Vietnam a key partner of Taiwan's textile industry

|

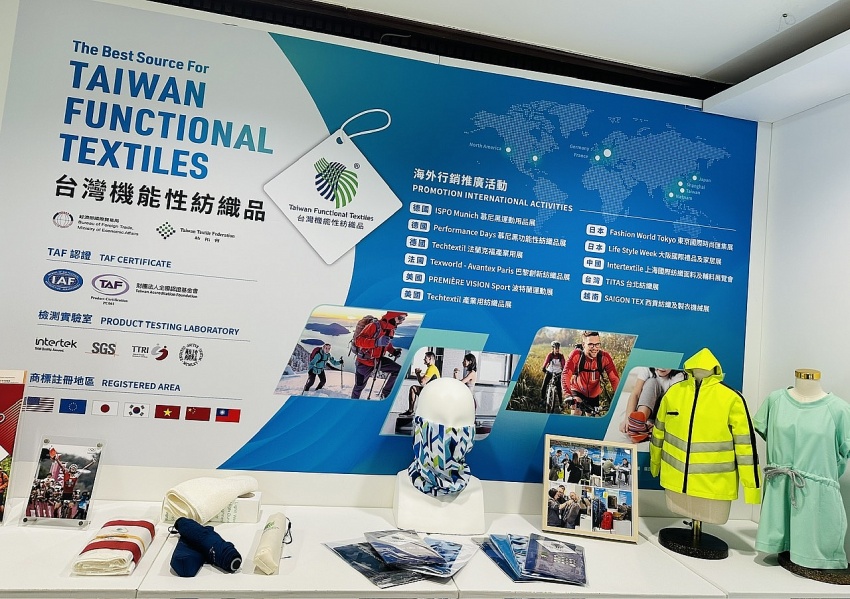

| Sources for Taiwan functional textiles |

Taiwan’s textile industry mostly focuses on the upper- and mid-stream sectors. Vendors in the lower-stream sector are mostly located overseas to serve clients around the world. There are 4,400 factories engaged in textile and garment manufacturing in Taiwan, employing about 140,000 people. The upper- and mid-stream sectors contribute 95 per cent of the total value.

The Taiwanese textile industry has strategically established an extensive overseas manufacturing network to supply clients primarily in Europe and North America. Taiwan’s domestic production value was about $12.7 billion in 2023, while its overseas production value was approximately $29.8 billion.

Of this, Vietnam was the largest export market for textiles, with exports amounting to $1.7 billion, accounting for 26 per cent of total textile exports. The entire ASEAN region made up 44 per cent of the total 2023 textile export performance, China and Hong Kong covered 17 per cent, North America 11 per cent, and Japan and South Korea 5 per cent.

Speaking to VIR at the press conference on July 22 in Taipei about the relationship between Vietnam and Taiwan’s textile industry, Justin Huang, president of the Taiwan Textile Federation (TTF), stated that Vietnamese textile and garment businesses are close friends with Taiwan’s partners in the industry. Every year, alternating locations, The TTF and the Vietnam Textile and Apparel Association organise a textile forum. Last year, it was held in Ho Chi Minh City.

“Last year we discussed sustainable solutions, how textile facilities can develop solutions, what kind of products they will develop, and what markets they will serve next. We shared Taiwan’s experiences with our Vietnamese friends,” Huang said.

“Vietnam’s market, with more than 100 million people, is full of potential for consumption and also for labour force,” he highlighted, comparing the advantages of Vietnam’s textile industry to Taiwan’s. “Materials and various types of fabrics from Taiwan are shipped to Vietnam to make perfect products, which are then shipped to the United States. Vietnamese labour is very skilful, especially for complicated items that can only be made in Southeast Asian countries like Vietnam, Cambodia, and Indonesia.”

Discussing the growth of Taiwan’s textile industry, Huang said the TTF is funded entirely by private companies or associations, without any government funding.

“Every year, we submit proposals to get some funding for research. If we have positive results, the government, through the Ministry of Internal Affairs, will push for the technology transfer to interested textile sectors. Once deemed worthy, the government approves the proposals and funds the project,” Huang said.

|

Taiwan embarked on an innovation journey around their fabrics, Huang said. It used new technologies to innovate fibres, fostering cross-industry cooperation for new applications of textile interface materials, establishing certifications for functional and technical textiles, utilising branding strategies to develop high-value textiles, and developing a total solution business.

To align with these trends, Taiwan’s textile industry will focus on digitalisation (through smart manufacturing, sewing technology, AIoT technology, template sewing, and 3D body mapping); innovation (with breathable and waterproof fabrics, multiple functions and microfiber, moisture-conductive materials, dope-dyed/waterless dyeing, digital printing, optimised bonding technology, and smart clothing); and decarbonisation (by recycling PET bottles, recycled nylon, converting carbon to PET yarns, starting with raw materials and product design) and applying green energy.

Huang said the objective was to establish Taiwan as a global innovative functional and technical textiles player. This was in line with the trend of leading international sports brands to use recycled material incrementally and Taiwan's many other goods produced sustainably.

"Functional fabric material has become popular among sports brands in international championships such as the Football World Cup and the Olympics. During the soccer World Cup in South Africa in 2010, a mere 9 per cent of teams wore functional material (recycled) but at the Paris Olympics, a whopping two-thirds of athletes were expected to wear these kits," he said.

Fashion brands like Nike have set goals by 2025 to use environmentally friendly materials for 50 per cent of their raw materials and recycle 80 per cent of waste from the supply chains. Adidas plans to reduce the carbon footprint of each product by 15 per cent, with 90 per cent of products made from sustainable materials.

Patagonia aims for its entire supply chain to be carbon neutral, with all clothing made from 100 per cent recycled or recyclable materials. The North Face plans for 50 per cent of the nylon and polyester used in its products to be made from recycled materials.

| Vietnam benefits from China+1 policy shift Chinese and Taiwanese groups continue to seek strategic investment opportunities in Vietnam as the country emerges as one of the top gainers from the China+1 strategy. |

| Taiwan aims to become global supply chain centre in six key industries Taiwan's Ministry of Economic Affairs' (MoEA) Industrial Development Administration has highlighted semiconductors, AI healthcare, machine tools, electric vehicles (EVs), bicycles, and textiles as six of its outstanding industries. |

| Quality Vietnamese apparel still favoured abroad Vietnam’s biggest apparel association has denied that the garment and textile industry is losing its competitive advantage in the United States. |

| Nam Dinh inaugurates its largest textile factory to date TOP Textile JSC held an inauguration ceremony for its $203 million textile and dyeing factory in the northern province of Nam Dinh on July 13, marking an important milestone for the company in Vietnam. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- SK Innovation-led consortium wins $2.3 billion LNG project in Nghe An (February 25, 2026 | 07:56)

- THACO opens $70 million manufacturing complex in Danang (February 25, 2026 | 07:54)

- Phu Quoc International Airport expansion approved to meet rising demand (February 24, 2026 | 10:00)

- Bac Giang International Logistics Centre faces land clearance barrier (February 24, 2026 | 08:00)

- Bright prospects abound in European investment (February 19, 2026 | 20:27)

- Internal strengths attest to commitment to progress (February 19, 2026 | 20:13)

- Vietnam, New Zealand seek level-up in ties (February 19, 2026 | 18:06)

- Untapped potential in relations with Indonesia (February 19, 2026 | 17:56)

- German strengths match Vietnamese aspirations (February 19, 2026 | 17:40)

- Kim Long Motor and AOJ Suzhou enter strategic partnership (February 16, 2026 | 13:27)

Tag:

Tag:

Mobile Version

Mobile Version