Reviving a new life cycle for plastic waste

Surpassing over 100 initiatives aimed at enhancing the capacity for collecting and recycling plastic packaging, the five most promising ideas for expansion in Vietnam were selected for recognition at the Plastic Circular Innovation Solutions event last month.

Vang Vien Thong, CEO of Vietnamese textile brand Repeet, one of the projects honoured at the Ministry of Natural Resources and Environment (MoNRE) event, stated that their mission is to make sustainable materials popular in the Vietnamese market and expand abroad.

“The fashion industry is a major contributor to global plastic pollution, producing around 92 million tonnes of plastic waste annually. Our goal is to change the status quo in the garment industry and create clean fashion for the future,” Thong said.

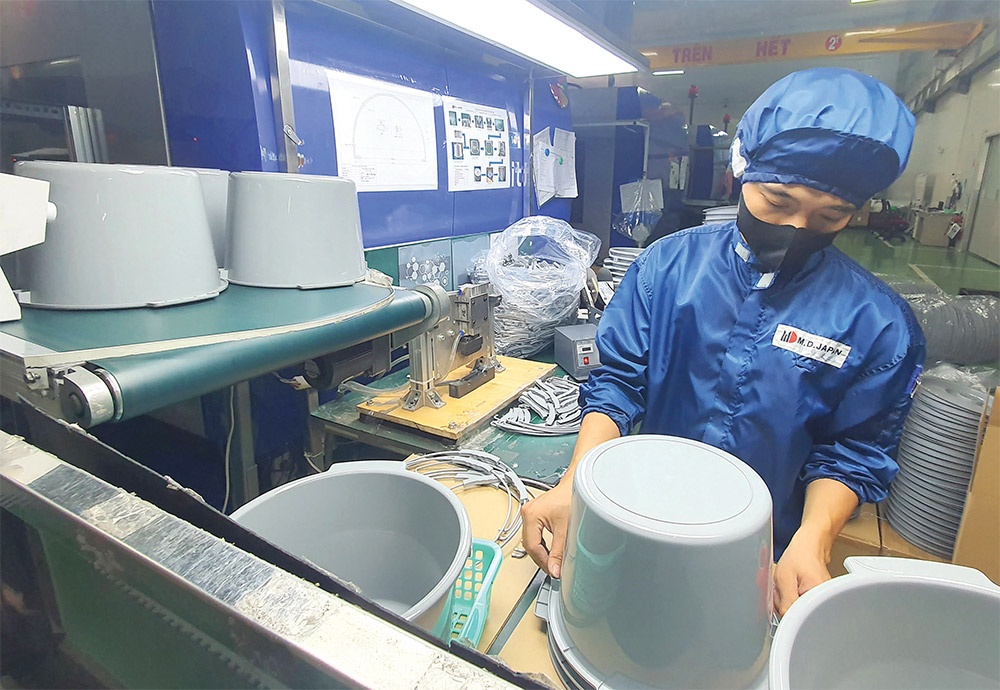

|

| Many major businesses are optimising reduction of virgin plastic from the design stage onwards |

Repeet specialises in manufacturing sustainable materials and garments using recycled polyester yarn from PET bottle waste. Typically, a Repeet t-shirt containing 20 per cent recycled content requires 7-10 plastic bottles, while a T-shirt made entirely from recycled polyester needs 20-25 bottles.

Thong acknowledged that the biggest barrier to developing the project lies not in the collection and recycling processes, but in testing the specifications to ensure they meet the standards for producing yarn and weaving fabric. “Vietnam lacks small laboratories, so whenever we conduct fabric sample tests, we often have to use large laboratories at a very high cost,” he said.

Despite facing some challenges as the first enterprise in Vietnam to use recycled plastic bottles as raw materials for fashion products, Thong noted that the products are selling well in Vietnam because their prices are only 5-10 per cent higher than traditional products.

In the past two years, Repeet has collected and recycled over two million plastic bottles, producing more than 200,000 metres of fabric from recycled plastic to serve clients in the fashion, food and beverages, banking, and education sectors in Vietnam. It is anticipated that in early 2025, the project will export its first order of recycled fabric to a company in Japan.

Each year, Vietnam generates approximately 1.8 million tonnes of plastic waste, of which between 300,000-750,000 tonnes end up in the sea, according to statistics from the MoNRE. However, only around one-quarter of this waste is recycled and reused by facilities and businesses. Methods for managing plastic waste remain limited, with 90 per cent of plastic waste being landfilled or incinerated, and the rest being recycled.

The dangers posed by plastic waste pollution have created an opportunity for the development of a circular plastic economy. Instead of the traditional linear model of production, use, and disposal, plastic waste will be collected, sorted, and recycled into new products, helping to minimise waste and maximise resource use.

Nguyen Thi Bich Van, Unilever Vietnam’s country head, remarked that the transition from using and discarding plastic to recycling it is a shift that requires the collaboration of all partners in the plastic value chain.

“From the design phase of product packaging, we aim to optimise the reduction of virgin plastic and increase recyclability while ensuring product quality and consumer experience,” Van said. “To date, we have reduced more than half of virgin plastic, and 64 per cent of our packaging is recyclable. Unilever Vietnam has also achieved plastic neutrality, meaning we can collect and recycle more plastic than we introduce to the market.”

