Positivity and cooperation can boost nation’s innovation

|

On June 3, 2018, just three days before the completion ceremony of the first VinFast car, Vo Quang Hue test drove the Lux SA 2.0 car to try it for himself. He was the deputy CEO of Vingroup in charge of the VinFast project.

Although he had completed test driving courses on BMW’s test track in Germany and had significant test driving experience under his belt, Hue still could not help but feel excited.

“I had read reports from Magna Steyr and AVL, leading automotive engineering companies who partnered with VinFast at the time. They saw excellent results when testing the cars with various methods, including in different weather conditions and temperatures. However, I still wanted to personally test drive it myself.” Hue reminisced.

This was his second time test driving a car in Vietnam. At the end of 1994, on the newly opened road from Hanoi to Hoa Binh, he drove the first BMW 520i assembled in Vietnam with great enthusiasm.

Hue was born in the south, then studied and lived abroad before returning to Vietnam in 1994 to oversee a project for BMW at Vietnam Motors Corporation. At a time when Hanoi still lacked streetlights, and Noi Bai Airport had only one runway, BMW had modest plans to sell 300 cars a year in Vietnam. Back then they struggled to achieve even half of their target.

Fast forward to his second test drive in Vietnam for VinFast in 2018, tens of thousands of customers had already registered to buy their cars. These registrations started coming in even before VinFast had constructed the factories, began engineering activities and hired staff. With the growing middle class, Vietnam had become one of the most attractive consumer car markets in ASEAN.

To realise his childhood dream of manufacturing cars in Vietnam, Hue started studying automotive engineering in Germany in 1970. After successful careers at BMW and Bosch, he was invited to join Vingroup and participate in founding VinFast, a car manufacturing company bearing the Vietnamese brand.

Maintaining quality

Initial skepticism spread during the debate about how VinFast could produce and release a new car model in just two years. “How could they do it when Vietnam couldn’t even produce a screw?” Hue remembered many people saying.

“They didn’t understand that the global automotive supply chain had been established for a long time, so the notion of having to produce everything in-house was outdated.”

According to Hue, instead of producing all components themselves, modern car companies worldwide focus on core capabilities like unique vehicle designs, integrating new technologies, cost-saving, and branding.

He explained that companies like BMW conduct global research and seek new solutions to significantly reduce in-house manufacturing breadth, continuously outsourcing component production and pre-assembly to partners at reasonable prices while maintaining quality.

However, he admitted that VinFast’s development process of 22 months was miraculous even for insiders. Everything was set up in this short span of time, including car engineering activities, factory construction, purchasing agreements, shipment and installation of all required machinery and equipment, as well as the recruitment, training, and preparation of thousands of workers for the task.

“The key to our success was the determination of Vingroup’s leaders. I didn’t expect, but gladly welcomed, daily meetings with our chairman, receiving answers from him within minutes of my messages. Such a focused sprint helped the team overcome their limits,” Hue said. The team not only consisted of Vietnamese colleagues but also 180 foreigners who moved away from their families to work at VinFast.

Hue had joined VinFast after 10 years as CEO of Bosch in Vietnam. He recalled that returning to Vietnam to work for Bosch was an opportunity for him to realise his student dream of contributing to Vietnam’s development, which began with his involvement in the student anti-war movement in West Germany.

In 2008, as CEO of Bosch in Vietnam, Hue proudly persuaded Bosch to redirect their investment plans for an automotive components manufacturing plant from China to Vietnam. This led Bosch to set up a full-fledged commercial entity in the country, becoming one of Vietnam’s largest European investors. Their manufacturing, business services, and research and development (R&D) provided thousands of employment opportunities for Vietnamese workers.

About 13 years ago, Hue proposed choosing Ho Chi Minh City as the location for Bosch to invest in software technology, with the initial goal of becoming a branch of the parent company located in Bangalore, India.

Today, Ho Chi Minh City’s eTown is the headquarters of Bosch Global Software Technologies. Over 4,000 people with PhDs, engineers, and foreign experts work there, with about two-thirds of them researching and developing solutions such as autonomous driving systems, providing expertise to car manufacturers in Asia-Pacific and beyond. These are innovative projects which have been managed or implemented directly by Vietnamese engineers. “Bosch’s embedded software system solutions for VinFast cars are in part the products of Vietnamese engineers at eTown.” Hue shared.

