Nestlé Vietnam accelerates digital transformation to achieve sustainable development

|

| Nestlé Vietnam is known for popular products like Milo |

Nestlé Vietnam's sustainable growth is based on three pillars, including digital transformation, innovation – in which the consumer is the focus – and sustainable development. In particular, digital transformation is defined as the process that covers the entire operation of the company. It helps create the foundation for growth, promotes flexibility, and creates efficiency in the management and operation process. Thus, the digital transformation can contribute to the sustainable development of the company and the community.

Speaking at today's webinar titled Digital Transformation to Breakthrough: Technology Solutions or Strategic Thinking of Enterprises, Urs Kloeti, director of Nestlé Bong Sen Factory, shared the successful usage of digital applications in operation and production to help Nestlé create breakthroughs.

Kloeti said, "Nestlé gives a priority to the digitalisation of data, thereby finding and applying the right technologies. The most important thing in the strategy at Bong Sen factory is to equip and develop the necessary skills for the staff to access and master technology."

He added that Nestlé Vietnam's digital transformation is built upon five important foundations: Strategic orientation, centralised governance, infrastructure, highly-qualified human resources, and support alignment.

With the goal of using modern technologies in production and operation, Nestlé Bong Sen has adopted over 40 internal applications to help store data and systematise processes that were previously done manually. This not only cuts half of the paper work but also reduces CO2 emissions. The digitalisation helps the factory to reduce 60 per cent of little value added activities to improve overall operational efficiency.