Additionally, the company has launched numerous collaborative projects to support recyclers like Duy Tan and Vietcycle, providing better livelihoods for waste pickers. Unilever is also contributing expertise and financial support to small- and medium-sized enterprises in the recycled plastic industry in Vietnam.

Phan Dang Bao, head of Cooperation and Sustainable Development at Lam Tran Plastic Recycling, emphasised that collecting and sorting plastic waste in Vietnam still faces numerous challenges due to a lack of clear standards and methods for collection and sorting at the source.

“To ensure the quality of input raw materials, the company must establish its standards for scrap materials while building a team for collection and sorting at each location to survey, evaluate, and propose the most effective solutions,” Bao said.

Currently, Lam Tran’s recycling capacity is estimated at 1,000 tonnes per month, equivalent to about 2,000 tonnes of plastic waste material. “To put it into perspective, our monthly collection is about 12 million sq.m, which is equivalent to 1.5 times the area of District 1 in Ho Chi Minh City,” Bao added.

Bao hopes that regulatory agencies will continue to support recycling companies in developing collection systems and establishing sorting facilities. In this regard, the implementation of regulations regarding extended producer responsibility since the beginning of this year is seen as a stepping stone to motivate recycling efforts and reduce plastic waste in Vietnam.

Le Cong Thanh, Deputy Minister of Natural Resources and Environment, said that plastic waste is now present everywhere, negatively impacting the environment and affecting all areas from urban to rural areas and even the oceans.

“Vietnam is committed to reducing and combating plastic waste and promoting a circular economy, while continuing to develop and implement policies and laws to support innovative and practical solutions and encourage responsible consumption,” he said.

According to Thanh, Vietnam has been making efforts to implement various activities to reduce and combat plastic waste pollution, such as participating in global discussions on the global agreement on plastic pollution, which is expected to be adopted by the end of this year in South Korea. The 2020 Environmental Protection Law stipulates the extended producer responsibility, which came into effect at the start of 2024.

“This is an important step in Vietnam’s environmental policy, requiring producers and importers to take responsibility for collecting, recycling, and treating their products and packaging, including plastic waste, after consumers discard them,” Thanh added.

“Full and serious implementation will contribute to the development of the domestic recycling industry, gradually reducing dependence on imported scrap materials, and creating conditions for building a circular economy ecosystem where resources are used efficiently and not wasted.”

| Marie Samuelsson, CEO, Ecolean

We understand that we can only minimise the full environmental impact of packaging by addressing its entire life-cycle and continuously striving to close resource loops. We promote life-cycle resource efficiency by reducing the amount of packaging material used, transported, and also disposed. Wasteful and inefficient societies are driving climate change, biodiversity loss, and pollution on a global scale. At the same time, huge quantities of food are wasted in a world where millions do not have enough to eat. As much as 10 per cent of a conventional one-litre yoghurt package may go to waste, as it cannot be squeezed out of the packaging. Our packages can help waste less food as they are easy to empty and allow consumers to completely empty the package. Since Ecolean was founded in 1996 in Sweden with our lightweight philosophy, we have challenged the food packaging industry and saved resources along the way. This has been our guiding star, and we continue to provide the world with our lightweight and resource-efficient packaging solution that minimises food waste and ensures food safety. Ecolean is the only packaging supplier with environmental product declarations (EPDs) for the entire packaging system, including both packages, filling machines and production plants. These EPDs provide the ability to measure and compare different packaging solutions – and to ultimately optimise life-cycle sustainability. Our EPDs are part of our work to shift the focus to the entire life-cycle of a product and not just the materials used in the product itself. We believe that full transparency from cradle to grave contributes to innovation, sustainability and trust. The company’s Sustainability Roadmap 2030 is a cornerstone of its commitment to becoming a more sustainable business. The roadmap includes ambitious targets to not only minimise environmental negative impacts, but to also optimise the positive benefits of light-weight packaging on society. |

| Tourism industry in Hue strives to cut plastic waste Following a year since its implementation, the central province of Thua Thien-Hue's initiative to cut plastic waste in tourism has yielded significant results, enhancing the city's environment to be more green, clean, and appealing for tourists. |

| Supportive policies crucial for retail plastic reduction While major retailers are spearheading plastic reduction efforts, a joint initiative with government and environmental groups is needed to align business interests with sustainability goals. |

| Promoting plastic waste collection and recycling towards a circular economy Suntory PepsiCo Vietnam, in tandem with VietCycle, held a training course on August 23 for informal workers who collect waste to show them how to classify everyday items that can be recycled. |

| Vietnam urged to accelerate fight against plastic waste Vietnam is being cautioned about the increasing levels of plastic waste entering its water environments, undermining both environmental quality and the country’s sustainable development efforts. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- PM outlines new tasks for healthcare sector (February 25, 2026 | 16:00)

- Ho Chi Minh City launches plan for innovation and digital transformation (February 25, 2026 | 09:00)

- Vietnam sets ambitious dairy growth targets (February 24, 2026 | 18:00)

- Masan Consumer names new deputy CEO to drive foods and beverages growth (February 23, 2026 | 20:52)

- Myriad risks ahead, but ones Vietnam can confront (February 20, 2026 | 15:02)

- Vietnam making the leap into AI and semiconductors (February 20, 2026 | 09:37)

- Funding must be activated for semiconductor success (February 20, 2026 | 09:20)

- Resilience as new benchmark for smarter infrastructure (February 19, 2026 | 20:35)

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

Tag:

Tag:

Mobile Version

Mobile Version