Giants lead green packaging future

|

| Giants lead green packaging future, illustration photo/ Source: freepik.com |

About 450 businesses from more than 30 countries and territories will gather for the 16th edition of ProPak in Ho Chi Minh City in November to establish a panorama of equipment and new technology in future food processing and packaging.

The exhibition will offer a dynamic business platform that is shaping the future of the processing and packaging industries, particularly in an industry closely impacting the environment like packaging.

Food packaging currently accounts for 30-50 per cent of the total packaging industry space, according to statistics from the Ministry of Industry and Trade, leading to a strong symbiotic relationship between the two fields of food and packaging.

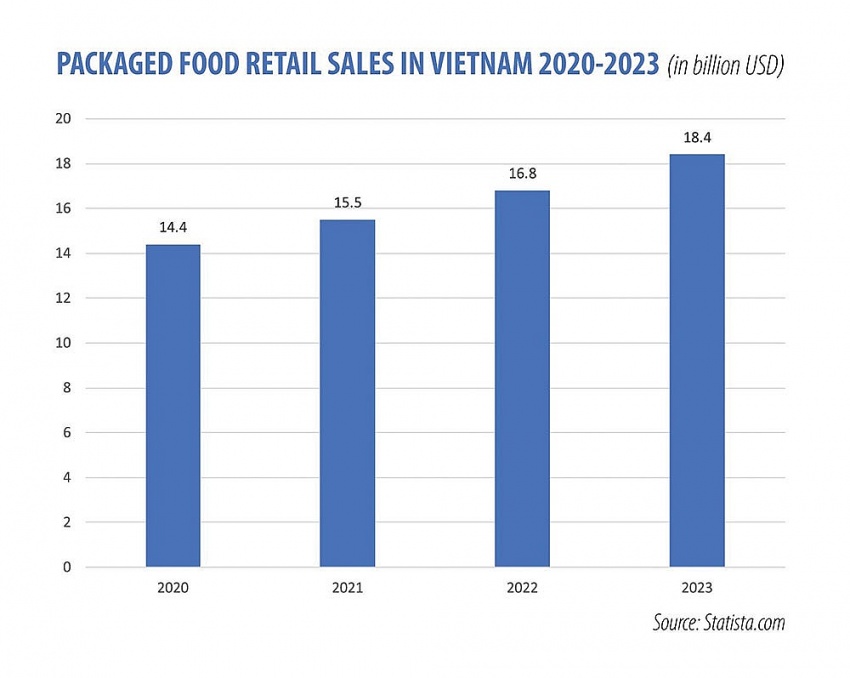

According to German data provider Statista, the packaging sector has been growing on-year with an average rate of 15-20 per cent, in parallel with the average increase of about 10 per cent of the food and beverages market over the next four years. Statista predicts that the retail sales of packaged food is growing on-year in Vietnam, with it forecasted to grow to $18.4 billion in 2023 and become one of the fastest growing fields in Vietnam, attracting the participation of foreign business sector.

After the investment and expansion of many foreign food packaging manufacturing enterprises in recent years, such as Tetra Pak, SCG Packaging, Wing Fat Printing, Meiwa Pax, and St. Johns Vietnam, the Vietnamese market continues to record the appearance of new faces.

Packaging equipment multinational Sidel decided to move its headquarters from Thailand to Vietnam at the beginning of this year to take advantage of opportunities from a new market.

According to East and West Asia sales director Parkpoom Praprom, Sidel had a representative office in Vietnam before 2023. “But now, all main departments have been brought to Vietnam, and Sidel also recruited more Vietnamese staff for this transformation,” he said.

Last year, German waste management and recycling solutions provider ALBA Group Asia also signed a $50 million cooperation agreement with VietCycle partner in Vietnam to cooperate in developing a recycling plastic processing company with capacity of 48,000 tonnes a year.

The result of this joint venture is the appearance of the first largest recycled plastic factory in the north, expected to come into operation in 2024.

