MHI rolls out cross-industry solutions

|

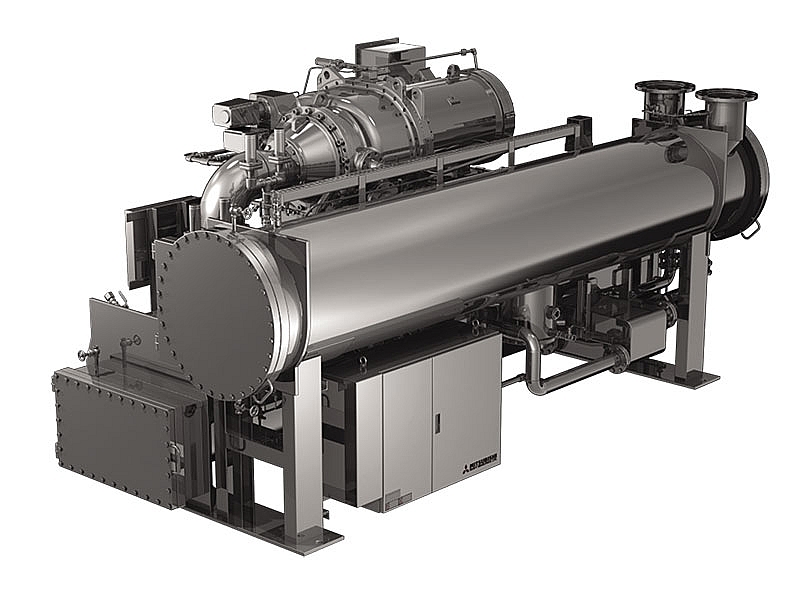

| MHI Group’s centrifugal chillers can serve companies from various industries – from semiconductor, automotive, and chemicals manufacturing plants to hotels, food suppliers, hospitals, and sports facilities |

Jun Shirota, general manager of Mitsubishi Heavy Industries (MHI) in Vietnam, shared with VIR, “Vietnam is one of our key markets in the region due to the country’s stable economic growth as well as its large, and still growing, young population. It currently accounts for around 5 per cent of our total sales in the Asia-Pacific region, and we expect it to grow further in the coming years. We are looking to promote cross-industry solutions to drive the continued growth of our business in the country.”

One proven advantage that MHI Group has over competitors lies in its broad and cross-industry solutions – products and technologies that serve and are applicable in different industries. One example is its expertise in air quality. MHI Group not only offers Air Quality Control Systems (AQCS) for industrial use like in power plants through group member Mitsubishi Hitachi Power Systems, but also for residential use, and centrifugal chillers in various sizes and applications for factories, office buildings, and shopping complexes.

Drawing from the engineering and manufacturing expertise accumulated in its long history of leadership in power generation systems, industrial and urban infrastructure, specialised industrial machinery and equipment, defence and aerospace, MHI Group can also provide integrated solutions to meet the individual needs of clients from different sectors. Specifically, MHI Group hopes to introduce its total package solutions that combines different products and services, including custom-built co-generation power systems, AQCS, and even logistics products.

According to Shirota, such solutions can provide numerous benefits to customers such as operational efficiency, energy usage optimisation, and reduction of production costs through state-of-the-art technologies. MHI Group hopes that the concept of cross-industry solutions will help the company unlock more opportunities in Vietnam, especially in the three sectors it has identified as priorities: industrial parks, airports, and urban development.

According to Shirota, the local industrial parks sector is expected to further expand as Vietnam strengthens its position as a lower-cost global manufacturing hub. This is underscored by the increase in the number of foreign investors, including those from Japan, aiming to expand their local manufacturing activities.

Shirota emphasised the high projected growth of Vietnam’s manufacturing facilities, which have a higher demand for energy than assembly factories. MHI Group is eyeing such factories, including manufacturers of plastics, fertilisers, electrical equipment, and automotive parts, as potential customers for its solutions.

“Our total package solutions can make existing and new factories more efficient. Factories which already have a stable production plan and customer base can easily calculate the benefits of our solutions. Meanwhile, newly established ones which have applied our solutions during the development phase stand to benefit in the long term,” he added.

MHI Group also sees a lot of growth potential in the airports sector. Asia is expected to account for more than half of new airline passengers over the next 20 years, with Vietnam among the world’s fastest-growing markets. To support this development, MHI Group hopes to introduce some of its automated guideway transit products, such as Automated People Mover systems which are composed of driverless trains that transport people from one area of the airport to another. Meanwhile, the urban development sector also presents tremendous opportunities for MHI Group. Vietnam, along with the rest of the Asia-Pacific region, is urbanising at an unprecedented speed. Considering this, it is important to ensure urbanisation is done in a way that keeps Vietnamese cities liveable.

MHI Group plans to introduce its waste-to-energy systems that can generate electricity from the incineration of municipal solid waste. Moreover, it also aims to bring in its SMASH (SMart ASH Treatment System) technology, which can convert the ash produced from the incineration into material for cement used in construction. MHI Group hopes its waste-to-energy solutions can help meet the growing waste management needs of Vietnam and its industries. The development of cross-industry solutions underscores MHI Group’s commitment to supporting Vietnam’s sustainable development and continued growth. Furthermore, the company’s vast manufacturing expertise and experience can help elevate local industries.

“We will work closely with our Vietnamese partners to understand their requirements and provide tailor-made solutions that respond to their needs,” Shirota said. “We are focused on enabling our partners to conduct their operations efficiently so that they, in turn, can better serve their respective markets and customers.”

| Vietnam: a cornerstone of MHI Group’s Asia strategy As part of its business strategy in Asia, Mitsubishi Heavy Industries Group (MHI) looks to bring more innovative solutions to Vietnam. Jun Shirota, general manager ... |

| MHI looks to power Vietnam’s future Mitsubishi Heavy Industries Group delivers innovative and integrated solutions across a wide range of industries in Vietnam. Jun Shirota, general manager of Mitsubishi Heavy Industries ... |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- PM outlines new tasks for healthcare sector (February 25, 2026 | 16:00)

- Ho Chi Minh City launches plan for innovation and digital transformation (February 25, 2026 | 09:00)

- Vietnam sets ambitious dairy growth targets (February 24, 2026 | 18:00)

- Masan Consumer names new deputy CEO to drive foods and beverages growth (February 23, 2026 | 20:52)

- Myriad risks ahead, but ones Vietnam can confront (February 20, 2026 | 15:02)

- Vietnam making the leap into AI and semiconductors (February 20, 2026 | 09:37)

- Funding must be activated for semiconductor success (February 20, 2026 | 09:20)

- Resilience as new benchmark for smarter infrastructure (February 19, 2026 | 20:35)

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

Tag:

Tag:

Mobile Version

Mobile Version