Drastic stay-at-work scheme kicks off

|

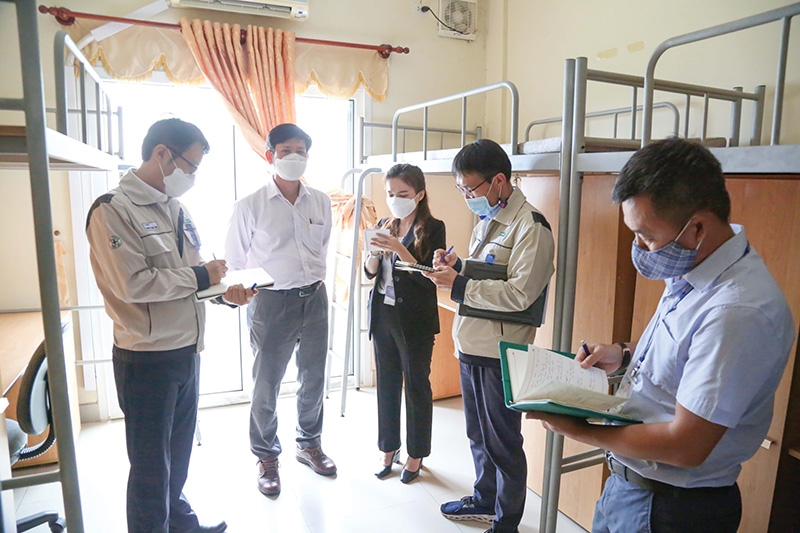

| Ho Chi Minh City businesses are working to organise safe production and accommodation for workers |

“Businesses are ready and have made plans to respond to the outbreak. That’s why we can implement Ho Chi Minh City’s stay-at-work arrangements for workers within a 24-hour deadline,” said a representative of Vietnam’s leading brewer SABECO.

She added that to not break the production and supply chain, stay-at-work employees include the production, technical, and quality control departments, as well as partners in the supply chain and medical staff.

“The focus for our company is on keeping employees safe. Workers who stay on site are equipped with sleeping places and necessary items for daily living, following safety standards. Protecting employee’s mental health has also emerged as a high priority,” she added.

On July 13, Ho Chi Minh City stated that businesses in the city would have to make stay-at-work arrangements for their workers, ensuring pandemic prevention while they will be allowed to continue production. If enterprises fail to meet the requirements, they must stop operating from July 15 until new instructions are issued. Besides SABECO, hundreds of other businesses have prepared for on-site production.

Ready to stay at work

Solutions to let employees remain at work instead of travelling back and forth from their homes each day are likely to decrease the risk of infection during the pandemic.

Since June 28, meat processor Vissan has organised on-site camps for all of its employees, meaning around 1,500 workers. The company will maintain the strategy until the city contains the coronavirus threat.

Meanwhile, Thai-backed husbandry giant C.P. Vietnam has activated the strategy for its facilities. All individuals from each location are asked to maintain social distancing measures.

Le Xuan Huy, deputy general director of C.P. Vietnam, confirmed that his company had only recently developed the plan to organise both isolation and production at the factory. Around 800 employees have been divided across various shifts to ensure social distancing, and hundreds of tents have been purchased for workers to stay at the factory.

The company supplies fresh pork with an output of 350-400 pigs a day to the city. In recent days, it has increased the output to 600 pigs per day to meet the soaring demand. The company ensures adequate supply and is keeping prices stable for six months due to its autonomy in livestock production.

INSEE Vietnam, a member of leading cement maker Siam City Cement Group, set a scenario for its facilities through business continuity plan, aiming to establish the risk profile of enterprises and the level of vulnerability to COVID-19 in terms of its impact on the 4Ps – people, processes, profits, and partnerships.

“Four out of five of our factories here have applied the stay-at-work model to protect workers, production, and supply chains of all factories. Every month, we revise the plans and reports based on the actual situation,” said Dao Nguyen Khanh, marketing and corporate communication manager of Siam City Cement Vietnam.

Quick responses

According to Ho Chi Minh City People’s Committee, there are nearly 200 enterprises registered to organise the stay-at-work model in export processing zones and industrial parks, with more than 9,300 employees staying on-site.

Besides this, Ho Chi Minh City has prepared 15 vacant land plots and 15 factories for temporary isolation camps to support enterprises.

A representative of Acecook Vietnam shared that the company has made efforts to prepare plans for workers to stay on site as well as retain workers. However, less than 50 per cent of factory workers registered to do so.

