Vietnam masters core technologies of automobile value chain

|

A pivotal shift from assembly to mastering core stages

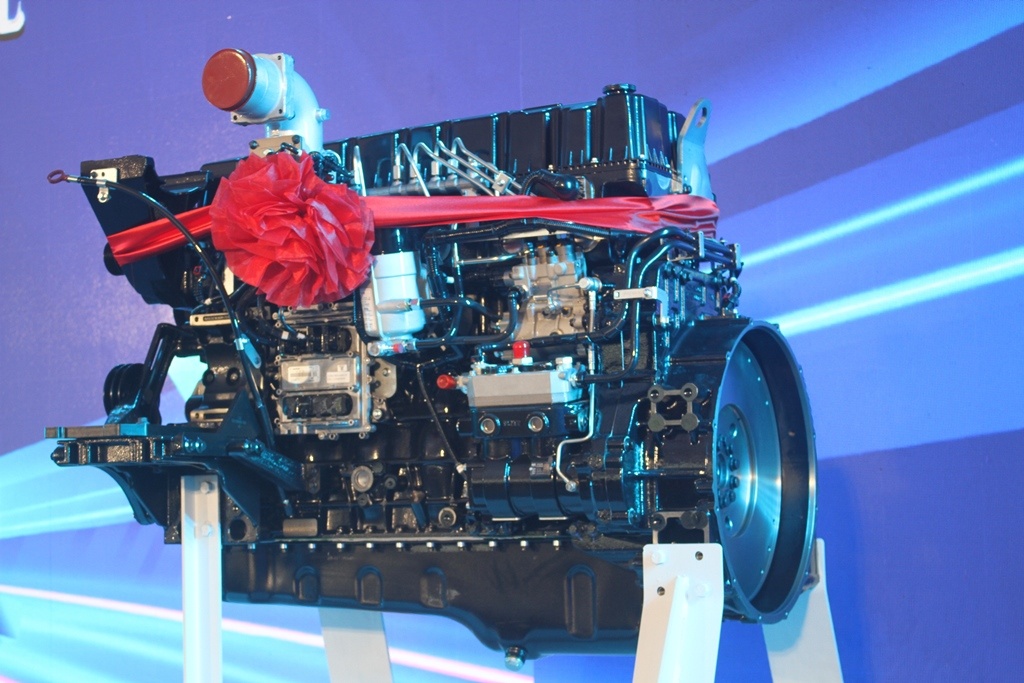

For years, Vietnam’s automobile industry has depended heavily on imported components, especially engines – the most complex and value-defining part of any vehicle.

With the Kim Long Engine Manufacturing and Assembly Plant project now operational, equipped with over 90 per cent automation and full data traceability, Vietnam is witnessing an important shift. The country is finally moving closer to the core of the automobile value chain.

The localisation rate will increase as the engine block, crankshaft, cylinder head, and other core components are produced domestically.

It lays the foundation for reducing trade deficits, increasing export value, and developing the precision engineering sector – a key pillar of modern industrialisation.

Chan May – Lang Co: from favourable location to new growth pole

The plant is strategically located within the Chan May-Lang Co Economic Zone – a gateway region with a deepwater port on the North-South corridor. This is a starting point for a mechanical and automobile industrial cluster. The plant will draw precision engineering enterprises, casting, forging, and machining businesses, research and development and quality inspection centres, industrial logistics systems, a network of vocational and engineering training centres, and a new industrial urban area.

The venture is expected to create a new industrial growth pole in the central region. This presents an opportunity for the region’s economy to address the imbalance between services and production, while climbing the manufacturing value chain.

|

Vietnam stands before an opportunity to elevate its position in ASEAN

In ASEAN, the automobile industry has long been clearly divided. Thailand is dubbed the "Detroit of Asia", while Indonesia excels in its market size and mass assembly. Malaysia focuses on building its national brand. Despite being decades behind, Vietnam is now facing a rare opportunity to climb the value ladder.

