Maximising advantages of the circular economy

|

|

| Le Thanh Thao |

Li Yong, director general of the United Nations Industrial Development Organization (UNIDO), recently said at the 2018 World Manufacturing Forum in Italy, “Industry has proven itself as an unrivalled eradicator of poverty throughout the ages, by raising incomes, creating added value, and enabling greater social mobility. No country has ever risen to developed country status without a strong industrial policy focus.”

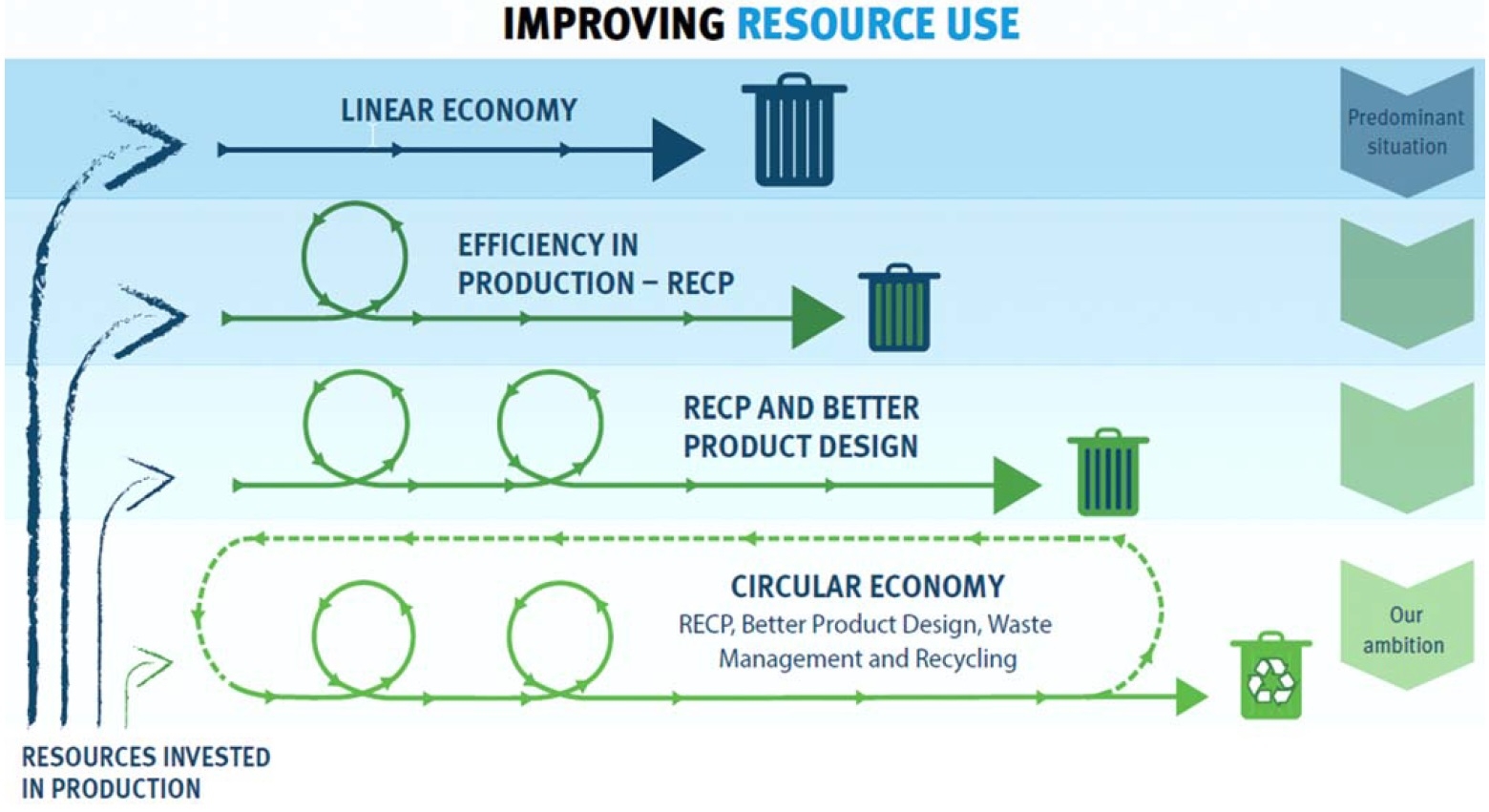

However, too often in the past industrial development has also been accompanied by environmental degradation and increased social inequalities. By and large, today’s manufacturing takes raw materials from the environment and transforms them into new products, which are then disposed into the environment after use. Eventually, limited raw materials run out and waste accumulates, either incurring expenses related to disposal or else polluting.

For more than 50 years, UNIDO has worked towards a truly sustainable industry. In doing so, UNIDO has moved towards a circular economy, in which resources are used over and over thanks to innovative business practices. In a circular economy, products are designed for durability, reuse, and recyclability, and materials for new products derive from old products. As often as possible, everything is reused, remanufactured, recycled back into a raw material, used as a source of energy, or as a last resort, disposed of.

The circular economy is directly linked to inventions such as green chemistry, eco-industrial parks, industrial symbiosis, and resource efficiency, clean production, and sustainable cities.

A key part of the circular economy is improving resource efficiency during production. To achieve this goal, UNIDO and the United Nations Environment Programme (UNEP) support the establishment and efficient operation of a global network with regional chapters. These chapters facilitate the effective transfer of Resource Efficiency and Cleaner Production (RECP) knowledge and technology, and foster both South-South and North-South co-operation. Alongside over 70 members of this network, Vietnam Cleaner Production Centre, established in 1998, has played a focal role in disseminating the “Cleaner Production” concept. It promotes adoption of the concept into various industries in Vietnam, ranging from chemicals, garments, and metallurgy to handicrafts, rice, and coffee. Services include applied preventive environmental strategies to processes and products to increase efficiency as well as reduce risks to both humans and the environment.

