BASF India plants receive certification

These plants are the first in India to achieve the REDcert2 standard, an independent third-party audit process, marking a significant milestone in BASF’s commitment to sustainability and environmental stewardship.

This certification enables BASF to supply certified low-carbon-footprint dispersions through the biomass balance (BMB) approach that perform identically to fossil-based dispersions.

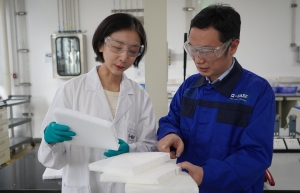

According to Andreas Fechtenkoetter, senior vice president, Dispersions Asia Pacific of BASF, achieving REDcert2 certifications for its dispersion plants in India underscores commitment to driving sustainability and innovation as an industry leader.

With India’s continued prioritisation of CO2 reduction, BASF is seeing a growing demand for sustainable products in the country.

The Indian government has committed to achieve net-zero emissions by 2070.

Milind Joshi, business director, Dispersions (South Asia) from BASF said that with these REDcert2-certified dispersions plants in operation, BASF was well-positioned to supply biomass-balanced dispersions to its customers in the country and support their sustainability plans.

“By adopting our low-carbon-footprint solutions, customers are not only differentiating themselves from competitors but also contributing to the larger goal of combating climate change,” Joshi said.

The two certified dispersion plants in India bring the number of BASF dispersion plants in the Asia Pacific region that have received REDcert2 certification to five. This accomplishment has strengthened BASF’s ability to meet the growing demand for low-carbon-footprint solutions across various industries.

|

| BASF dispersions in India received REDcert certification |

In BASF’s biomass balance approach, renewable raw materials are used as feedstock in the very first steps of chemical production.

The proportion of renewable raw materials utilised is then allocated to specific sales products using a mass balance method certified by REDcert².

The certification system confirms that for the biomass balanced product, BASF has replaced relevant quantities of fossil-based resources with renewable feedstock.

REDcert² standard complies with the EU Directive on Renewable Energy and ensures correct attribution of renewable resources to the final products. The initiative supports BASF customers in India looking to commit to a low-carbon-footprint roadmap

| BASF and Teamplas to recycle consumer waste BASF and Teamplas Group, a leading manufacturer of recycled pellets in Southeast Asia, on November 14 announced that they have collaborated to transform post-consumer waste into new high-quality office equipment and car interior parts with the help of BASF's IrgaCycle®. |

| BASF launces new interactive online chemistry experiments BASF launched two new interactive chemistry experiments in Vietnamese on its popular online platform BASF Virtual Lab on December 6. |

| BASF launches new anti-scorch solution BASF has launched its new anti-scorch solution, Irgastab PUR 71, which offers exceptional performance and a superior environmental, health, and safety profile. The new product meets the increasingly stringent regulatory demands on substance classification and sustainability. |

| BASF celebrates inauguration of TPU plant at the Zhanjiang Verbund site BASF celebrated the inauguration of its Thermoplastic Polyurethane (TPU) plant at the Zhanjiang Verbund site on January 18. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- Bac Ai Pumped Storage Hydropower Plant to enter peak construction phase (January 27, 2026 | 08:00)

- ASEAN could scale up sustainable aviation fuel by 2050 (January 24, 2026 | 10:19)

- 64,000 hectares of sea allocated for offshore wind surveys (January 22, 2026 | 20:23)

- EVN secures financing for Quang Trach II LNG power plant (January 17, 2026 | 15:55)

- PC1 teams up with DENZAI on regional wind projects (January 16, 2026 | 21:18)

- Innovation and ESG practices drive green transition in the digital era (January 16, 2026 | 16:51)

- Bac Ai hydropower works stay on track despite holiday period (January 16, 2026 | 16:19)

- Fugro extends MoU with PTSC G&S to support offshore wind growth (January 14, 2026 | 15:59)

- Pacifico Energy starts commercial operations at Sunpro Wind Farm in Mekong Delta (January 12, 2026 | 14:01)

- Honda launches electric two-wheeler, expands charging infrastructure (January 12, 2026 | 14:00)

Mobile Version

Mobile Version