BASF celebrates inauguration of TPU plant at the Zhanjiang Verbund site

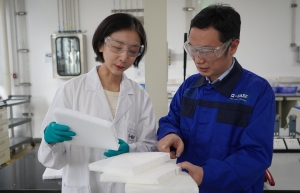

The new plant is the largest single TPU production line for BASF globally. The smart factory is built with advanced technologies, including automated guided vehicles and advanced automation systems, that translate into efficiency improvements.

According to Dr. Martin Jung, president of Performance Materials at BASF, the plant will enable BASF to meet the growing market demand for TPU in Asia-Pacific, particularly in the Industrial, eMobility, and new energy segments, while also moving it closer to key customer industries in China and Asia-Pacific.

“With this plant, we will strengthen the supply of innovative and recyclable Elastollan TPU solutions in Asia and continue our plastics journey towards a more sustainable future,” Jung added.

|

Along with the Zhanjiang Verbund site’s first plant, which was inaugurated in 2022 to produce engineering plastics compounds, the innovations coming from its Creation Centers and an extensive research and development (R&D) network in Asia-Pacific position BASF well to meet the growing demands of its customers across the region for innovative material solutions.

BASF’s R&D network provides engineering, simulation, and manufacturing know-how to help drive innovation and product development in tandem with market demand and trends such as the electrification of cars and the miniaturisation of electronic devices.

Haryono Lim, president of Mega Projects Asia at BASF, said that the company’s strategy is to produce where its customers are.

| “Thanks to the strong support from the Chinese government, our employees, and partners, the Zhanjiang Verbund site project has been progressing steadily as planned and has now concluded the construction of its initial phase,” said Lim. |

“The site is now focusing on a steam cracker and several downstream plants to produce petrochemicals and intermediates, among others. BASF is dedicated to building the Zhanjiang Verbund site into a role model of sustainable and smart production,” Lim added.

Dr. Jeffrey Lou, president and chairman of BASF Greater China, commented that as the largest chemical market in the world, China plays a vital and strategic role for BASF.

“This milestone in the Zhanjiang Verbund site project highlights BASF’s robust development in China and our dedication to being close to our local customers,” said Lou. “With the increased local production capabilities and strong commitments to sustainability, we can provide more innovative solutions with lower carbon footprints to our customers in China.”

|

BASF plans to power the entire Zhanjiang Verbund site with 100 per cent renewable energy by 2025.

The new Verbund site will be BASF’s largest investment to date, worth around $10.9 billion upon completion.

It will be operated under the sole responsibility of BASF and will be the company’s third-largest Verbund site worldwide, following Ludwigshafen, Germany, and Antwerp, Belgium.

Elastollan TPU is a versatile material widely used in various industries, including automotive, consumer electronics, footwear, sports and leisure, healthcare, and industrial cables and wires.

In the eMobility segment, Elastollan TPU provides flexibility and long-term durability for cable sheaths.

Due to its exceptional properties such as high strength, flexibility, and resistance to abrasion, TPU is an ideal choice for a broad range of applications. The growth of the TPU market, in particular for high-end applications, is driven by several factors, including increasing regulatory requirements and growing customer expectations for enhanced sustainability and performance.

| BASF and Teamplas to recycle consumer waste BASF and Teamplas Group, a leading manufacturer of recycled pellets in Southeast Asia, on November 14 announced that they have collaborated to transform post-consumer waste into new high-quality office equipment and car interior parts with the help of BASF's IrgaCycle®. |

| BASF launces new interactive online chemistry experiments BASF launched two new interactive chemistry experiments in Vietnamese on its popular online platform BASF Virtual Lab on December 6. |

| BASF launches new anti-scorch solution BASF has launched its new anti-scorch solution, Irgastab PUR 71, which offers exceptional performance and a superior environmental, health, and safety profile. The new product meets the increasingly stringent regulatory demands on substance classification and sustainability. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- MAE names big 10 policy wins in 2025 (February 06, 2026 | 08:00)

- US firms deepen energy engagement with Vietnam (February 05, 2026 | 17:23)

- Vietnam records solid FDI performance in January (February 05, 2026 | 17:11)

- Site clearance work launched for Dung Quat refinery upgrade (February 04, 2026 | 18:06)

- Masan High-Tech Materials reports profit: a view from Nui Phao mine (February 04, 2026 | 16:13)

- Hermes joins Long Thanh cargo terminal development (February 04, 2026 | 15:59)

- SCG enhances production and distribution in Vietnam (February 04, 2026 | 08:00)

- UNIVACCO strengthens Asia expansion with Vietnam facility (February 03, 2026 | 08:00)

- Cai Mep Ha Port project wins approval with $1.95bn investment (February 02, 2026 | 16:17)

- Repositioning Vietnam in Asia’s manufacturing race (February 02, 2026 | 16:00)

Tag:

Tag:

![[Infographic] AMATA: Industrial and Smart City Developer](https://vir.com.vn/stores/news_dataimages/2026/022026/12/16/croped/amata-industrial-and-smart-city-developer-20260212165823.jpg?260212050401)

Mobile Version

Mobile Version