Celebrating 10 years of the LEAP engine programme

|

| Celebrating 10 years of the LEAP Engine programme |

On July 13, 2008, CFM International’s parent companies, GE Aviation and Safran Aircraft Engines, made history by launching the advanced LEAP-X engine programme.

“That was a great day for CFM and a bold move for GE and Safran Aircraft Engines,” said Gaël Méheust, president and CEO of CFM International. “That day, they committed to a multi-billion-dollar engine development programme that, at the time, did not have an airplane application. But the parent companies were so confident in the joint venture and its future that they also renewed the partnership agreement to the year 2040.”

The first engine application didn’t come until about 18 months later, when COMAC chose the LEAP engine to be the sole Western power plant for its new 150-passenge C919 in December 2009. A year later, Airbus chose the LEAP engine as an option for its A320 new engine option aircraft. In November 2011, Boeing made the LEAP engine the sole power plant for its new 737 MAX programme. All the while, CFM maintained a rigorous development schedule, ticking off milestones on schedule, if not ahead of schedule. In fact, all three engine models were certified within one year.

|

| Gael Meheust, president and CEO of CFM International |

“The LEAP development programme has been absolutely unprecedented,” Meheust continued. “Over the course of five years, we were developing three engines simultaneously and the team did a phenomenal job keeping it all on schedule. In fact, we actually ran the first full LEAP engine in 2013, two days ahead of the target date we had set back in 2008.

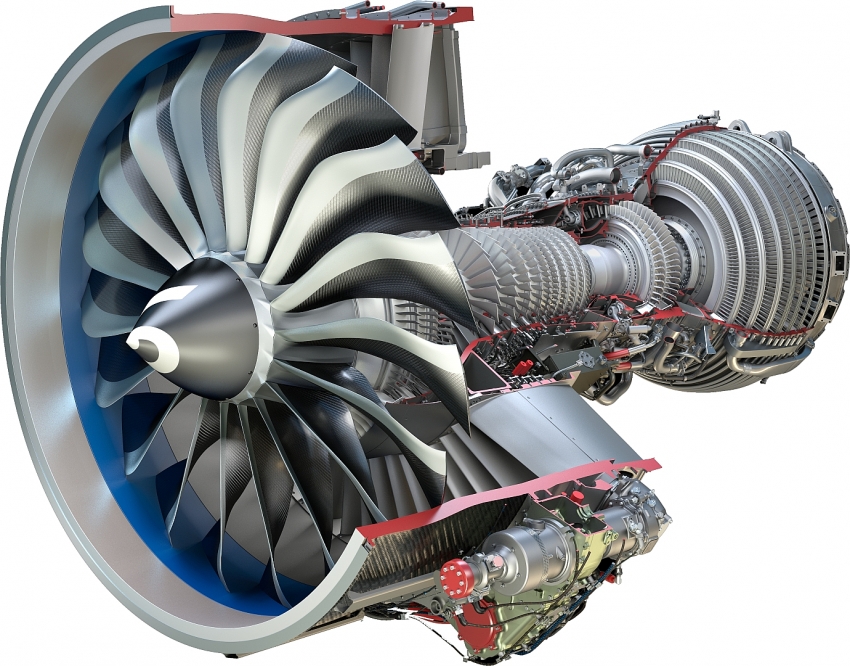

Incorporating advanced, light-weight materials into its the LEAP engine, CFM is leading a new technology revolution. The foundation of CFM's advanced LEAP engine is heavily rooted in fourth-generation aerodynamic design and environmental technology, but it is the advanced materials the company is introducing in this engine – most of them industry fists - that are changing the way aviation looks at jet propulsion and laying a solid technology pathway for the future engine developments.

CFM’s long-term technology investment strategy has been paying off in a big way for its customers.

On August 2, 2016 Turkey’s Pegasus Airlines became the first airline to operate CFM’s advanced LEAP-1A engine on an Airbus A320neo. On May 22, 2017, Malaysia’s Malindo Air operated the first LEAP-1B-powered Boeing 737 MAX commercial flight.

Through November 2018, LEAP engines had powered more than 1.5 million flights and flew more than 2.6 hours for more than 80 operators worldwide. The engine has also shown exceptional reliability, with LEAP customers operating the engine up to 11 flights a day, with many of them executing 25-minute gate turn times.

At the same time, the engine is delivering on the promised 15 per cent improvement in fuel consumption and CO2 emissions compared to today’s best CFM engine, along with dramatic reductions in engine noise and exhaust gaseous emissions.

|

| LEAP Engine |

All this technology is focused on providing better utilisation, including CFM’s legendary reliability out of the box, greater asset availability; enhanced time on wing margins to help keep maintenance costs low, and minimised maintenance actions, all supported by sophisticated analytics that enable CFM to provide tailored, predictive maintenance over the life of the product.

“At the end of the day, we have designed an engine that has met every one of our commitments and we are incredibly proud of this accomplishment. But even more important than that, our customers love this engine; that is the true measure of our success,” said Meheust.

LEAP engines are a product of CFM International, a 50/50 joint venture company between GE and Safran Aircraft Engines and the world's leading supplier of commercial aircraft engines.

CFM International (CFM) was formed in 1974 as a 50/50 joint company between GE and Safran Aircraft Engines. Today, CFM is the world’s leading supplier of commercial transport aircraft engines and the best example of a successful international joint venture.

Since the first engine was delivered in 1982, CFM has received orders for more than 50,000 CFM56 and LEAP engines from 590+ operators worldwide, of which more than 33,000 engines have been delivered.

The agreement that established CFM calls for the two parent companies to share everything equally, from design and development to production and support. Final engine assembly is performed both at GE facilities in the U.S. and Safran.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Addressing Vietnam's energy challenges with aeroderivative gas turbines (February 28, 2023 | 09:33)

- How to sprint ahead in 2023’s worldwide energy priorities (February 08, 2023 | 13:55)

- Boosting Vietnam's grid stability through gas turbine technology (November 22, 2022 | 20:02)

- Healthcare trio collaborates to provide thousands of free breast scans (October 27, 2022 | 17:19)

- GE Healthcare's vision for AI-backed radiology (September 29, 2022 | 11:53)

- GE brand trio to shape the future of key industries (July 19, 2022 | 15:35)

- GE unveiling brand names and defining future (July 19, 2022 | 15:16)

- GE: the shortest route towards sustainability (July 18, 2022 | 08:00)

- Be proactive in an uncertain world (May 20, 2022 | 11:40)

- GE secures first 9HA combined cycle power plant order in Vietnam (May 16, 2022 | 17:06)

Tag:

Tag:

Mobile Version

Mobile Version