Amidst the strategic shift of global supply chains, multinational corporations have actively diversified production operations and supply chains, especially in the fields of mechanical engineering, manufacturing, semiconductors, automobiles, and electronics.

In this context, Vietnam boasts three strategic advantages:

-

A central position in ASEAN with high stability, making it easy for international businesses to access both the Northern supply chain (China, South Korea, Japan) and the southern supply chain (Thailand, Indonesia).

-

Rising industrial capacity, especially as Vietnam has successfully attracted large-scale ventures in electronics, batteries, materials, and precision engineering.

-

Deep integration policies, with a global network of free trade agreements (FTAs), creating a superior advantage in tariffs over regional peers.

Against this backdrop, Vietnam has produced automobile engines for the first time, marking a technical step forward. The move also sends a strategic message to the regional market. Vietnam is ready to take on more complex, higher-value stages in the automobile value chain. If guided by smart industrial policies, Kim Long Engine Manufacturing and Assembly Plant can play three strategic roles.

First, the facility can become a technology launchpad for Vietnam to deeply penetrate the supply chains of Thailand and Indonesia, which are looking to diversify their sources of components and engines in the region.

Second, the initiative is expected to create a new competitive edge for Vietnam. Thus, the country can draw not only assembly companies, but also core component manufacturers, from moulds and casting and forging to sensors and control chips.

Thirdly, it is essential to create conditions for the development of Vietnam's design-manufacturing capacity, a prerequisite for transitioning from a "participant" to a "trendsetter" in ASEAN’s automobile industry.

For the first time, Vietnam has the opportunity to switch from a follower to a key player in the region’s automobile production and supply chain. To unlock these opportunities, Vietnam needs to issue bold policies and a far-reaching vision to transform a factory into a platform to gain the national competitive edge.

Identifying challenges to not miss the opportunities

To harness the power of the new engine plant, it is vital to identify both opportunities and challenges.

One of the first challenges is the localisation rate. Vietnam has made great strides when stepping into engine production. However, to spread values strongly, Vietnam needs to ensure that the localisation rate is more substantive. The transfer of modern technologies, the strengthening of domestic business capabilities, and the gradual mastery of core components will ultimately determine long-term success.

Another challenge arises from the trend of green technology. The global automobile industry is rapidly transitioning to electric vehicles, hybrids, and clean powertrain solutions. This not only opens up opportunities but also presents a strategic requirement for Vietnam. The country must both develop traditional engines to serve existing needs while proactively preparing for the next-generation technologies to avoid being out of sync in the future.

Supporting industries are one of the challenges. A modern engine factory can create a significant spillover effect. To further raise efficiency, it needs a strong ecosystem of supporting industry enterprises. Upgrading domestic mechanical, casting, forging, material, and component manufacturers is essential to building a sustainable homegrown value chain.

Last but not least, there is the challenge of a highly skilled technical workforce. The engine industry requires a team of highly skilled engineers, technicians, and workers. This presents both pressure and opportunity for universities and vocational training institutions to work more closely with businesses, developing training models that are directly connected to real production needs.

|

From industrial milestone to national launchpad

For the establishment of the engine plant to be more than just a symbolic milestone but truly become a driving force for elevating Vietnam's industrial sector, a synchronous policy response system with a long-term vision and effective implementation is needed. It is the time for Vietnam to shift from receiving technology to "building national industrial capacity.

First, the key to increasing value is to ensure substantive localisation. Indeed, localisation is not just the percentage of domestically produced components, but the ability to master technology and create domestic added value. To achieve this, policy needs to establish a technology transfer roadmap in a compulsory and measurable manner. The development of laboratories and R&D centres between businesses, universities, and research institutes will improve design-testing capabilities. The localisation rate should be independently evaluated based on economic value and technology content.

