Technology paving the way for the industrial revolution

The Taiwan Expo will return to Vietnam this week to showcase the powerful Industry 4.0 capabilities of Taiwanese manufacturers. The expo will be held virtually on July 21-23 to peruse the most advanced industrial products from a line-up of 195 of major enterprises from the fields of household and consumer electronics, ICT, cosmetics, health and sports, to transportation and machinery, as well as lifestyle sectors.

Taiwan has long been a regional and global powerhouse, consistently reporting some of the highest growth rates in the world on the back of a relentless industrial march ahead. As one of the four Asian Tigers – a title it has earned through sustained aggressive industrialisation – the Taiwanese economy has laid world-leading foundations to embark on a journey of innovation and digitalisation. Now Taiwanese producers are not only riding, but leading the Industry 4.0 wave, rolling out innovations and solutions that have transformed the world.

The Taiwan Expo 2021 will bring many of these cutting-edge technological advances to Vietnamese industry leaders and professionals to provide a glimpse into what the future might hold for their operations and extend a hand for cooperation to reach that future a step ahead of competition.

At the expo, local industrialists can look forward to Taiwan Excellence Award-winning products from the renowned Sun Firm Machinery Industrial Co., Ltd. and RenAn Information Technology Co., Ltd.

| Taiwan Excellence is an annual award honouring Taiwan’s outstanding innovative products that provide tremendous value to users worldwide. All products carrying this symbol have been selected as winners of specific Taiwan Excellence Awards based on outstanding research and development, design, quality, marketing, and Made-in-Taiwan merits. Initiated by the Bureau of Foreign Trade in 1992, Taiwan Excellence has gain recognition in over 100 markets worldwide. Returning with the Taiwan Expo 2021 from July 21 to 23 with a completely new 3D format of online exhibition, Taiwan Excellence and 49 top-tier award-winning brands in various sectors will offer breakthrough solutions that bring users into the lifestyle of smart living in the 4.0 era. Not only will Vietnamese consumers now join the special virtual version of the Expo, exploring more detailed information and feasting their eyes on Taiwanese cutting-edge innovations, but they can also interact with suppliers easily anytime, anywhere at the event. Register now at www.taiwanexpo.vn and get to know more about the awarded products at www.facebook.com/taiwanexcellence.vn. |

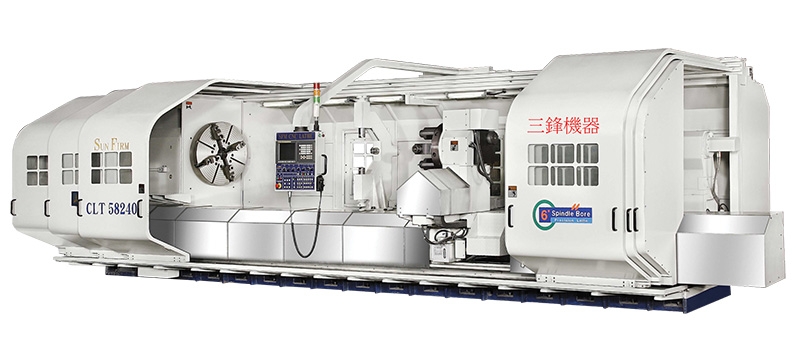

Sun Firm flat-bed computer numerical control lathes

Sun Firm’s multi-axis simultaneous motion multiple guideways heavy-duty smart CNC lathe

The go-to brand in the metalworking industry for industrial lathe machines, Sun Firm Machinery boasts 62 years of professional experience in the design and manufacturing of the most complete portfolio of horizontal heavy-duty giant computer numerical control (CNC) lathe and heavy-duty precision lathes in Taiwan.

Capable of meeting all machine type requirements with the most diverse specifications as well as related accessories, Sun Firm is steadily building up its reputation across the globe and is an ideal choice for businesses in the heavy industry.

Adopting a modular design, the company’s products offer high customisability to meet a spectrum of needs from customers, Sun Firm boasts the fastest delivery times in the global horizontal giant lathe industry, earning the trust and reliance of customers with each successful installation.

As the motto “When you buy lathe, you must choose Sun Firm” is gradually embedded in producers’ minds over the world, the company’s products are now widely used in the steel industry and metal cutting, energy exploration and generation, as well as automobile and motorcycle production, among others.

