Airbus updates commercial programmes to prepare for recovery stage

|

| A321LR in Flight |

Airbus has this month hosted an update on the pandemic effects on its airliner business and the preparation for the recovery.

According to Christian Scherer, CCO and head of International at Airbus, the COVID-19 pandemic has put the airliner business in its most profound decline ever, losing the industry 25 years of growth.

The pandemic’s effects on air travel have hit international travel the hardest, with present traffic levels, AvailableSeat Kilometres (ASKs) are at 27 per cent of 2019 levels and domestic ASKs at 80 per cent. Overall the decline is 51 per cent.

Like others, Airbus had to adapt to the pandemic in daily life, had to adapt to the pandemic in the working environment in the company. It had to adapt it for its customers and it kept delivering aircraft.

Airbus delivered 566 airplanes last year, which came after the decision to scale down its production by significant amount, about 40 per cent on the single aisles, and a little bit more than that on the widebodies.

The European aircraft maker last month gave its supply chain a firm forecast for the coming years so that suppliers can adapt in time for production increases. It predicts the recovery to happen in 2023 for domestic traffic and 2024 to 2025 for international traffic.

“We do believe if we now look to the future, you can imagine that a company like ours with many of our stakeholders, is trying to model the corridor of recovery because we are in a recovery,” said Christian Scherer.

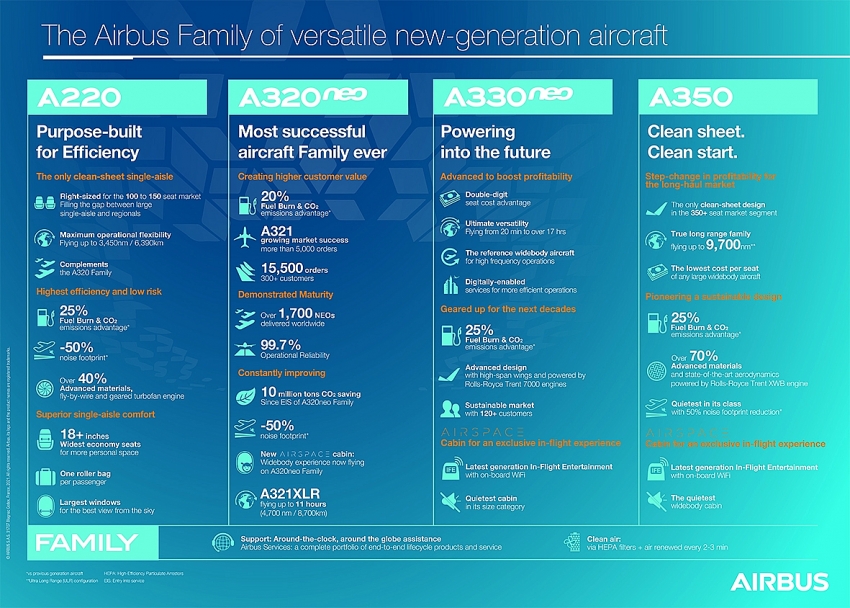

Aircraft family update

|

To prepare for the recovery, Airbus is updating its product portfolio, and the production ramp and latest technical developments.

A220

The present monthly production rate is a total of five from the Mirabel and Mobile final production lines, with a gradual increase to six in early 2022. The plan is to ramp the A220 series to rate 14 by mid-decade.

|

| A220 Family |

The A220-300 has a maximum takeoff weight (MTOW) increase to 70.9t later this year, increasing the nominal range to 3,550nm.

A320

The present monthly production rate is 40 aircraft per month. This increases to 45 by the end of 2021, rate 64 during 2023, and finally rate 70 by Q1/2024. The supply chain has been asked to give feedback on rate 75 by 2025.

The attention is on the A321XLR that has started production and will enter the FAL in Hamburg end of 2021. Flight tests will be happening during 2022 and first deliveries in 2023.

A330 and A350

The monthly production rate for the A330 remains at rate two until further. The A350 gradually ramps from rate five to six at the end of next year.

|

The first A330-900 with 251 tonnes of maximum takeoff weight (MTOW) was delivered to CORSAIR in March.

Airbus is making further improvements on the A350. The MTOW of the A350-900 has increased to 280 tonnes and for the -1000 to 319 tonnes. A weight-saving programme called P7 is ongoing to increase the range further. These developments will benefit the Ultra Long Haul Sunrise project that QANTAS and Airbus hope to rekindle as international travel restarts.

New A320/A321 final assembly line in Toulouse

A321 XLR is now in the making and Airbus will lead to flight testing in 2022 and to an entry into service of the aircraft in 2023.

|

Sustainability – Ready for future journey

Philippe Mhun, executive vice president of Programmes & Services for Airbus, said, “We are ready now to address the challenges of what sustainability means for the aviation industry for the years and decades to come. We're looking at each and every one of our products to reduce fuel consumption and CO2 emissions by 20-30 per and NOx emissions by 50 per cent in most of cases.”

He pointed out that reduced fuel consumption equals reduced CO2 emissions (one kg of burned jet fuel generates 3.2 kg CO2) and since 1990, Airbus reduced emissions per passenger per km by 50 per cent, a significant progress.

However, the EVP added that achieving net-zero emissions by 2050-2060 would need additional efforts. Airbus will have its entire fleet ready for a 50 per cent SAF blend (sustainable aviation fuel, a CO2 neutral fuel made from non-fossil sources) soon, and a hydrogen-fuelled airliner should be ready by 2035. To this end, Airbus has announced the creation of a hydrogen tank centre in Bremen, Germany and another one in Nantes, France.

|

| Airbus Zero Emission Formation Flight |

Airbus expects SAF to solve 50 per cent of the problem with emissions, with new technologies like hydrogen taking care of 42 per cent and the remaining 8 per cent to come from improved ATM and aircraft operations, and other operational enhancements.

“We are ready to have this wonderful journey with the wider ecosystem. We're delivering a lot of value to our customers, and we still invest in our current product and services portfolio. In parallel, we are developing the maturity of the technology, which are being required to support zero net emissions by 2050 with a launch potentially in the middle of the next decade,” Mhun noted.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Ho Chi Minh City attracts nearly $980 million in FDI in early 2026 (March 02, 2026 | 10:57)

- Japan’s Fujiya strengthens production base in Vietnam (February 28, 2026 | 09:00)

- Haiphong gains new growth impetus from strategic planning and integrated infrastructure (February 27, 2026 | 16:40)

- Kurz Vietnam expands Gia Lai factory (February 27, 2026 | 16:37)

- SK Innovation-led consortium wins $2.3 billion LNG project in Nghe An (February 25, 2026 | 07:56)

- THACO opens $70 million manufacturing complex in Danang (February 25, 2026 | 07:54)

- Phu Quoc International Airport expansion approved to meet rising demand (February 24, 2026 | 10:00)

- Bac Giang International Logistics Centre faces land clearance barrier (February 24, 2026 | 08:00)

- Bright prospects abound in European investment (February 19, 2026 | 20:27)

- Internal strengths attest to commitment to progress (February 19, 2026 | 20:13)

Tag:

Tag:

Mobile Version

Mobile Version