In other cases, UNIDO is extending resource efficiency beyond the borders of one company to groups of industries. A prime example of such approaches is the establishment of eco-industrial parks. Companies wanting to go beyond compliance in their environmental performance find the means to do so, not only by sharing environmental services and receiving targeted RECP advice, but also by taking advantage of each other’s by-products, such as heat, water, and recycled materials. Eco-industrial parks could make important contributions in the move towards the circular economy, both in industrialised and developing countries.

In Vietnam, the project “Implementation of eco-industrial park initiative for sustainable industrial zones in Vietnam” aims to transform existing industrial zones in the country into eco-industrial parks (EIPs), in which companies co-operate with the local community and each other to reduce environmental impacts and production costs. In addition, clean and low-carbon technologies and practices will be demonstrated within the industries to minimise greenhouse gas (GHG) emissions, the release of persistent organic pollutants, and land-based water pollution. Funded by the Global Environment Facility (GEF) and the Swiss State Secretariat for Economic Affairs (SECO), the project has been implemented by the Ministry of Planning and Investment in coordination with UNIDO in industrial zones in Ninh Binh, Danang, and Can Tho.

Under the support of EIPs project, Decree No.82/2018/ND-CP on the economic zones, industrial zones and processing zones with three specific chapters on EIPs was approved by the government this past May. The decree has for the first time ever conceptualised EIP and industrial symbiosis terms and defined contents related to the development of EIPs in Vietnam. The new decree will lay out strong legal foundations for up-scaling the EIP model to other industrial zones across the country.

Circular economy practices also result in significant energy savings by optimising energy systems, developing international energy management standards and bringing sustainable energy solutions to industries. Towards this approach, UNIDO co-ordinates with Vietnam’s Ministry of Industry and Trade to implement an industrial energy efficiency programme which aims to reduce energy consumption and GHG emissions through the promotion of the widespread adoption of energy-efficient boilers and best operating practices in industry. The project’s interventions facilitate the development of legal policy and legal frameworks to support the boiler standardisation system and raising awareness as well as training and capacity building for government agencies, boiler owners, operators, and manufacturers, and other stakeholders. The project also provides financial assistance for the implementation of energy efficient boiler adoption and manufacturing.

