TRUMPF Vietnam showcases connected solutions at MTA Vietnam 2019

Smart Manufacturing is the motto of this year's TRUMPF booth at the MTA Vietnam exhibition, the largest and most comprehensive manufacturing solutions trade event, which will take place at the Saigon Exhibition and Convention Centre on July 2-5, 2019.

TruConnect - TRUMPF’s production solutions for Smart Factory

TRUMPF’s focus was virtual reality technology at MTA Vietnam 2018. This year, the hi-tech company will showcase automatic processes under the label of TruConnect, its range of solutions designed to get the most out of Industry 4.0.

By intelligently linking all the different elements in the production system, manufacturers will be able to exploit their full potential.

|

| TRUMPF will introduce Smart Factory concept at MTA Vietnam 2019 |

This concept is TRUMPF’s approach to all-in-one manufacturing, encompassing hardware, software, and services. At the AB4-01 booth, the company’s showcase will portray how manufacturers can take the first step towards a smart factory.

“Visitors will be able to experience TRUMPF’s software solution TruTops Fab QuickJob,” promised TRUMPF’s representative.

The integrated monitoring functions of TruTops Fab Quickjob allow manufactures to track the status of machines and orders as well as to identify optimisation potentials.

In this system, individual customer orders are generated and imported into TruTops Fab QuickJob. All existing orders are automatically collected, nested together with standard parts, and transferred to the production plan. After that, the jobs pass through three process stages of cutting, bending, and marking.

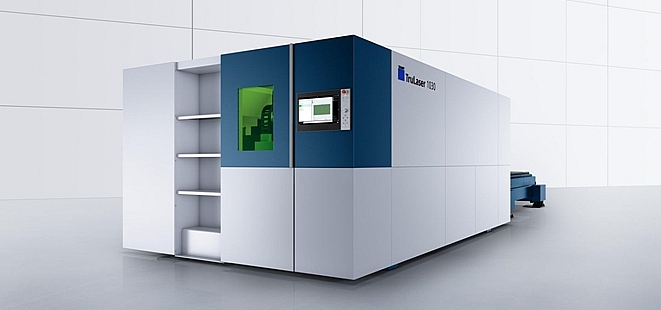

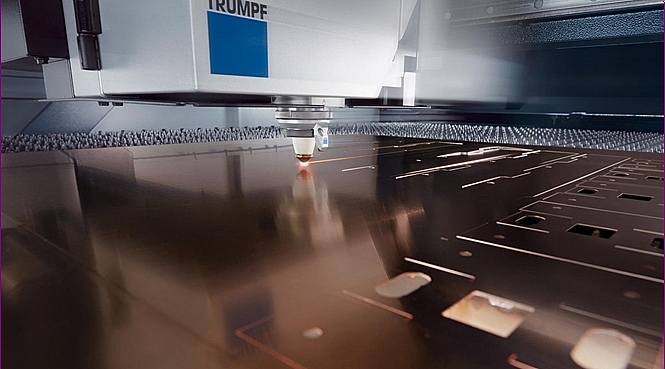

The machines included in these processes are the TruLaser 1030, a reliable and economical 2D laser cutting machine, the TruBend 7036 for high-speed and high-quality bending, as well as the compact TruMark Station 1000 for fast and flexible laser marking.

|

| Visitors to the TRUMPF booth can experience new TruLaser 1000 series for 2D laser cutting |

TruLaser 1030 fiber is equipped with TruDisk– a solid-state laser with a robust design and power that will last for years. The machine also makes the cut with its easy-to-learn operation, as well as numerous intelligent functions.

TruBend 7036 is a prime example of man and machine working in perfect harmony. The ergonomic high-speed machine bends small and medium-sized parts under the best working conditions, saving space for every production system.

When it comes to non-automated and non-motorised systems, with the TruMark Station 1000 marking is performed fast, easily, and flexibly with low material throughput. With a work area that is accessible from three sides, the lightweight work station is ideal for use as a desktop workstation and for mobile use.

TRUMPF: a family-run company with constant innovation and digitalisation

TRUMPF is a market and technology leader in machine tools and lasers for industrial manufacturing. The company’s broad portfolio provides customers with systems for bending, punching, combined punch laser processes, 2D and 3D cutting applications, laser welding, and additive manufacturing.

Thus, TRUMPF offers solutions for customers in leading industries such as switchboard cabinets, elevators, steel furniture, OEM machinery, and food processing. TRUMPF also promotes digital networking in the manufacturing industry through consultation, platform products, and software products.

|

| TRUMPF strives to provide its customers with the best solutions for cost-effective, reliable manufacture of high-quality products |

Since 2006 TRUMPF has been represented in Vietnam. The company has continuously been expanding its local team and presence with a new full legal entity. TRUMPF Vietnam has now more than 40 employees, including general director Patrick Kemnitz from Germany.

The mission of TRUMPF Vietnam is to be close to its customers and support local businesses with sales, spare parts, and services.

More than 20 European-trained engineers are dedicated to install, maintain, and repair machines locally and provide extensive training for customers operating the TRUMPF high-end technology in their manufacturing plants.

The company has production facilities in Germany, France, Great Britain, Italy, Austria, Switzerland, Poland, the Czech Republic, the US, Mexico, China, and Japan.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Vietnam ready to increase purchases of US goods (February 04, 2026 | 15:55)

- Steel industry faces challenges in 2026 (February 03, 2026 | 17:20)

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

Tag:

Tag:

Mobile Version

Mobile Version