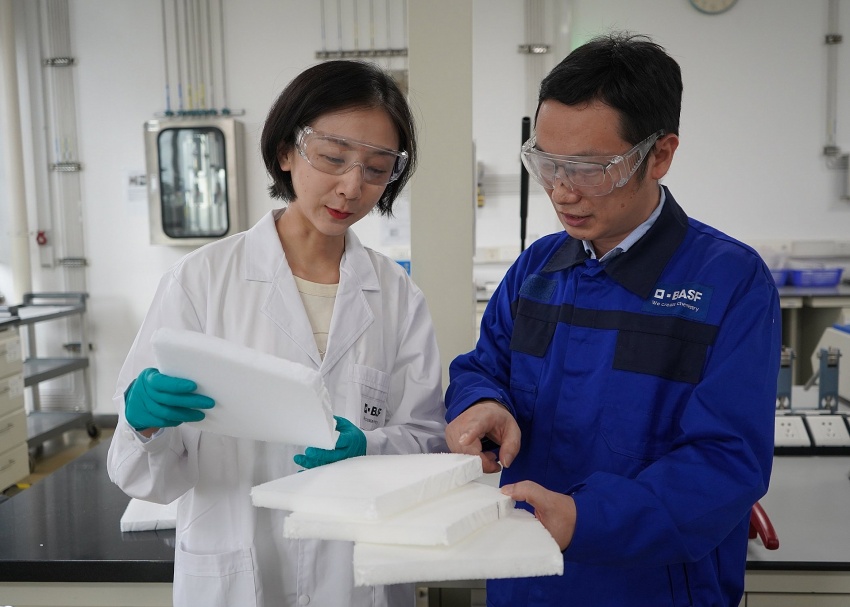

BASF launches new anti-scorch solution

|

Launched on December 12, the premium solution has been formulated without aromatic amine, addressing the limitations of conventional anti-scorch additives effectively.

According to Dr. Bettina Sobotka, head of Global Marketing and Development, Plastic Additives from BASF, Irgastab PUR 71 reaffirms BASF's commitment to innovation and partnership within the industry.

“We offer our customers a sustainable alternative to conventional solutions, empowering them to gain a significant advantage in the ever-changing global market,” said Sobotka.

“With a proven track record and backed by our global team of dedicated experts, we strive to pioneer cutting-edge technologies and solutions that not only enhance performance, but also promote sustainability,” she added.The heat generated during the polyurethane foam manufacturing process can cause discolouration, loss of mechanical properties, and even fire hazards if the polyols, the main raw materials, are not properly stabilised.

While conventional anti-scorch packages rely on phenolic antioxidants combined with aromatic amine stabilisers, they come with significant drawbacks such as unpleasant odour, toxicity concerns, or high volatility.

The use of anti-scorch additives can greatly minimise degradation caused by exothermic reactions during the processing of PUR foam.

As Irgastab PUR 71 is formulated without aromatic amine, it effectively decreases emissions and lowers the potential harm to both humans and aquatic life. This leads to significantly reduced levels of volatile organic compounds and condensable emissions released from PUR foams. Due to these properties, air quality within the interior of vehicles can be greatly improved, creating an advantage in the automotive industry.

Irgastab PUR 71 provides targeted application benefits for various industries. It enables lower emissions in compliance with the most stringent automotive industry specifications and improves the air quality of vehicle interiors.

It also offers state-of-the-art anti-scorch resistance to polyol as well as foam producers, preventing heat degradation during the foaming process. In addition, it has no carcinogenic, mutagenic and reprotoxic classification, allowing polyol producers to comply with environmental voluntary certifications and keep their anti-scorch recipe confidential.

For consumer goods, it enhances product quality by providing improved whiteness and resistance to colour change caused by gas fading and light-induced discolouration.

Irgastab PUR 71 is part of the VALERAS portfolio. With VALERAS, BASF is committed to increasing the sustainability of plastics along the entire polymer value chain with innovative solutions and offerings from its plastic additives business.

| BASF launches first biomass balance plastic additives BASF on October 3 launched the industry’s first biomass balance offerings for plastic additives. |

| BASF and Teamplas to recycle consumer waste BASF and Teamplas Group, a leading manufacturer of recycled pellets in Southeast Asia, on November 14 announced that they have collaborated to transform post-consumer waste into new high-quality office equipment and car interior parts with the help of BASF's IrgaCycle®. |

| BASF launces new interactive online chemistry experiments BASF launched two new interactive chemistry experiments in Vietnamese on its popular online platform BASF Virtual Lab on December 6. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Agro-forestry and fisheries exports jump nearly 30 per cent in January (February 09, 2026 | 17:45)

- Canada trade minister to visit Vietnam and Singapore (February 09, 2026 | 17:37)

- New tax incentives to benefit startups and SMEs (February 09, 2026 | 17:27)

- Vietnam forest protection initiative launched (February 07, 2026 | 09:00)

- China buys $1.5bn of Vietnam farm produce in early 2026 (February 06, 2026 | 20:00)

- Vietnam-South Africa strategic partnership boosts business links (February 06, 2026 | 13:28)

- Mondelez Kinh Do renews the spirit of togetherness (February 06, 2026 | 09:35)

- Seafood exports rise in January (February 05, 2026 | 17:31)

- Accelerating digitalisation of air traffic services in Vietnam (February 05, 2026 | 17:30)

- Ekko raises $4.2 million to improve employee retention and financial wellbeing (February 05, 2026 | 17:28)

Tag:

Tag:

Mobile Version

Mobile Version