ABB powers Industry 4.0 for sustainable growth

ABB Vietnam’s director Brian Hull spoke to VIR’s Phuong Thu about his company’s 25-year success story in the country as well as the path Vietnam should take to ensure sustainable growth.

ABB has been a part of Vietnam’s economic development since 1993. Would you like to tell us about your performance in Vietnam?

|

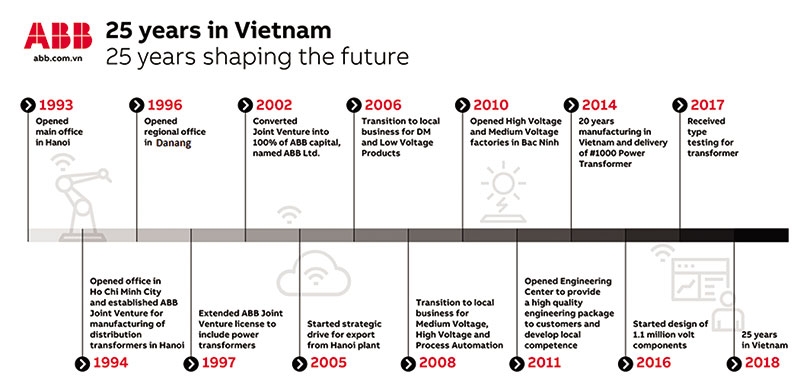

ABB entered Vietnam early and this year is an important milestone for us, as it marks our 25th anniversary. Over the last 25 years, ABB Vietnam has grown to become a reliable partner in the field of technology, providing solutions and services to the market. In addition, ABB factories in Vietnam manufacture transformers, high-voltage components, and medium-voltage power products for customers across Southeast Asia and the world. We currently employ some 900 people across Hanoi, Danang, and Ho Chi Minh City.

Despite the financial crisis in 1997, which impacted the global economy with long-lasting consequences, ABB in Vietnam stayed strong, believing in the potential of the Vietnamese market. We have shown our long-term commitment to the Vietnamese market with the strategic drive for exports from the Hanoi factory in 2005 and continued investment in expanding our footprint with the completion of the Bac Ninh High Voltage and Medium Voltage factories in 2010. Our world-class transformer factory in Vietnam exports across the Asia Pacific region, serving clients from Australia, New Zealand, and Japan and reaching out to countries in the Middle East and southern Africa.

ABB Vietnam is proud to have contributed to the delivery of many key projects that have an important role to play in Vietnam’s development. Our flagship projects include the Phu My thermal power plant, the Hai Van tunnel, the Uong Bi thermal power plant, the Dung Quat refinery, the Tri An hydro power plant, Nui Phao Mining, Song Gianh Cement Plant, HCMC Water Distribution, and many substations for the national grid. ABB Vietnam also powered and automated many industrial plants in different economic sectors.

These significant projects are evidence of our success in the Vietnamese market and have been made possible thanks to our competent team of professional sales, service, and design engineers.

|

| ABB’s Industry 4.0 solutions are implemented, to great success, in the company’s own factories |

During your 25 years in Vietnam, how has ABB shown its commitment to Vietnam’s green business?

We incorporate environmental criteria into all major business decisions and make a commitment to environmental principles in our business operations. ABB Vietnam is proud to be contributing to sustainable development in its own factories in Vietnam and thus showing how technology can secure a long-term profitable future. This business sector’s growth leads to employment opportunities, while at the same time

fostering an environmentally sound and socially responsible economic trajectory for the future growth of the company.

For instance, we produce ‘green’ transformers in Vietnam that help to reduce energy losses with their technical

design features. In these transformers, we use the environmentally friendly insulation fluid FR3, which is natural ester oil made from soya bean with high biodegradability.

ABB uses low-volatile organic compounds (VOC) paint in our production. VOCs are unstable, carbon-containing compounds, which cause air pollution and a host of health issues, and our use of low VOC minimises the impact on the environment and our staff. The process controls which are supplied by ABB for cement and steel factories make these energy-intensive industries more efficient and optimise productivity.

Our determination to strive for sustainable development has also been shown in our effort to recycle the majority of waste from factories and offices. ABB in Vietnam has automated processes and machines in factories to reduce energy use and is continuing to find ways to reduce energy consumption.

With the participation in as well as hosting of conferences and exhibitions, ABB in Vietnam has made an active contribution to public debate, making policy recommendations and initiatives to simplify the access of business to the government, ministries, and the authorities when it comes to efficient and sustainable energy consumption, showing the long-term commitment to green operations and sustainable development.

ABB also offers systems and solutions to enable renewable power production, foster sustainable public transport, and develop smart cities. We are here to help drive Vietnam’s long-term success in these sectors with a proven track record, and using expertise both globally and in Southeast Asia in particular.

|

| The world's first digital transformer launched by ABB |

What are the areas ABB Vietnam focuses on to maximise the market’s potential?

ABB sees a range of opportunities in this rapidly emerging economy, specifically to offer solutions to make project implementation easier and to digitalise industries and the infrastructure sector. This is backed by our years of experience and domain expertise in helping ensure grid reliability and developing renewable power resources. Nevertheless, whether it is the growing power and infrastructure needs or the rapidly developing manufacturing base, with our products, services, and digital offerings, we can make a truly exciting contribution here.

We focus on three main areas. The first one are the key utilities electricity and water. We see a lot of growth here and we supply the latest technology to manage and ensure high reliability in the grid. In addition, we are interested in the area of renewable power generation. As for water, quality and leakage is now a major problem in the cities. For instance, we help our customer Saigon Water Supply Corporation to increase efficiency, reduce water leakage, prevent disruptions, and ensure everyone has access to clean water in Ho Chi Minh City.