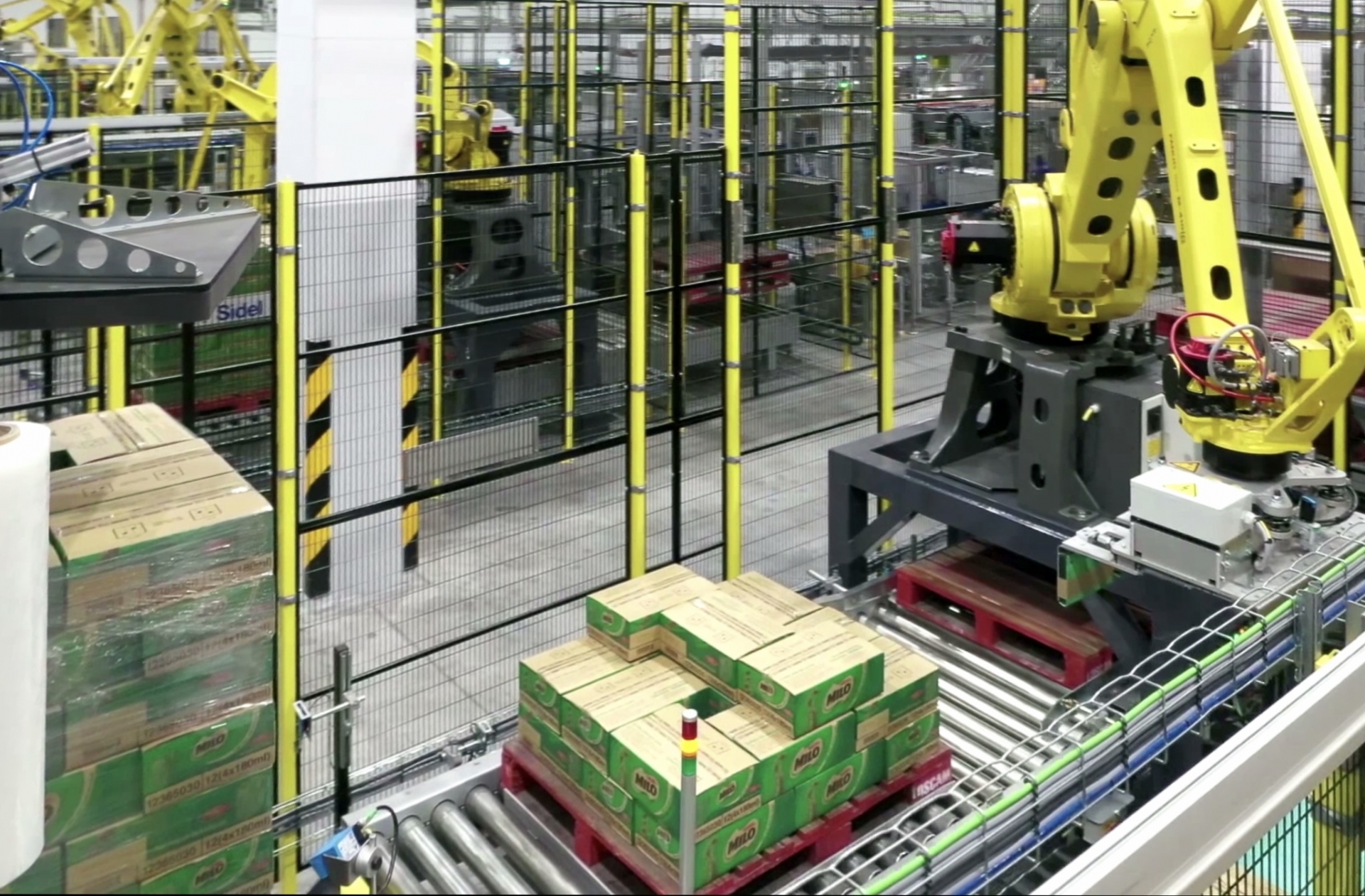

|

| The connected factory model is implemented at Nestlé Bong Sen factory in Hung Yen province |

To implement the model, Nestlé Bong Sen factory not only applies technology in data collection and analysis, but also builds predictive models in production and maintenance activities. As a result, the factory can analyse more than 1,000 processes to identify trends and detect unusual problems in production.

The digitalisation has helped the factory improve productivity and quality significantly, specifically reducing the downtime of the production lines by up to 60 per cent and saving up to 10 million kWh of energy consumption annually.

Talking about the digital transformation, Binu Jacob, managing director of Nestlé Vietnam shared that, "In order to implement the digital transformation successfully, businesses need the right strategy, investment, and priorities in using new technologies such as AI and big data, as well as business analysis tools, to enhance efficiency and profits for them. It is crucial to combine a leadership mindset, a clear technology development roadmap, and workforce capacity building to speed up the transformation of the business. It is also important to select and develop staff capabilities to realise, operate, and maintain businesses effectively. Ultimately, it is about applying the right model and choosing the right technology for the size and development of the business."

Established in 1995, Nestlé Vietnam has continuously expanded and offers diversified products to serve the food and nutrition demand and improve the quality of life in Vietnam. Up to now, Nestlé's total investment in Vietnam has reached $730 million. The company employs 2,200 employees, with four factories in the country.

The company was voted among the Top 3 Sustainable Enterprises in 2020 in the manufacturing sector by the Vietnam Business Council for Sustainable Development under the Vietnam Chamber of Commerce and Industry. Last year, Nestlé Vietnam was lauded by the Ministry of Finance for making significant contributions to Vietnam's state coffers.

|

| Nestlé Vietnam is a pioneer in digital transformation |

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Themes: Digital Transformation

- Dassault Systèmes and Nvidia to build platform powering virtual twins

- Sci-tech sector sees January revenue growth of 23 per cent

- Advanced semiconductor testing and packaging plant to become operational in 2027

- BIM and ISO 19650 seen as key to improving project efficiency

- Viettel starts construction of semiconductor chip production plant

Latest News

More News

- Bac Ai Pumped Storage Hydropower Plant to enter peak construction phase (January 27, 2026 | 08:00)

- ASEAN could scale up sustainable aviation fuel by 2050 (January 24, 2026 | 10:19)

- 64,000 hectares of sea allocated for offshore wind surveys (January 22, 2026 | 20:23)

- EVN secures financing for Quang Trach II LNG power plant (January 17, 2026 | 15:55)

- PC1 teams up with DENZAI on regional wind projects (January 16, 2026 | 21:18)

- Innovation and ESG practices drive green transition in the digital era (January 16, 2026 | 16:51)

- Bac Ai hydropower works stay on track despite holiday period (January 16, 2026 | 16:19)

- Fugro extends MoU with PTSC G&S to support offshore wind growth (January 14, 2026 | 15:59)

- Pacifico Energy starts commercial operations at Sunpro Wind Farm in Mekong Delta (January 12, 2026 | 14:01)

- Honda launches electric two-wheeler, expands charging infrastructure (January 12, 2026 | 14:00)

Mobile Version

Mobile Version