GE announces first commercial operation of 9HA.02 technology in Malaysia

|

| Track 4A Power Plant runs with the newest GE combined-cycle gas power plant |

The plant was safely constructed with the Taiwanese EPC partner, CTCI, and consists of two generating blocks, each equipped with the highly efficient gas turbine, a steam turbine, a generator, and a Heat Recovery Steam Generator (HRSG) from GE. In addition, under the terms of a 21-year agreement, GE will provide services and digital solutions to improve asset visibility, reliability, and availability of the Track 4A plant – which will produce the equivalent electricity needed to power approximately three million homes in Malaysia.

“We have a longstanding relationship with GE and we trust its HA technology will help us meet the increasing power demand and contribute to long-term energy security needs in Malaysia,” said Dato’ Haji Nor Azman bin Mufti, chairman of SPG. “We are proud to see how GE has adapted with hard work and efficiency to achieve the start of their first ever commercial operation for the 9HA.02 gas turbines despite the COVID-19 pandemic without compromising on health and safety.”

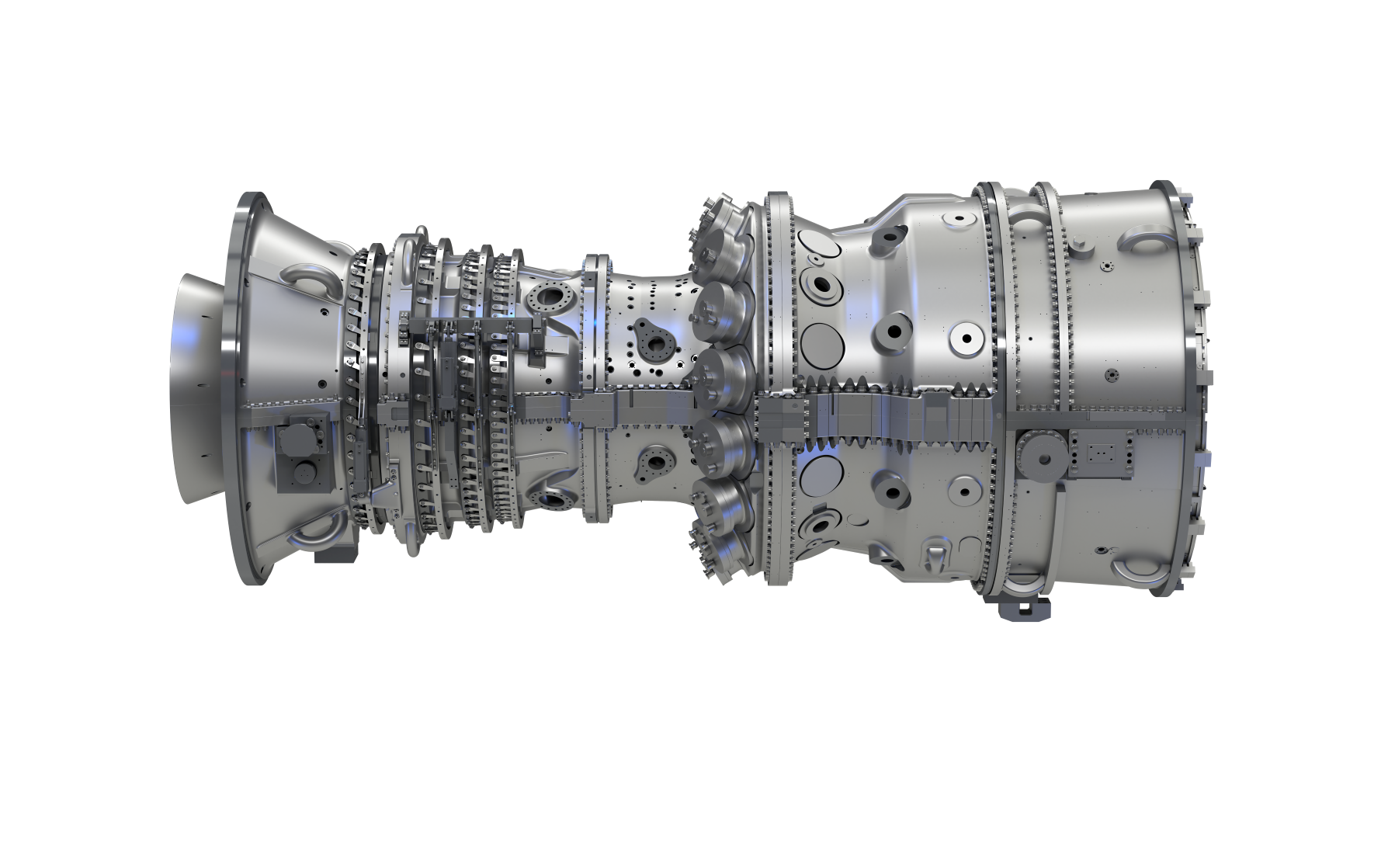

The plant features two single-shaft generating blocks, each equipped with a 9HA.02 gas turbine and a STF-D650 steam turbine, driving a W88 generator, and, for the first time installed in an H-Class Plant, a GE Once Through HRSG delivering higher combined cycle efficiency. The plant is controlled by GE’s Mark VIe integrated Plant Control System. Equipped with a single Operator Interface and common troubleshooting tools, plant personnel can operate the plant more efficiently and, when issues do arise, rapidly recover to improve overall plant availability.

|

| GE 9HA.02 turbine, the most advanced combined-cycle gas power generation unit in the industry |

GE will provide a full spectrum of digital solutions and plant improvement services, major inspections of the 9HA.02 gas turbines, along with technical advisory services. Overall plant performance will be monitored and enhanced with GE Digital’s Predix Asset Performance Management software to help improve asset visibility, reliability, and availability while reducing operating and maintenance costs. In addition, data collected from sensors throughout the facility will be monitored and analysed 24/7 at GE’s Monitoring & Diagnostics Center in Kuala Lumpur.

