Tungsten recycling in advanced battery technologies

By combining the strengths of HCS and Nyobolt, this cooperation not only creates future synergies for both companies but also fosters the growth of a circular economy and sustainable development in the battery industry.

With the vision of becoming a high-tech, value-added business by developing new tungsten applications that are critical for the technologies of the future, Germany-based H.C. Starck Tungsten Powders (HCS) has announced the signing of definitive agreements to invest almost $54 million into Nyobolt Ltd. – a fast-charging Li-ion battery solutions company that leverages HCS’s advanced tungsten materials in its anode – for a 15% equity interest on a fully diluted basis.

|

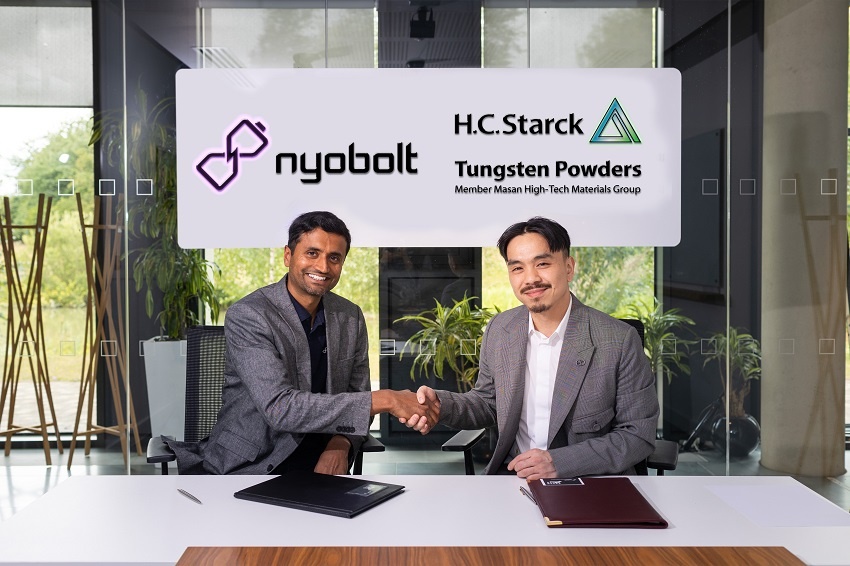

| Representatives of HCS and Nyobolt signing the strategic investment agreement |

The newly created Li-ion battery now offers super-fast charging, with users being able to charge up to 90% in only 5 minutes. This innovative battery solution offers long-term capacity retention with 10 times greater durability, strong energy density, 10 times greater capacity, and higher heat resistance.

Compared to other Li-ion batteries, Nyobolt's battery anode technology offers stronger performance thanks to a specially made Niobium and Tungsten coating. The two companies are currently working to commercialise their products ready for launch soon.

Dr. Sai Shivareddy, CEO and co-founder of Nyobolt said, “Fast charging remains a critical unmet need as the world electrifies with more sustainable forms of energy. We are excited about the partnership with H.C. Starck and see it as a stepping stone to increase our scale and speed to market and revealing the true potential of Nyobolt technologies.”

|

| Advanced tungsten recycling technology at HCS |

A significant stride in promoting the circular economy and realising global ESG strategy

Li-ion battery products promise to foster the development of the circular economy based on HCS’ outstanding recycling capabilities, including the advanced environment-friendly black waste recycling technology. This helps ensure a sustainable supply chain of Tungsten as a raw material that is critical to the high-tech materials industry.

CEO of Masan High-Tech Materials Craig Bradshaw shared, “If you look at your mobile phone, the battery will wear out and continue to degrade. After three years of use, although the phone is still working, it needs to be replaced because the battery is no longer good. Our research on the use of tungsten in battery production shows very positive results. The battery will not degrade over time, it will last much longer, and as a result, there will be less waste in the world.”

The cooperation between HCS and Nyobolt in battery technology is anticipated to help promote both companies' environmental, social, and governance (ESG) strategies.

“Our goal is looking to do better and innovating more while complying with the law and minimising the impact on the environment,” added Bradshaw.

|

| Development and research activities at H.C. Starck |

The outstanding applications of HCS-Nyobolt Li-ion batteries promise to bring unique experiences for customers in key industries such as electric vehicles, automation and robotics, consumer electronics, cordless tools, stationary power storage, and portable fast chargers.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- Masan Consumer names new deputy CEO to drive foods and beverages growth (February 23, 2026 | 20:52)

- Myriad risks ahead, but ones Vietnam can confront (February 20, 2026 | 15:02)

- Vietnam making the leap into AI and semiconductors (February 20, 2026 | 09:37)

- Funding must be activated for semiconductor success (February 20, 2026 | 09:20)

- Resilience as new benchmark for smarter infrastructure (February 19, 2026 | 20:35)

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

- Strengthening the core role of industry and trade (February 19, 2026 | 08:35)

- Future orientations for healthcare improvements (February 19, 2026 | 08:29)

- Infrastructure orientations suitable for a new chapter (February 19, 2026 | 08:15)

Mobile Version

Mobile Version