Second, it is vital to form a supporting industry ecosystem surrounding Chan May – Lang Co. An engine factory can only unlock its strength when surrounded by a strong ecosystem of supporting enterprises. Therefore, there should be tax, land, and credit incentives to attract mechanical, material, and mould enterprises to establish factories in the area. This is coupled with a mechanism for industrial supply-demand connection. Thus, Vietnamese businesses have the opportunity to participate in the supply chains of Kim Long and regional car manufacturers.

If this ecosystem becomes a reality, Chan May – Lang Co can become a regional-scale automobile and mechanical engineering industrial cluster, creating a spillover effect across the central region.

Third, heavy investments in technical human resources are the decisive factor. No industry can develop without a team of highly skilled engineers and technicians. Training needs to be substantive. Some measures include expanding the "learn-work” dual training model, linking training with production lines, and establishing a Central Manufacturing Technology Centre to serve the needs for skill upgrades and R&D. Scholarships and preferential credit also help attract students to mechanical engineering, automation, and material technology.

Fourth is regional planning with a 20-30 year vision or even further. A large-scale engine factory requires compatible industrial-logistics-urban infrastructure. Therefore, it is necessary to develop the Chan May seaport, railway, road, and warehousing infrastructure synchronously to reduce logistics costs. A green and smart industrial urban area should be developed for experts and high-skilled workers, creating an attractive and sustainable living environment. Comprehensive regional planning will turn Chan May – Lang Co into a new industrial destination for the ASEAN region.

Fifth, it is vital to prepare early for the green technology future. The global trend is rapidly shifting towards new powertrain technologies. Vietnam should establish national standards and regulations for the green automobile industry, creating a legal environment for businesses with innovative technologies.

Kim Long Motor Hue Industrial Cluster has ramped up technology transfer and investments in the research and testing of hybrid engines, electric motors, fuel cells, and clean energy solutions.

If Vietnam capitalises well on the opportunity from Kim Long Engine Manufacturing and Assembly Plant to develop the supporting ecosystem, train human resources, upgrade technology, and formulate proper regional planning, the inauguration event may go down in history.

It marks the beginning of a new chapter where Vietnam steps up to a higher position in the global value chain, with a strong, confident, and future-oriented mechanical industry that is green, clean, and sustainable.

| $113 million auto assembly and manufacturing complex licensed The representative of Thua Thien-Hue People’s Committee has handed over the decision providing in-principle approval to Bach Viet Automobile Manufacturing Industry JSC to develop an automobile assembly and manufacturing complex in the province. |

| Kim Long Motors breaks ground on $260 million factory Vietnam's Kim Long Motors Hue JSC and China's Yuchai JSC started construction of a motor engine manufacturing and assembly plant in the central province of Thua Thien-Hue on August 23, with an investment of around $260 million. |

| Kim Long deal marks turning point for Vietnam’s auto industry Kim Long Motor has taken a major step in its regional expansion, securing a landmark export deal that strengthens the presence of Vietnamese-made vehicles abroad. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- SK Innovation-led consortium wins $2.3 billion LNG project in Nghe An (February 25, 2026 | 07:56)

- THACO opens $70 million manufacturing complex in Danang (February 25, 2026 | 07:54)

- Phu Quoc International Airport expansion approved to meet rising demand (February 24, 2026 | 10:00)

- Bac Giang International Logistics Centre faces land clearance barrier (February 24, 2026 | 08:00)

- Bright prospects abound in European investment (February 19, 2026 | 20:27)

- Internal strengths attest to commitment to progress (February 19, 2026 | 20:13)

- Vietnam, New Zealand seek level-up in ties (February 19, 2026 | 18:06)

- Untapped potential in relations with Indonesia (February 19, 2026 | 17:56)

- German strengths match Vietnamese aspirations (February 19, 2026 | 17:40)

- Kim Long Motor and AOJ Suzhou enter strategic partnership (February 16, 2026 | 13:27)

Mobile Version

Mobile Version