Changes in food packaging production receive active support from the production transformation process of food businesses for green and sustainable consumer needs from customers.

According to consulting company Nielsen, 86 per cent of Vietnamese consumers said they are willing to pay more for products with biological or recycled packaging. Meanwhile, the Law on Environmental Protection that took effect last year and regulates the payment of emission treatment fees, also creates a push for manufacturers to invest more in the transition to green and sustainable packaging.

The game continues to be led by foreign businesses with great potential and pioneering in environmental activities.

Le Thi Hong Nhi, head of Communications and Corporate Affairs at Unilever Vietnam, said, “The green transformation journey plays a nuclear role in moving towards sustainable development. We are committed to building a green value chain and have pioneered achieving net-zero emissions across the entire operating system since 2021.”

To date, Unilever has reduced by more than half the virgin plastic used in packaging. Nearly two-thirds of packaging is recyclable, while it has collected and processed more than 20,000 tonnes of plastic waste, improving social welfare conditions for more than 2,500 female workers in the informal collection workforce.

Meanwhile, design improvements to eliminate unnecessary packaging, lower the use of virgin plastic, and replace with environmentally friendly materials helped Nestlé Vietnam reduce nearly 2,500 tonnes of plastic packaging over the last two years. Khuat Quang Hung, head of Corporate Affairs of Nestlé Vietnam, said that about 94 per cent of Nestlé’s product packaging is designed to be recyclable and reusable. This business is also aiming to use single-layer packaging to help operate recycling in an easier manner.

“There is no sanction that forces the company to do so, but we recognise our responsibility and always want to be at the forefront of transformation activities,” Hung told VIR.

The process of switching from paper straws to plastic straws for the Milo brand has tripled Nestlé’s production costs, but reduced up to 700 tonnes of disposable plastic each year. Improving the packaging of Maggi soy sauce and bottle caps also contributes to a 10 per cent improvement in the weight of plastic used for one product, equivalent to 130 tonnes of plastic per year.

LaVie, a beverage brand belonging to Nestlé’s ecosystem, is also a pioneer in using PET recycled plastic. Currently, one bottle of LaVie uses 50 per cent recycled plastic.

“Recycling is just one step of the circular economy, the necessary condition is to have a collection system, technology and solutions suitable for all types of product packaging,” Hung added.

Nguyen Van Viet, chairman of the Vietnam Beer-Alcohol-Beverage Association, said that packaging technology is becoming an important challenge for the beverage industry because from 2024, manufacturers and importers will have to carry out extended producer responsibility according to the Law on Environmental Protection.

“Businesses that produce and use cans and bottles all lose recycling costs. We are proposing solutions to overcome difficulties for businesses, including supporting recycling costs, especially for domestic enterprises that are behind foreign enterprises in both capital source and production scale,” Viet said.

He admitted that while the country is doing a good job of recycling beverage cans, there are often issues when it comes to other types of packaging recycling. “The problem in Vietnam today is not what technology to apply, but how to recycle,” he said.

According to Praprom from Sidel, this business wants to provide standard, sustainable packaging products, and reduce the amount of waste through simple recycling,

“Glass packaging products take twice the time to be transported to the factory for washing and recycling. Canned products will not need to return to the factory but can be recycled directly at the collection point,” Praprom explained.