Sun Firm lathe machines were designed with a highly reliable, rigid integrated body structure resting on a stable bed structure to provide high-quality precision during heavy-duty cutting. Equipped with a spindle motor that can provide full power output even at low rotation speeds, Sun Firm’s award-winning flatbed CNC lathes boast industry-leading precision and processing efficiency.

This product comes with specially-designed spindles that can accommodate up to two sets of mandrels at the front and back, which is perfect for processing long tubes and bars. The turrets were designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency.

The body structure can support a robot arm, the automatic power system, and the power turret to allow for efficient treatment for manufacturers.

In addition, due to the modular design, the machines can be equipped with smart set-top boxes and sensors to provide to connect to Internet of Things architecture offering a range of smart functions.

A key selling point as manufacturers are discovering the benefits of Industry 4.0 technologies, these sensors can provide essential product visualisation capabilities to check the status of machine parts, spindle servo axes, and other tools. This visibility can empower maintenance staff to detect and address potential issues in advance, drastically reducing downtime and extending machine life cycle.

RenAn CNC operation simulation workstation

RenAn’s CNC operation simulation software-Mitsubishi M70 milling

In China, the name “RenAn” represents smart learning and safe technology. The company provides educational facilities and training institutes with CNC training equipment to support CNC skills development and machining experience to students. It also offers clients five Ladder CNC Training Courses to improve student capability while learning CNC operation.

Currently, technical colleges and machine shops cannot fully meet the needs of students and operators due to the lack of CNC training equipment. These machines represent considerable upfront investments and generate high consumable costs during teaching.

To replace real-life CNC machines and raw materials, RenAn has developed an operation simulation workstation that simulates the physical work processes with 3D graphics showing both cutting and machining processes.

Much like the simulators used for pilot training, RenAn’s workstation can be used to train students or operators into machinists without exposing them to physical danger that would come with the operation of heavy machinery. Simulation training comes with substantial savings on materials and mitigates pollution from physical production such as waste materials and oil and gas. The industrial panel offers the same functionality as real machinery with added smart learning features to help students accumulate hands-on operation skills.

RenAn’s workstations offer students and users complete simulation of the machine structure, from the spindle and the worktable to a variety of materials, cutting tools, and coolant materials. These stations can even accurately simulate the controller screens and functions of Fanuc, Sinumerik, and Heidenhain lathes.

With a single machine capable of supporting multiple purposes and lathe operation systems, they offer a cost-effective and environmentally friendly alternative to heavy-duty industrial lathes used for educational purposes. With an automatic error detection function to issue warning for wrong configurations, teachers and students no longer need to worry about operation collision problems or accidents. Instead, the machine allows them to replay processes and identify mistakes while also keeping track of the learning progress of students to ensure effective training without blind spots.

RenAn workstations provide tremendous support for educational institutions and manufacturers engaging in in-house training to meet the needs of the industry for highly trained CNC lathe operators.

Sun Firm provides the brawn, while RenAn brings the brains. But both enterprises share a commonality: they represent the world-class excellence of Taiwanese innovations. Producing the tools and knowledge for Industry 4.0 productions, Sun Firm and RenAn will be present at the virtual Taiwan Expo to showcase just that.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Related Contents

Latest News

More News

- Haiphong gains new growth impetus from strategic planning and integrated infrastructure (February 27, 2026 | 16:40)

- Kurz Vietnam expands Gia Lai factory (February 27, 2026 | 16:37)

- SK Innovation-led consortium wins $2.3 billion LNG project in Nghe An (February 25, 2026 | 07:56)

- THACO opens $70 million manufacturing complex in Danang (February 25, 2026 | 07:54)

- Phu Quoc International Airport expansion approved to meet rising demand (February 24, 2026 | 10:00)

- Bac Giang International Logistics Centre faces land clearance barrier (February 24, 2026 | 08:00)

- Bright prospects abound in European investment (February 19, 2026 | 20:27)

- Internal strengths attest to commitment to progress (February 19, 2026 | 20:13)

- Vietnam, New Zealand seek level-up in ties (February 19, 2026 | 18:06)

- Untapped potential in relations with Indonesia (February 19, 2026 | 17:56)

Mobile Version

Mobile Version