Stämm's Continuous Bioreactor Increases Antibody Productivity by up to 30x in European and American Pilots

SAN FRANCISCO, Jan. 15, 2025 /PRNewswire/ -- Stämm unveiled breakthrough results of its continuous bioreactor for monoclonal antibody production with pilot studies in Germany, Switzerland, and Argentina. It achieved a minimum of 15x greater volumetric productivity, projecting up to 50x during 2025. It also consistently evidenced up to 4x cellular density and specific productivity. The Bioprocessor, a plug-and-play desktop unit, cuts costs compared to traditional fed-batch systems and eliminates downtime while maintaining quality, working with both adherent and suspension cultures.

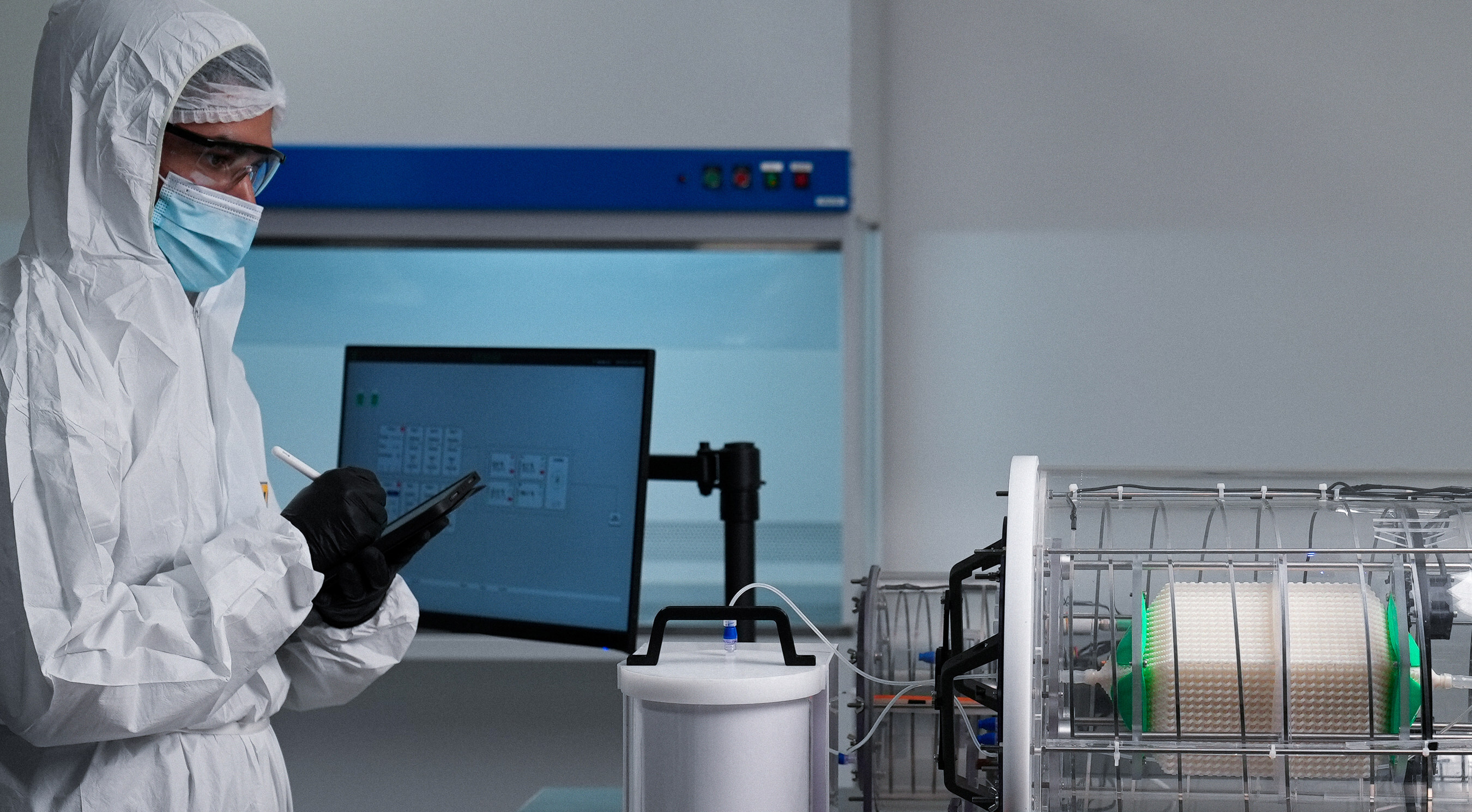

Stämm’s bubble-free continuous laminar flow bioreactor: the Bioprocessor.

As healthcare faces an increasing demand for therapies, Stämm enables the commercialization of biosimilars and different biologics for chronic and complex diseases such as oncology, inflammation, and immunology-related diseases. The biomanufacturing process for cell and gene therapies also benefits thanks to a high surface to volume ratio, low shear stress, and automation capabilities.

Stämm's closed-system design leverages single-use 3D-printed cartridges for seamless scalability and cost efficiency. With successful pilot implementations completed in under three months, the bioreactor is primed for global deployment and underserved markets. Its enhanced productivity stems from a homogeneous, stress-free environment that ensures consistent optimal conditions, including high gas exchange.

As the industry approaches a patent cliff, Stämm positions itself as an ideal partner in facilitating accessible and scalable biomanufacturing solutions. With early adopter partnerships underway, Stämm's approach is set to redefine biomanufacturing standards and enable next-generation medicines, fostering innovation in biologics production worldwide.

For more information, please visit Stämm's website at https://www.stamm.bio/

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- China Daily launches Dunhuang platform for international travelers (February 14, 2026 | 20:28)

- HanchorBio receives FDA orphan drug status for gastric cancer therapy (February 14, 2026 | 20:26)

- Tsukuba research park draws attention at SEMICON Japan 2025 (February 14, 2026 | 20:24)

- Omics Empower Hong Kong launches Xenium spatial transcriptomics services (February 14, 2026 | 20:22)

- Jemmia Diamond hosts Vietnam-UAE trade dialogue with ambassador (February 14, 2026 | 20:19)

- Wynn Resorts Macau wins most Forbes awards among Macao properties (February 14, 2026 | 20:16)

- Hotel seven x seven Itoshima set for April 2026 relaunch (February 14, 2026 | 20:13)

- Beko announces CEO transition, maintains sustainability focus (February 14, 2026 | 20:10)

- Global technology leaders launch Trusted Tech Alliance (February 14, 2026 | 20:07)

Tag:

Tag:

Mobile Version

Mobile Version