In addition, Acecook’s suppliers of raw materials are currently facing similar difficulties. Thus, there is a risk of reduced production capacity and material supply, which is leading to a projected 50 per cent decline in Acecook’s output. Despite the high input costs, Acecook is committed not to increase prices until the end of the year.

However, some small factories decided to temporarily shut down operations as they fail to meet the new requirements.

Anatolijus Fouracre, CEO of IT producer Swiss Post Solutions in Quang Trung Software City, complained that the main challenges include having only 24 hours to respond, and not knowing how long staff will need to live on site. “Our company has set up a solution in Ho Chi Minh City and we hope we can continue to operate,” shared Anatolijus.

Neighbouring provinces of Ho Chi Minh City – including Binh Phuoc and Long An – have meanwhile attempted to also apply the stay-at-work model.

Last week, the Ministry of Labour, Invalids and Social Affairs, the Vietnam General Confederation of Labour, and the Vietnam Chamber of Commerce and Industry jointly signed a document for both isolation and production in enterprises and business establishments nationwide, giving guidance and recommendations for businesses to prevent the pandemic while maintaining production.

| Joseph Perucca - General director, GIVI Vietnam

Our company welcomed the new government provisions requesting the stay-at-work model. Fortunately, with foresight, we had already organised safety standards and prepared both spaces and equipment suitable for allowing our workers to stay at their workplaces by providing meals, personal hygiene facilities, and overnight stay options on site. Nevertheless, operating personnel was drastically reduced to a minimum sufficient to carry out production and guarantee customers’ supplies. The rest of the staff had the opportunity to organise themselves to work remotely and carry out work at any time, so despite everything, this situation has not negatively affected our productivity, our standards, and our ability to maintain supply for the rest of our worldwide partners. Although there is a lot of information on vaccination plans, confusion and concerns remain. We hope that clear and proactive action from the government will prompt quick vaccinations. Many companies in Vietnam, like ours, are resorting to extraordinary measures to stay active and connected to the global market. Thus, we need a vaccination plan covering the entire population quickly, as we risk falling behind the rest of the world with devastating consequences, both economically and socially. Lee Younbong - Director of Management Doosan Vina

The pandemic is very unpredictable, seriously affecting the production and business activities of many companies in Vietnam. To overcome all challenges, Doosan Vina has actively implemented the twin goal of both strengthening anti-pandemic measures and ensuring the production activities. Doosan Vina has set up the stay-at-work model for over 1,000 employees to respond to the emergency. We have also set up a separate quarantine area at the block A of the company’s dormitory, with 84 fully equipped rooms to ensure employees’ health. Thanks to determination to fight the pandemic, Doosan Vina’s production chain remains steady and intact. Nearly 3,000 employees are currently manufacturing for several projects to supply domestic and foreign customers. Sisnce the beginning of the year, Doosan Vina has exported and delivered 18,000 tonnes of products to Japan, Thailand, Indonesia, and Vietnam, contributing to improving the province’s export turnover and the stability of social security. It has also created stable jobs and income for nearly 3,000 employees, of which more than 80 per cent are locals. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Themes: COVID-19

- 67 million children missed out on vaccines because of Covid: UNICEF

- Vietnam records 305 COVID-19 cases on October 30

- 671 new COVID-19 cases recorded on October 1

- Vietnam logs additional 2,287 COVID-19 cases on Sept. 21

- People’s support decisive to vaccination coverage expansion: official

Related Contents

Latest News

More News

- Foreign leaders extend congratulations to Party General Secretary To Lam (January 25, 2026 | 10:01)

- 14th National Party Congress wraps up with success (January 25, 2026 | 09:49)

- Congratulations from VFF Central Committee's int’l partners to 14th National Party Congress (January 25, 2026 | 09:46)

- 14th Party Central Committee unanimously elects To Lam as General Secretary (January 23, 2026 | 16:22)

- Worldwide congratulations underscore confidence in Vietnam’s 14th Party Congress (January 23, 2026 | 09:02)

- Political parties, organisations, int’l friends send congratulations to 14th National Party Congress (January 22, 2026 | 09:33)

- Press release on second working day of 14th National Party Congress (January 22, 2026 | 09:19)

- 14th National Party Congress: Japanese media highlight Vietnam’s growth targets (January 21, 2026 | 09:46)

- 14th National Party Congress: Driving force for Vietnam to continue renewal, innovation, breakthroughs (January 21, 2026 | 09:42)

- Vietnam remains spiritual support for progressive forces: Colombian party leader (January 21, 2026 | 08:00)

Tag:

Tag:

Mobile Version

Mobile Version