Chinaplas 2018: green and efficient packaging

Functionally speaking, innovations in packaging are geared towards extending the shelf lives of products, reducing food waste, and improving product safety. However, the industry is still being challenged by rising raw material costs and pressure from environmental issues.

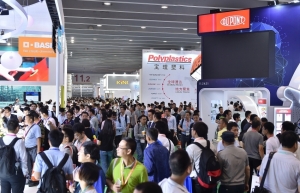

To swim with the tide is the key to survival. But how? Answers are to be found at Chinaplas 2018, Asia's No.1 plastics and rubber trade fair, replete with cutting edge solutions from around the world, featuring the latest materials, equipment, and technology, providing a “high-speed train” for businesses to join the bandwagon.

|

| "Lightweighting" will play an important role in this year's Chinaplas |

“Slimming” packaging in full gear

Reducing resource consumption and packaging-waste at the source is not exactly a new idea, and "lightweighting" has been gathering momentum in recent years. Enterprises with leading technologies are already on the move, like Nestlé. They have reduced the weight of their mineral water bottles by 30-45 per cent to help saving the environment.

Ingeo-based Earthfirst ®UL, to be displayed by NatureWorks LLC at Chinaplas 2018, is an outstanding sealant with proven mechanic properties and performance. EarthFirst ®UL is ideal for food packaging applications like disposable pillow pouches, small coffee packets, gusseted stand-up pouches, frozen foods, and multi-wall bags. EarthFirst ®UL forms superior seals at lower initial sealing temperatures.

Taizhou Huangyan Fow Mould Co., Ltd. will showcase IML box mould/thin-wall mould at Chinaplas 2018. Fow Mould can be used to make various kinds of bucket mould, and of every size—from 50ml to 2l—in every shape, from square and round to oval containers, for every application—ice cream, cheese, chocolate, fast food, and so on. The thin-wall mould can reduce packaging weight.

A bright future for biodegradable plastics

Biodegradability is a rising star in packaging. At the beginning of 2018, the government of the People’s Republic of China released a new version of the "Packing for Express Service" series of national standards and made it clear for the first time that courier packaging should make use of biodegradable plastics.

According to statistics, the courier industry in China used about 14.7 billion plastic bags in 2016. It is inevitable to resolve the conflict between packaging and the environment and accelerate the pace to adopt green, biodegradable materials and technology.

PHA bio-based fully biodegradable polymers from Sogreen Technology Co., Ltd. can be decomposed by microorganisms within 3-6 months. The polymers can substitute 50 per cent of plastics. It can be used for the production of disposable products, such as mulch films, plastic bags, and foam lunch boxes.

Zhejiang Hisun Biomaterials Co., Ltd.’s REVODE polylactide resin is made from 100 per cent renewable resources. REVODE is an environmentally-friendly material, produced with low carbon-emission methods. Products made of REVODE are 100 per cent biodegradable and widely used in disposable tableware and packaging bags. Visitors can find out more about this resin at Chinaplas 2018.

|

| Chinaplas 2018 will feature several revolutionary solutions to improve the quality of packaging |

What is the appeal of multifunctional packaging?

It has been derived that the amount of food wasted in Asia every year due to packaging problems is enough to feed more than a hundred million people. A common cause of such waste is rotting or the growth of mould within shelf life. Is there a way to improve and use suitable materials to ensure or even extend shelf lives?

The development of multifunctional materials with good barrier properties and heat- and UV-resistance, antimicrobic properties that are permeable yet oxygen-blocking, can be an answer.

Multi-layer flexible packaging films require specialty barrier extrusion lines. Films produced by Hosokawa Alpine Aktiengesellschaft’s Film Extrusion Division prevent the infiltration of oxygen, nitrogen, carbon dioxide, and water vapor. They also preserve the aromas and flavours of the finished product. It is recommended to use on 7-, 9- or 11- layer lines—the more layers the more options for users to engineer and tailor their film products while saving raw material costs.

Chinaplas 2018 will run on April 24-27, 2018. For walk-in visitors, RMB 50 and RMB 80 will be charged for a one-day and a four-day pass, respectively. Visitors can enjoy admission discount through online pre-registration from now till April 18, 2018, at an early-bird rate of RMB 50 for a four-day pass.

| Advanced technology at Chinaplas 2018 accelerates automotive industry The world is shifting into high gear on sustainability. China, one of the major manufacturing countries of cars, has put emphasis on the development of ... |

| A wealth of exciting events at Chinaplas 2018 The development of plastic and rubber technologies has been steamrolling ahead in current years. Chinaplas, as a leading trade fair, offers a global technology-oriented platform ... |

| Chinaplas 2018: must-see exhibition for plastics and rubber providers In line with the unprecedented development of technology, Chinaplas, Asia’s No.1 plastics and rubber trade fair is evolving from a business platform for materials and ... |

| Chinaplas 2018 plastics exhibition moves to grander venue in Shanghai Chinaplas 2018 will be held for the first time at the National Exhibition and Convention Centre (NECC) in Hongqiao, Shanghai, China, during April 24-27, showcasing ... |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- NAB Innovation Centre underscores Vietnam’s appeal for tech investment (January 30, 2026 | 11:16)

- Vietnam moves towards market-based fuel management with E10 rollout (January 30, 2026 | 11:10)

- Vietnam startup funding enters a period of capital reset (January 30, 2026 | 11:06)

- Vietnam strengthens public debt management with World Bank and IMF (January 30, 2026 | 11:00)

- PM inspects APEC 2027 project progress in An Giang province (January 29, 2026 | 09:00)

- Vietnam among the world’s top 15 trading nations (January 28, 2026 | 17:12)

- Vietnam accelerates preparations for arbitration centre linked to new financial hub (January 28, 2026 | 17:09)

- Vietnam's IPO market on recovery trajectory (January 28, 2026 | 17:04)

- Digital economy takes centre stage in Vietnam’s new growth model (January 28, 2026 | 11:43)

- EU Council president to visit Vietnam amid partnership upgrade (January 28, 2026 | 11:00)

Tag:

Tag:

Mobile Version

Mobile Version