Fortune list names GE as a top world changer

It took considerable time and investment to boost the efficiency of GE’s gigantic HA gas turbine, affectionately known as “HArriet”, by just a few per cent. The company’s scientists used super materials and other technologies borrowed from jet engines to coax every last bit of performance from the machine, and gained the notice of Guinness when it hit 62 per cent efficiency.

In the case of HArriet, a 1,000-megawatt power plant using two of the turbines paired with steam turbines, a configuration called combined cycle, could save an estimated $50 million on fuel over 10 years from a 1 per cent gain.

Increasing efficiency also makes the already clean turbine – when it burns 3.3 tonnes of natural gas mixed with air, it results in just 6.3 fluid ounces of pollution, a volume slightly larger than a half-can of soda – even cleaner.

|

Fortune singled out GE’s work on clean energy through Ecomagination, the company’s strategy to reduce environmental impact while improving business performance for customers.

Since its inception 11 years ago, $17 billion of research and development has generated $232 billion in revenues. But other programmes like healthymagination, the company’s healthcare innovation platform, and cultural initiatives like the commitment to simplification, which accelerates innovation, decreases bureaucracy and puts long-term gains ahead of short-term thinking, have had a similarly large impact.

Below are some of the recent innovations that are keeping GE among the leading world changers.

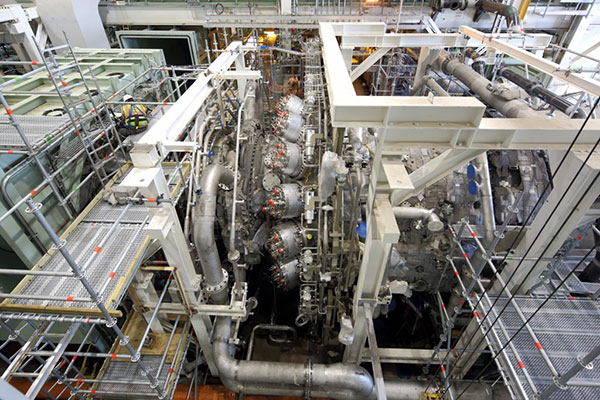

The 9HA

One other factoid about the 9HA: its ability to rapidly start and ramp up makes it the ideal partner for renewables like solar and wind, which can suddenly fall off if the clouds roll in or the wind stops. The turbine is giving its first customer, Électricité de France (EDF), the ability to integrate more renewables onto the grid.

|

| A 9HA turbine on a test stand in Greenville, South Carolina. Greenville is the world’s largest gas turbine factory. GE engineers placed some 5,000 measuring instruments and sensors on the turbine and another 2,000 on a compressor validation rig that must absorb Harriet’s 500,000 horsepower. Image credit: GE Power |

Digital wind farm

Every wind farm has its own DNA – the wind whips around the turbines and terrain in unique ways. So GE Renewable Energy has developed technology that creates a digital twin of each turbine to model how to get the most energy out of a given landscape before planting the iron in the earth.

The approach could improve a farm’s energy production by as much as 20 per cent and generate $100 million of value over the lifetime of a 100-megawatt farm.

|

| Digital wind farm designers are using a “digital twin” model (see above) residing in the cloud to build and optimize the real-world wind farm. GIF credits: GE Power & Water |

The GE9X

Aviation is booming today but that wasn’t always the case, particularly after it seemed that the industry would be permanently dampened by September 11. But a long-term commitment to research and development has yielded products like the GE9X, a next generation jet engine that promises to be so quiet and have such low nitrogen oxide emissions, it will be ecomagination-qualified.

|

| The GE9X. When Boeing decided to build the 777X jet, the next-generation version of the 777 jet, it asked GE to develop an engine to power it. Image credit: GE Aviation |

The healthymagination Mother & Child Programme

Maternal and child health remains one of the world’s most pressing problems. GE has partnered with Santa Clara University’s Miller Centre for Social Entrepreneurship to help social enterprises dealing with the health of mothers and children in sub-Saharan Africa strengthen their business models, organise and scale.

The programme gives the 15-20 participants access to and training on technologies that support health for mothers and children. This type of open innovation, where the company seeks out and supports entrepreneurs outside its walls, is key to the Ecomagination and healthymagination.

|

| Photo courtesy of Mobile Alliance for Maternal Action (MAMA) and Santa Clara University |

The Power of 1 Per cent

By binding machines together on the Industrial Internet, monitoring their health and analysing data we can make industry more efficient. Our customers work at such a large scale that a 1 per cent gain in efficiency, spread across industries, can create billions of dollars in economic gains, with corresponding environmental benefits from decreased emissions and resource use. GE’s economists estimate the Industrial Internet could add $10 to $15 trillion to global GDP in the coming decades.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Addressing Vietnam's energy challenges with aeroderivative gas turbines (February 28, 2023 | 09:33)

- How to sprint ahead in 2023’s worldwide energy priorities (February 08, 2023 | 13:55)

- Boosting Vietnam's grid stability through gas turbine technology (November 22, 2022 | 20:02)

- Healthcare trio collaborates to provide thousands of free breast scans (October 27, 2022 | 17:19)

- GE Healthcare's vision for AI-backed radiology (September 29, 2022 | 11:53)

- GE brand trio to shape the future of key industries (July 19, 2022 | 15:35)

- GE unveiling brand names and defining future (July 19, 2022 | 15:16)

- GE: the shortest route towards sustainability (July 18, 2022 | 08:00)

- Be proactive in an uncertain world (May 20, 2022 | 11:40)

- GE secures first 9HA combined cycle power plant order in Vietnam (May 16, 2022 | 17:06)

Mobile Version

Mobile Version