Manufacturing soy milk utilising Aseptic technology

Tan Hiep Phat's Aseptic technology was created by GEA, a German firm and one of the world's major system providers for the food, beverage, and pharmaceutical industries. Fundamentally, it is a series of machine systems that are automatically and tightly interconnected.

With the Aseptic technology line, germs will be prevented from entering the beverage manufacturing process, from processing raw materials to blowing bottles and filling and sealing goods.

|

| After more than six months on the market, people are growing fond of Number 1 Soya Canxi |

Before processing, the creation of Number 1 Soya Canxi starts with stringent quality control over the selection of soybean seed materials.

Using Japanese technology, soybean seeds are peeled and extracted to get nutrients, therefore preserving nutritious ingredients such as protein, fat, and carbohydrates. The soy milk solution will then be transported to a centrifugal filtration system to thoroughly remove the soybean residue to produce a milk product with a smooth consistency.

Following mixing, there will be ultra-high temperature (UHT) sterilisation. From the aseptic tank, a Soya Canxi soy milk solution enters the filling and capping system. To maintain the highest level of quality, all preforms and bottle caps are produced in-house.

As opposed to previous methods in which the product simply undergoes a single step of pasteurisation and filling in an open environment, allowing germs to readily infiltrate, the aseptic cold extraction process has totally eliminated this issue.

Specifically, the soy milk solution is sterilised and disinfected by a high-temperature, short-duration heat treatment lasting between 2-5 seconds. The product is then promptly chilled.

|

| Aseptic technology is used in the manufacture of Number 1 Soya Canxi |

The filling and capping phases must guarantee five sterility-related criteria, including sterile bottles, sterile caps, sterile water, sterile items, and an aseptic extraction environment.

Sterile goods devoid of preservatives have been manufactured to fulfil the present stringent food safety standards. In addition, the filling is performed at a low temperature to prevent the loss of nutrients from the pure soybeans due to the influence of temperature. This is a twofold innovation by Aseptic that allows Number 1 Soya Canxi to maintain its nutritional excellence and natural taste and colour. Immediately after the filling operation, the sterile healthy drink will be automatically blocked and packaged.

Since its introduction at the end of 2021, Number 1 Soya Canxi has swiftly become a customer's favourite due to its exceptional product quality.

|

Number 1 Soya Canxi soy milk not only satisfies thirst and replenishes the body's nutrients and calcium but also promotes a healthy and convenient lifestyle.

In addition to Number 1 Soya Canxi, Tan Hiep Phat utilises Aseptic technology for its energy drinks, green tea, and refreshing tea products, including Number 1 Energy Drink, Zero Degree Green Tea, and Dr. Thanh Refreshing Tea.

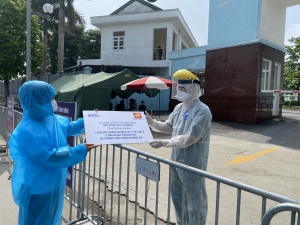

| Tan Hiep Phat rises strongly thanks to bravery and creativity Tan Hiep Phat Group has celebrated its 27th anniversary with the COVID-19 pandemic impacting the economy. However, the group has overcome the difficulties and achieved success thanks to the bravery, entrepreneur spirit, and the relentless creativity of the Tran family of business people led by Dr. Tran Qui Thanh. Tran Uyen Phuong, deputy CEO of Tan Hiep Phat Group talked with VIR’s Hai Yen about the story of the group. |

| Core values enable Tan Hiep Phat Group to stay firm amid pandemic Despite suffering myriad hardships due to COVID-19, Tan Hiep Phat Group, a major beverage firm based in Ho Chi Minh City, has taken an array of measures to co-exist with the pandemic and gradually stabilise production. |

| Tan Hiep Phat Group shows outstanding efforts Tan Hiep Phat Group has a 28-year history of establishing and expanding its domestic and international presence in 20 nations and regions. Founder of Tan Hiep Phat Group, general director Tran Qui Thanh, and deputy general director Tran Uyen Phuong told VIR's Hai Yen that the organisation's unity in pursuing its goals is the most important factor in achieving such remarkable growth. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

- Strengthening the core role of industry and trade (February 19, 2026 | 08:35)

- Future orientations for healthcare improvements (February 19, 2026 | 08:29)

- Infrastructure orientations suitable for a new chapter (February 19, 2026 | 08:15)

- Innovation breakthroughs that can elevate the nation (February 19, 2026 | 08:08)

- ABB Robotics hosts SOMA Value Provider Conference in Vietnam (February 19, 2026 | 08:00)

- Entire financial sector steps firmly into a new spring (February 17, 2026 | 13:40)

- Digital security fundamental for better and faster decision-making (February 13, 2026 | 10:50)

- Aircraft makers urge out-the-box thinking (February 13, 2026 | 10:39)

Mobile Version

Mobile Version