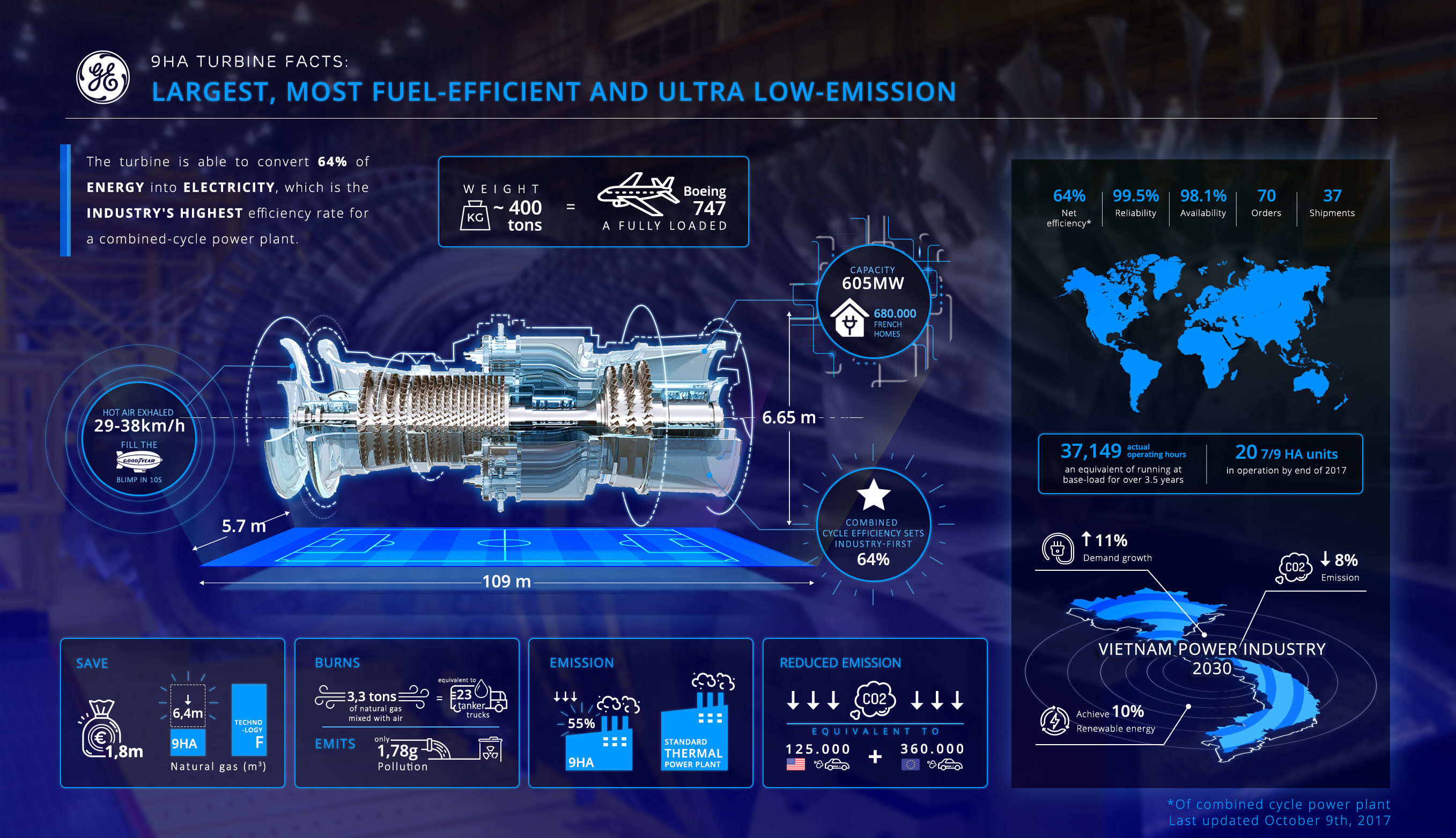

HA technology now available industry-record 64 per cent efficiency

|

| GE's HA gas turbine technology provides the highest efficiencies across the industry |

This milestone is achieved largely due to GE’s advances in additive manufacturing and combustion breakthroughs through constant innovation, coming just 18 months after GE set a world record with the HA for powering the world’s most efficient combined-cycle power plant at 62.22 per cent.

“The HA is our most advanced gas turbine technology, and we have never stopped pushing the boundaries of what it can do,” said Joe Mastrangelo, president and CEO of GE’s Gas Power Systems. “With the ability to deliver 64 per cent efficiency, GE is proud to achieve an industry first and offer customers the most efficient gas technology available in the world today.”

According to GE Power’s estimates, an additional percentage point of efficiency in gas turbines can translate into millions in fuel savings for customers globally. GE’s long-term investments in additive manufacturing play an important role in the HA’s latest efficiency upgrades.

Specifically, GE engineers developed additively-manufactured components for the 9HA’s combustion system, using metal 3D-printing to unlock new geometries for better premixing of fuel and air, leading to greater efficiency. The new combustion system has already been successfully tested at full-load and full-speed at GE’s test stand in Greenville, South Carolina.

As a result of these innovative breakthroughs, the 9HA.02 can now be quoted at 64.0 per cent net efficiency in specified conditions with a total output of 826MW in 1x1 combined cycle configuration.

Customers can order HA-based combined cycle power plants quoted at 64+ per cent in 2018, compared to the previous quoted limit of 63.7 per cent efficiency for 2017 orders. In addition, GE Power remains on track to achieve 65 per cent efficiency by the early 2020s, continuing the HA legacy as the most advanced H-class technology in the world.

The HA is a proven technology with 70+ orders to date and is being deployed by customers worldwide. Since the first HA unit was inaugurated in June 2016, more than 17 units have been put into operation, achieving more than 50,000 operating hours. Among its many benefits, the HA is an excellent flexible complement to intermittent renewable sources, capable of ramping up or down at 65MW per minute while still meeting emissions requirements to help balance grid instability.

| Harnessing lava-like temperatures to boost power Able to handle temperatures approaching 700°C, GE Power’s ultra-supercritical boiler technology is poised to bolster the next generation of coal-fired power plants. |

| GE optimises power plant efficiency The Digital Power Plant concept – an Industrial Internet solution that couples software and hardware for the analysis and optimisation of a power plant, and one which is leading the digital transformation of the global power industry, came closer to Vietnam last week with GE Power’s official introduction of this solution to Vietnam’s power producers. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Addressing Vietnam's energy challenges with aeroderivative gas turbines (February 28, 2023 | 09:33)

- How to sprint ahead in 2023’s worldwide energy priorities (February 08, 2023 | 13:55)

- Boosting Vietnam's grid stability through gas turbine technology (November 22, 2022 | 20:02)

- Healthcare trio collaborates to provide thousands of free breast scans (October 27, 2022 | 17:19)

- GE Healthcare's vision for AI-backed radiology (September 29, 2022 | 11:53)

- GE brand trio to shape the future of key industries (July 19, 2022 | 15:35)

- GE unveiling brand names and defining future (July 19, 2022 | 15:16)

- GE: the shortest route towards sustainability (July 18, 2022 | 08:00)

- Be proactive in an uncertain world (May 20, 2022 | 11:40)

- GE secures first 9HA combined cycle power plant order in Vietnam (May 16, 2022 | 17:06)

Mobile Version

Mobile Version