Bosch showcases latest automation technology at Propak Vietnam 2018

|

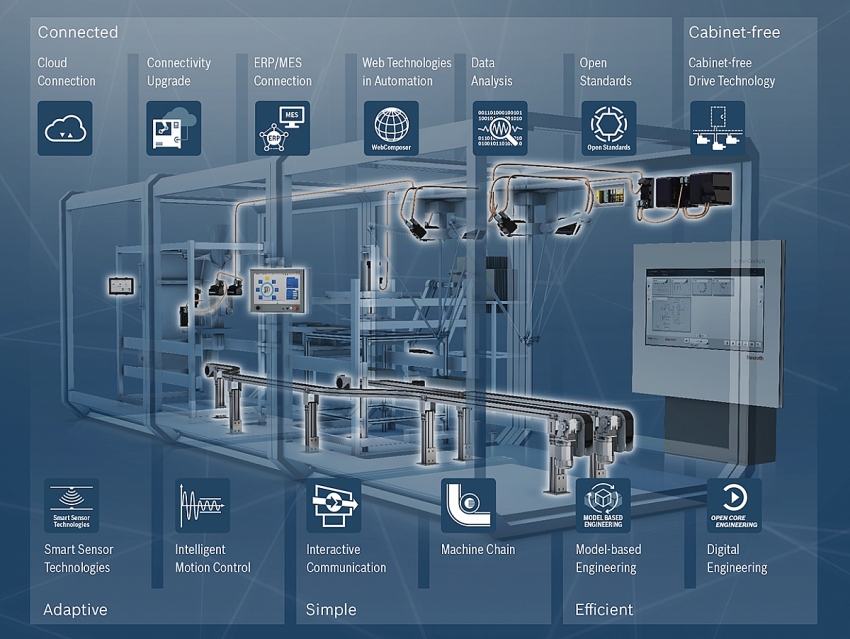

| Propak Vietnam 2018 will allow visitors to experience a selection of Rexroth’s innovative exhibits |

At Booth F30 at Saigon Exhibition and Convention Centre (SECC) in Ho Chi Minh City’s District 7, visitors will experience a selection of Rexroth’s innovative exhibits that demonstrate the benefits of connectivity in a variety of manufacturing and assembly operations—from manual to fully automated.

Bosch Rexroth’s latest advancements, from Open Core Engineering to new IoT Gateway, a technology which makes it easy for manufacturers to add connectivity to existing machines and equipment, serve as a highlight of the show.

Further “connected” exhibits and demonstrations feature the new high-speed, high-precision VarioFlow plus plastic chain conveyor systems, Nexo tightening systems, new Active Cockpit production floor data visualisation system and more.

The following are some exhibited products and demo highlights.

Smart factory technology will be presented with an appearance by Rexroth‘s ActiveCockpit, interactive communication platform for the manufacturing industry.

As an interactive communication platform, ActiveCockpit processes and visualises production data in real time. ActiveCockpit networks IT applications such as production planning, quality data management, and e-mailing with the software functionality of machines and plants.

The information is the basis for decisions and process improvements.

The IoT Gateway makes it easy to connect to Industry 4.0 environments without intervening in the automation logic.

The precisely coordinated combination of control hardware and software for implementing IT applications collects sensor and process data, transmits it to MES (Manufacturing Execution System), cloud applications or local machine state monitoring systems, for example, and enables process data analysis.

OpenCore Engineering combines PLC-based engineering and IT automation. This integrated approach is made possible by the Open Core Interface, the significant expansion of our solutions for machine automation.

With the Open Core Interface, Bosch Rexroth is providing a software interface that is unique as it permits enhanced access to the control core, offering numerous programming languages and allowing the integration of smart devices into automation systems.

In addition, individual real-time control functions can be independently created.

Cabinet-free automation technology—Decentralised Servo drives IndraDrive Mi: IndraDrive Mi enables machine manufacturers to integrate all electrical drive components directly into the machine. This saves space and reduces wiring effort by up to 90 per cent.

The latest in high-precision tightening technology—Bosch Rexroth’s Nexo cordless nutrunner. Nexo offers a direct measuring system for accurate torque and angle detection.

Combining economical operation and safety critical tightening capability, Bosch Rexroth’s Nexo nutrunner can handle the most demanding applications and is suitable for both large and small scale production.

Its decentralised intelligence is located directly onboard the tool which enables operation without cable connections or the need for an external controller. By integrating the control of the tightening process, the highest level of reliability is possible—even in wireless dead zones.

| With a wide range of load and speed capabilities,Rexroth's linear motion system is scalable from small laboratories to large warehousing or aircraft assembly operations. |

Bosch Rexroth’s linear motion technology: EasyHandling—Linear Module System—a complete platform for the easy design, construction, and commissioning of Cartesian motion robots (also known as linear robots).

It combines open, user-friendly programming environments with precise and reliable linear componentry to create the most accessible, easy-to-use Cartesian motion robot.

Modular plastic chain conveyor VarioFlow plus is a flexible, modular plastic chain conveyor system used for moving high volume packaged goods and other consumer goods, such as packaged foods, pharmaceuticals, and healthcare products.

VarioFlow plus chain conveyor system is optimised for quick assembly and convinces by particularly low-noise, economical operation with which multi-axis control has never been easier.

Rexroth’s Open Mechatronics Demo demonstrates this by utilising Open Core Engineering to control a multi-axis Cartesian system.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

- Carlsberg Vietnam delivers Lunar New Year support in central region (January 28, 2026 | 17:19)

- TikTok penalised $35,000 in Vietnam for consumer protection violations (January 28, 2026 | 17:15)

Tag:

Tag:

Mobile Version

Mobile Version