|

| Boon Teong Tee - General manager Informa Markets Vietnam

Over the past few years, the food and beverage packaging industry has benefited from the development of e-commerce and the rapid spread of app-based delivery business locally, and the free trade agreements that Vietnam has participated in. The effects of social distancing in 2020-2021 have created consumer habits which rapidly spread due to the convenience it offers and has expanded the use of fast-moving consumer goods (FMCG) packaging. To date, we do not see this trend diminishing and in fact, it has accelerated due to its convenience element, and at the cost of more FMCG waste to be managed in the cities. This recent phenomenon has disrupted businesses and provided new opportunities for others. It has also introduced pressing needs of resource conservation through circularity practices, as Vietnam will be challenged to handle rapid FMCG waste volume increases. The urbanisation of Vietnam represents the key underlying reason, with both positive and negative effects for the environment and economy. Packaging remains one of the fastest growing sectors in the Vietnamese market, with a growth rate of 13.4 per cent per year in the 2015-2020 period. New products and technologies are expected to sustain this longer-term growth rate for the years to come. I think many market leaders are working aggressively towards creating products which generate less waste through circularity concepts that offer bigger recycling opportunities with lesser costs and simpler processes through the development of new materials and design. To acknowledge the growing importance of the drink and beverage industry, Informa Vietnam has also recently announced the launch of a dedicated exhibition focusing on new technologies and services to support the expanding drink and beverage industry. This exhibition cluster is co-located with Propak Vietnam and it is our intention to grow this sector aggressively for the expanding market. Hoang Duc Vuong - Chairman Vietnam Recycled Plastics Association

The management of domestic waste in Vietnam in the past 40 years has not been properly cared for, with scrap taken to craft villages for recycling, causing pollution. For many years, waste has not been classified, leading to plastic scraps worth recycling being contaminated with unpleasant odors, and very difficult to clean. European deodorising technology will probably have to give up on waste in Vietnam if there is no waste classification. Most recyclers do not dare to use 100 per cent domestic scrap but mainly have to import scrap from abroad to ensure input. As for small recycling facilities in craft villages, the low quality of scrap is the very cause of poor quality recycled products, accompanied by secondary pollution. For businesses in this country, investment costs for recycling are very large, making competition with recycling craft villages more difficult. Classifying waste from beginning brings benefits that go beyond the development of the plastic recycling industry. Separating organic waste and recyclable waste from messy landfills is the first step to processing organic waste to make biofertiliser or animal feed and recycling less valuable waste such as nylon bags, cake shells, and candy shells. The benefits can be up to billions of dollars. I think that with the joint support of the community and international organisations, the recycling industry of Vietnam will also develop. It is because this is the path that must be taken if we want to build a circular economy, contribute to the circulation of waste, and save the cost of importing resources from abroad. |

| Packaging provider SIG reinforces sustainability commitment in Asia Through its 25 years of sustainability journey in Asia, Switzerland-headquartered aseptic packaging solutions provider Schweizerische Industrie Gesellschaft (SIG) has been making ambitious sustainability commitments. Angela Lu, president and general manager Asia Pacific South at SIGdiscussed with VIR’s Luu Huong how SIG facilitates the consumer’s need for convenience, and how sustainable packaging is becoming a key focus for sustainability. |

| ProPak Vietnam 2023 brings new solutions for the processing and packaging industry ProPak Vietnam 2023 is returning from November 8 to 10 at the Saigon Exhibition and Convention Center, promising to bring valuable trading opportunities for both domestic and foreign enterprises in the processing and packaging industries. |

| Vietnam inspires innovation with SCGP Packaging Speak Out 2023 SCGP Packaging Speak Out 2023 - Vietnam inspires Vietnamese young talents to elevate packaging’s role in business through their creativity. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Vietnam sets ambitious dairy growth targets (February 24, 2026 | 18:00)

- Masan Consumer names new deputy CEO to drive foods and beverages growth (February 23, 2026 | 20:52)

- Myriad risks ahead, but ones Vietnam can confront (February 20, 2026 | 15:02)

- Vietnam making the leap into AI and semiconductors (February 20, 2026 | 09:37)

- Funding must be activated for semiconductor success (February 20, 2026 | 09:20)

- Resilience as new benchmark for smarter infrastructure (February 19, 2026 | 20:35)

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

- Strengthening the core role of industry and trade (February 19, 2026 | 08:35)

- Future orientations for healthcare improvements (February 19, 2026 | 08:29)

Tag:

Tag:

Mobile Version

Mobile Version