support Vietnam’s green transition. Especially, it will deliver a keynote presentation on how to make products circular, sharing insights into the company’s efforts to drive circularity in products and processes.

The company has embedded sustainability into its corporate strategy, aiming for net-zero emissions by 2050, and its strategy emphasises the core initiatives of sustainable energy, carbon abatement, and circularity.

BASF has made significant strides in transitioning to renewable energy. In 2022, renewables accounted for 16 per cent of its global power demand, with an ambitious goal of exceeding 60 per cent by 2030.

The company has also received funding approval for the construction of the world’s largest industrial heat pump for CO2-free steam generation in its headquarters in Germany. The heat pump has the potential to reduce GHG emissions by up to 98 per cent.

BASF is also developing low-emission and emission-free production processes, focusing on key chemicals like hydrogen and methanol. By electrifying these processes, BASF aims to reduce GHG emissions substantially. Through its research, the company is exploring innovative methods that make essential chemicals with minimal carbon impact, a significant advancement for both BASF’s operations and its customers.

In addition, BASF’s circularity initiatives focus on recycling and resource efficiency. The company aims to generate €10 billion ($10.8 billion) in sales through the circular economy by 2030, including products made from renewable or recycled materials. Initiatives such as chemical recycling of plastic waste and the development of new waste-based raw materials showcase BASF’s dedication to closing material loops and extending the life of resources.

A wide variety of sustainable and innovative solutions will be presented to help customers across industries in addressing their own sustainability goals, with a focus on reducing carbon footprint and enhancing recyclability and circularity.

Mechanical recycling is the recovery and processing of plastic waste, transforming it into secondary raw materials for new applications – an essential component of the plastic circularity and enabler for the plastic waste challenge in many countries. However, there are many steps involved, including sorting, washing, granulation, and compounding before the material is ready to be reused. Each step requires different chemistries and technologies for safe and high-quality products.

Many challenges also exist throughout the mechanical recycling value chain. BASF will showcase its comprehensive portfolio to respond to those issues and maximise efficiency and effectiveness in recycling plastic and other materials.

Additional innovations like light stabilisers and flame retardants are specifically designed to enhance performance in agricultural and industrial applications.

Meanwhile, agriculture is a crucial focus for BASF, given its importance in feeding a growing population sustainably while preserving natural resources. The company offers advanced technologies tailored to the specific needs of Vietnam’s agricultural sector, namely to optimise nutrient use, conserve water, and protect soil health.

In addition, by focusing on sustainable agricultural practices, BASF aims to help farmers produce enough food for a growing population while reducing environmental impacts, aligning with the country’s green growth targets, where sustainable farming is increasingly prioritised.

BASF is also supporting Vietnam’s textile and garment industry to better tackle sustainability challenges. It is committed to driving sustainability in the industry, which faces increasing pressure to adopt more eco-friendly practices, especially for those exporting into EU or US markets with stringent health, safety, and environment technical barriers.

BASF is also showcasing a fully recyclable concept for shoes, using materials that allow for 100 per cent recyclability and offer manufacturers enhanced design freedom, resulting in versatile footwear solutions that reduce waste.

For the automotive industry, BASF offers sustainable engineering plastics which are partially bio-based, alongside ChemCycling, a chemical recycling process for plastic waste. Additionally, solutions for high-voltage battery packs in electric vehicles, as well as Haptex 4.0 for polyurethane recycling, support the industry’s shift to cleaner and more sustainable practices.

In construction, BASF will present Elastopir, an energy-efficient insulation for sandwich panels, which provides better indoor climate control and soundproofing while maintaining a low carbon footprint.

BASF’s consumer goods solutions include Emulgade Verde, a green and mild emulsifier for skincare products made from 100 per cent natural feedstock. Other offerings, such as Joncryl for primers and coatings, support reduced solvent emissions and enhance recyclability, contributing to a smaller carbon footprint.

Additionally, BASF will showcase a range of solutions for laundry, industrial cleaning, and textiles.

|

| BASF’s participation at GEFE 2024 exemplifies its commitment to sustainability across various industries. Photo: BASF |

| BASF Vietnam: 30 years of driving sustainable growth through innovation and partnership As BASF celebrates 30 years in Vietnam, Erick Contreras, managing director of BASF Vietnam, talked to VIR’s Quynh Chau on his insights into the company's journey of growth, commitment to sustainability, and vision for the future. |

| BASF Vietnam 30 years of creating chemistry. In Vietnam, with Vietnam Our 30-year journey in Vietnam |

| BASF and Takazuri collaborate to create smart building solutions BASF, a leading supplier, manufacturer, and innovation partner in plastic additives, has partnered with Takazuri to develop smart building solutions supporting climate-resilient construction in Eastern Africa. With a focus on sustainability, these solutions incorporate Takazuri’s Climatile™ technology, which uses locally sourced and converted post-consumer materials. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- Trung Nam-Sideros River consortium wins bid for LNG venture (January 30, 2026 | 11:16)

- Vietnam moves towards market-based fuel management with E10 rollout (January 30, 2026 | 11:10)

- Envision Energy, REE Group partner on 128MW wind projects (January 30, 2026 | 10:58)

- Vingroup consults on carbon credits for electric vehicle charging network (January 28, 2026 | 11:04)

- Bac Ai Pumped Storage Hydropower Plant to enter peak construction phase (January 27, 2026 | 08:00)

- ASEAN could scale up sustainable aviation fuel by 2050 (January 24, 2026 | 10:19)

- 64,000 hectares of sea allocated for offshore wind surveys (January 22, 2026 | 20:23)

- EVN secures financing for Quang Trach II LNG power plant (January 17, 2026 | 15:55)

- PC1 teams up with DENZAI on regional wind projects (January 16, 2026 | 21:18)

- Innovation and ESG practices drive green transition in the digital era (January 16, 2026 | 16:51)

Mobile Version

Mobile Version