Moreover, UNIDO also promotes the use of renewable energy for productive use. The use of solar energy to run the cooling and lighting systems is an example. For the first time in Vietnam, the Excellence Centre for Harvesting, Pre-processing, Packing, Preservation and Transport of Mango in the Mekong River Delta uses green solar energy to run the cold storage system, ensuring about 40 per cent of the total power consumption, and some other electric equipment. This helps the company to reduce its operation costs. The centre was established under the project which aims to strengthen the supply capacity of the fruit and vegetable sector by applying proper technologies along the value chain. This is a UNIDO component in the joint UN programme to support the national target programme on new rural development in Vietnam.

The circular economy encourages inter-company exchanges and synergy-building, leading to better economic, social, and environmental performance. This in turn helps raise the overall performance of national economies and opens new markets and jobs.

On an international level, the circular economy facilitates the exchange of goods across borders by introducing standards to secondary raw materials that were previously considered waste. Improved product characteristics such as extended lifetime, recyclability, and serviceability further help to ensure that products can be used and sold on the global market. By helping overcome international trade barriers in this way, the circular economy offers new possibilities by which countries can prosper.

Countries, including Vietnam, today stand at a fork in the road. On the one hand, the pursuit of unsustainable, linear patterns of consumption and production threatens the well-being of future generations, while on the other hand, a restorative approach to increased prosperity is opening itself up to the world. Together with our global partners, and in service to our member states, UNIDO will continue to advance economic competitiveness, create shared prosperity and safeguard the environment in the world’s developing and transitional countries.

2018 is a special year for UNIDO as it marks the 40th anniversary of UNIDO’s technical co-operation with Vietnam. The past years have witnessed UNIDO sharing its international expertise and best practices to help Vietnam achieve inclusive and sustainable industrialisation. UNIDO has enjoyed very fruitful co-operation with national and provincial authorities; financing institutions; research institutions and academia; and business and professional associations, as well as the private sector.

With more than $100 million in grant expenditure, UNIDO’s technical co-operation activities have been carried out across a broad range of fields – from supporting government institutions to developing traditional industry, and from promoting investment to strengthening productivity.

In the coming years, UNIDO commits to working closely with relevant ministries and stakeholders in Vietnam to support the country in its important industrial sectors, in technology transfer, and in human resources development for Industry 4.0 as well as in formulating Vietnam’s new industrialisation strategy. UNIDO is also committed to supporting Vietnam in implementing its socioeconomic development priorities, green growth strategy, and Agenda 2030 and Sustainable Development Goals.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- NAB Innovation Centre underscores Vietnam’s appeal for tech investment (January 30, 2026 | 11:16)

- Vietnam moves towards market-based fuel management with E10 rollout (January 30, 2026 | 11:10)

- Vietnam startup funding enters a period of capital reset (January 30, 2026 | 11:06)

- Vietnam strengthens public debt management with World Bank and IMF (January 30, 2026 | 11:00)

- PM inspects APEC 2027 project progress in An Giang province (January 29, 2026 | 09:00)

- Vietnam among the world’s top 15 trading nations (January 28, 2026 | 17:12)

- Vietnam accelerates preparations for arbitration centre linked to new financial hub (January 28, 2026 | 17:09)

- Vietnam's IPO market on recovery trajectory (January 28, 2026 | 17:04)

- Digital economy takes centre stage in Vietnam’s new growth model (January 28, 2026 | 11:43)

- EU Council president to visit Vietnam amid partnership upgrade (January 28, 2026 | 11:00)

Tag:

Tag:

Mobile Version

Mobile Version