Data collection - the “key” to unlocking Industry 4.0

|

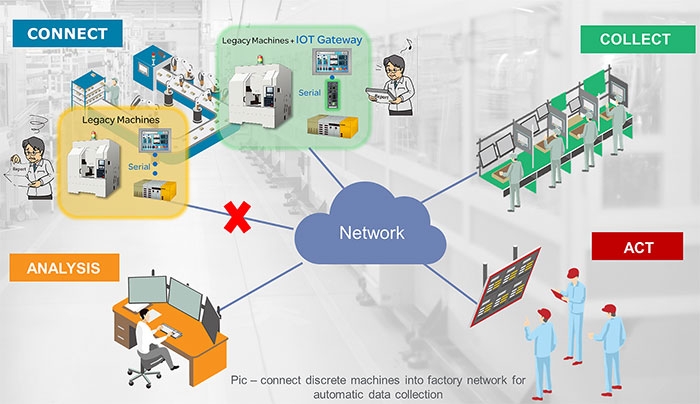

| Connect discrete machines into factory network for automatic data collection |

Data is the key, so how best to collect it to take advantage of the technology breakthroughs in Industry 4.0?

The benefits of automatic data collection

Thanks to communication networks, machines and users are “communicating” with each other through the collected data. Users can easily look up the operating history of the machine; review the problems with sufficient information to find the optimal remedies; or to retrieve and study reports on productivity and yield. The data is automatically collected in certain cycles, helping users save time and significant efforts.

Auto-collecting methods have overcome the limitations of manual methods: constraint in recognising machine status; difficulty in retrieving all insight data in the event of an incident; human error when using hand-written reports. These limitations result in cost and time inefficiency. Obviously, when the data source is collected automatically, the performance and productivity of the devices are significantly improved.

Despite awareness of the importance of auto-collecting data at regular intervals, most of the small and medium enterprises in our country have not fully transformed the manual operation due to limitations of connection ability of legacy machinery.

What is the solution?

|

| Schneider Electric’s new IOT Gateway enables easy data collection |

Legacy machines still play an important role in factories as they ensure operation quality and production efficiency. However, their communication with the whole system is not optimised because they use the out-of-date control devices HMI & PLC (Human-Machine Interface and Programmable Logic Controller). Old HMIs and PLCs do not support Ethernet communications - the fastest and most popular high-speed communications standard today thanks to its ease-of-use. At the same time, these HMIs & PLCs may have only one communication port which is used for connecting themselves, so they cannot connect to the system. Upgrading these old machines is costly and time consuming, and causes a risk of productivity loss due to incompatibility and downtime.

As the world-leading manufacturer of industrial HMI, Proface by Schneider Electric has launched the IOT Gateway product that will allow you to connect your old machines to the data centre. Proface IOT Gateway will be installed between the PLC and HMI, collecting the necessary data from the PLC to the server without halting the machine, without interrupting the connection, and without altering the existing program. The connection is extremely easy – requiring just configuration through software, and no complicated programming.

When combining this IOT Gateway with Pro-Server EX software, users can easily gather information to the data server in a variety of formats and methods, including Excel files, csv, USB or SD memory sticks, saving to PC via Pro-Server EX, and downloading from the web browser. All data through the IOT Gateway can also be sent to the SQL data centre for storage and extraction whenever needed. It also supports the display of data information on tablets or PCs.

From the above advantages, Proface by Schneider Electric’s IOT Gateway enables automatic collection of data – the “key” from existing legacy machines. This helps to reduce costs and creates flexibility, ease of use, and reliability. It will be a powerful tool for businesses to remain on track with Industry 4.0.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Efficient technology solutions key factors in energy transition (September 25, 2024 | 09:00)

- Sao Do Group gears towards energy savings (December 07, 2023 | 12:01)

- Vice President Vo Thi Anh Xuan visits Copenhagen Infrastructure Partners headquarters (November 23, 2023 | 10:37)

- A wind turbine tower collapses in China (November 20, 2023 | 19:36)

- Vietnam has massive potential for offshore wind energy (March 17, 2023 | 16:29)

- Rooftop solar event entices EPC contractors and investment funds (March 09, 2023 | 07:50)

- GreenYellow acquires 49.5MWp solar farm of French IPP Qair in Vietnam (November 25, 2022 | 08:00)

- Eaton contributes to Vietnam’s low-carbon economy (November 20, 2022 | 19:00)

- Proposals to promote Vietnam's energy transition (November 12, 2022 | 22:02)

- How intelligent lights make cities smarter, safer and greener (November 04, 2022 | 09:00)

Tag:

Tag:

Mobile Version

Mobile Version