|

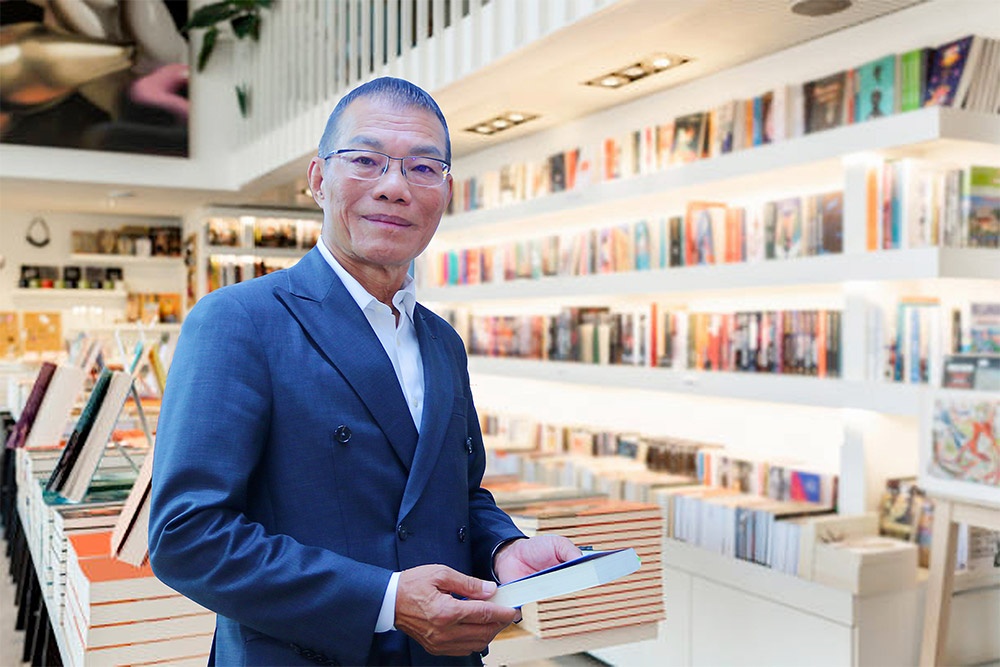

| VinFast has come a long way in just a few short years thanks to people like Vo Quang Hue |

We can do it

Affirming that Bosch’s decision to choose Vietnam as an R&D location was indeed correct, and that their target of employing 6,000 engineers by 2025 seems highly achievable.

Upon co-initiating the Engineering center which later became Bosch Global Software Technologies, Hue and his colleagues aimed to demonstrate Vietnam’s “We can do it” attitude, showing their capability for high quality research and development even in the automotive industry.

While Hue is confident in the abilities of Vietnamese graduates, he is still concerned about creating a suitable working environment in which to train them. Establishing R&D centres like Bosch requires patience and persistence, among other factors.

After 24 years working for BMW in Germany, Southeast Asia, Mexico, and Egypt, followed by his time at Bosch Vietnam and nearly three years at VinFast, Hue has decided to stay in Vietnam to further contribute to his motherland.

Looking back at the long road travelled, including 1,000 challenging days at VinFast, Hue recalls the beginnings, milestones, and journeys throughout his career in the upcoming book titled The Miles I Walked - A Journey from BMW and Bosch to VinFast. It is expected to be published this year.

Following the launch of VinFast’s first vehicle series in 2020, including four gasoline car series and three electric motorcycle series, Hue decided to leave Vingroup. He is now focused on realising his vision for Vietnam to become a global hub for R&D, training, and highly skilled talent in the age of AI.

This vision leads Hue to continue participating in the Vietnam-Germany University Council, and advising vocational training projects for the German Chamber of Commerce in Vietnam and the German Development Agency. He also shares his knowledge and experience in investments, corporate capacity building, and international collaboration with Vietnamese enterprises, especially technology startups, which now is the focus of his work.

“I hope that more large and medium-sized Vietnamese companies will have an R&D department to collaborate with universities and research institutes, to become sources of innovation for new manufacturing, product, and technological development.” he said.

“This would be a solid foundation for Vietnam’s competitiveness with developed countries.”

| Investment opportunities for automotive component manufacturers The leading 25 automotive component manufacturers from India arrive in Vietnam from August 21 to 26 to look for investment opportunities. |

| Automotive giant to lead the push for electric taxis in Vietnam The participation of giants is leading the push for electric taxis in Vietnam which would reshape the taxi landscape towards more green transportation but the fares remain a decisive factor. |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- PM outlines new tasks for healthcare sector (February 25, 2026 | 16:00)

- Ho Chi Minh City launches plan for innovation and digital transformation (February 25, 2026 | 09:00)

- Vietnam sets ambitious dairy growth targets (February 24, 2026 | 18:00)

- Masan Consumer names new deputy CEO to drive foods and beverages growth (February 23, 2026 | 20:52)

- Myriad risks ahead, but ones Vietnam can confront (February 20, 2026 | 15:02)

- Vietnam making the leap into AI and semiconductors (February 20, 2026 | 09:37)

- Funding must be activated for semiconductor success (February 20, 2026 | 09:20)

- Resilience as new benchmark for smarter infrastructure (February 19, 2026 | 20:35)

- A golden time to shine within ASEAN (February 19, 2026 | 20:22)

- Vietnam’s pivotal year for advancing sustainability (February 19, 2026 | 08:44)

Tag:

Tag:

Mobile Version

Mobile Version