Secondly, we work with a range of industrial customers, including food and beverages (F&B). Our expertise in automation, power management, and robotics allows our F&B clients to serve their customers with higher quality and speed. The last area is infrastructure and transportation. ABB helps to support the country’s development in sustainable urbanisation by supplying smart technologies, for example in hotels, conference centres, and data centres. We are also excited by the potential to deploy new sustainable transport solutions, including charging solutions for electric vehicles.

|

Could you tell us about the next step in your strategy for Vietnam?

Continuing a more than 130-year history of innovation, ABB today is writing the future of industrial digitalisation and driving the Fourth Industrial Revolution.

In line with ABB Group, our digital-first portfolio for customers in utilities, industry, and transport and infrastructure is based on two clear value propositions: bringing electricity from any power plant to any plug, and automating industries from natural resources to finished products.

ABB is well positioned to tap into the significant opportunities in Vietnam to deliver long-term profitable growth with its strong market presence, broad business scope, technology leadership, and financial strength.

How can Vietnam make the most out of the opportunities brought about by Industry 4.0? Could you highlight your products and services to leverage this trend?

Industry 4.0 aims to facilitate the interaction between information technology and operation technology by providing information at all levels. It allows users to maximise efficiency and increase transparency, traceability, and visibility.

As we know, Vietnam’s economy and industrial base are growing quickly. Manufacturers can use the power of this revolution not only to secure new customers, but also to tune their processes in order to deliver higher efficiency and cost effectiveness.

As Vietnam moves up the global supply chain, demand for quality and traceability of products is increasing. We see various industrial customers – from power generation to mining and cement – asking for our help in delivering real benefits by using data analytics and collaboration tools to utilise the hidden potential.

In our own factories, we have installed manufacturing execution systems to provide real-time information on the manufacturing process. At our high-voltage component factory in Bac Ninh that came into operation in 2010, we trace the sources of materials of all products through these systems. We also use ABB smart sensors to monitor the performance of our robot motors and send alerts if key parameters such as temperature or vibration cross certain thresholds. The on-site waste water plant is monitored and controlled, and all the information is available in the cloud to allow optimisation and remote monitoring. In addition, the ABB pilot solar plant will come online in June and will be monitored through Internet of Things technology, making the data readily available. These examples demonstrate ABB’s strong commitment to delivering Industry 4.0 solutions.

ABB’s solutions for Industry 4.0 are delivered within our ABB Ability platform. ABB Ability is our unified, cross-industry digital offering with devices, systems, solutions, services, and a platform that enable our customers to know more, do more, and do it better.

There are many more products and services to highlight, but foremost among them is the deployment of robots in a variety of industries such as electronics, automotive, and F&B. Remote inspectors can monitor their performance and suggest modifications or software updates to improve it.

Optimising the performance, reliability, and return on investment of renewable energy is also a key topic and we are working with several customers to ensure we can deliver solutions for solar power development projects. In the near future, we will organise a workshop with the Ministry of Industry and Trade to explore how Industry 4.0 solutions can help manage the impact of renewables on Vietnam’s power grid.

How has ABB shown its commitment to its social responsibilities as a global company, such as supporting the communities in which it does business and leaving behind an intact environment for future generations?

ABB Vietnam is proud to be contributing to sustainable development in its own factories in Vietnam and thus showing how technology can secure a long-term profitable future. This business sector’s growth leads to employment opportunities, while at the same time fostering an environmentally sound and socially responsible economic trajectory for the future growth of the company. The commitment to sustainable corporate management has a long tradition at ABB and has informed a wide range of activities with relevance to society for years.

For instance, we supported the renovation of the Hoa Binh Children’s Village. We also organised ABB Social Days along with patient support programmes at the National Institute for Blood Transfusion and the Vietnam National Hospital for Pediatrics in recent years.

To further develop the next generation of engineering professionals, we donated advanced technologies and products to the learning environment in leading universities across Vietnam. With the ABB Jürgen Dormann Foundation scholarship programme, ABB has supported talented students with limited financial resources in pursuing engineering education until graduation since 2010. Our Graduate Engineering Programme aims to provide opportunities to excellent engineering graduates to work in different units within ABB Vietnam and throughout Southeast Asia.

We are very proud that ABB has been named a “Future Ready Enterprise” and is one of the employers that Vietnamese people want to work for the most.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- NAB Innovation Centre underscores Vietnam’s appeal for tech investment (January 30, 2026 | 11:16)

- Vietnam moves towards market-based fuel management with E10 rollout (January 30, 2026 | 11:10)

- Vietnam startup funding enters a period of capital reset (January 30, 2026 | 11:06)

- Vietnam strengthens public debt management with World Bank and IMF (January 30, 2026 | 11:00)

- PM inspects APEC 2027 project progress in An Giang province (January 29, 2026 | 09:00)

- Vietnam among the world’s top 15 trading nations (January 28, 2026 | 17:12)

- Vietnam accelerates preparations for arbitration centre linked to new financial hub (January 28, 2026 | 17:09)

- Vietnam's IPO market on recovery trajectory (January 28, 2026 | 17:04)

- Digital economy takes centre stage in Vietnam’s new growth model (January 28, 2026 | 11:43)

- EU Council president to visit Vietnam amid partnership upgrade (January 28, 2026 | 11:00)

Mobile Version

Mobile Version