“With more than 40 years of operation and the largest base of installed gas turbines in the country, GE is uniquely qualified to help meet the growing power demand in Malaysia,” said Ramesh Singaram, president and CEO of GE Gas Power in Asia. “Today marks a tremendous milestone for our HA fleet, as we celebrate the world’s first commercial operation of our flagship turbine here in Malaysia. We look forward to helping Southern Power Generation reap the benefits of our latest technology as well as combined services and digital solutions, helping to deliver more reliable and flexible power generation for the country.”

“By drawing on our rich experience in global power plant EPCs, CTCI and GE have proudly achieved more than 10 million safe man-hours on this project, a testament to the team’s reliability. The two companies’ joint success also paved way to another recent partnership in late 2020, helping us win a multi-billion-dollar EPC contract for five combined cycle gas power units in Taiwan,” said Michael Yang, chairman of CTCI Corporation.

GE’s HA gas turbines are the world’s largest and the most efficient gas turbines with more than 100 units ordered by more than 48 customers across 20 countries. GE’s second-generation H-class fleet has accumulated more than 850,000 (as of January 2021) operating hours of commercial experience. To further decrease carbon emissions utilising gas power, GE’s H-Class gas turbine portfolio currently has the capability to burn up to 50 per cent by volume of hydrogen when blended with natural gas.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Addressing Vietnam's energy challenges with aeroderivative gas turbines (February 28, 2023 | 09:33)

- How to sprint ahead in 2023’s worldwide energy priorities (February 08, 2023 | 13:55)

- Boosting Vietnam's grid stability through gas turbine technology (November 22, 2022 | 20:02)

- Healthcare trio collaborates to provide thousands of free breast scans (October 27, 2022 | 17:19)

- GE Healthcare's vision for AI-backed radiology (September 29, 2022 | 11:53)

- GE brand trio to shape the future of key industries (July 19, 2022 | 15:35)

- GE unveiling brand names and defining future (July 19, 2022 | 15:16)

- GE: the shortest route towards sustainability (July 18, 2022 | 08:00)

- Be proactive in an uncertain world (May 20, 2022 | 11:40)

- GE secures first 9HA combined cycle power plant order in Vietnam (May 16, 2022 | 17:06)

Tag:

Tag:

Mobile Version

Mobile Version