ABB writes the future of agriculture

|

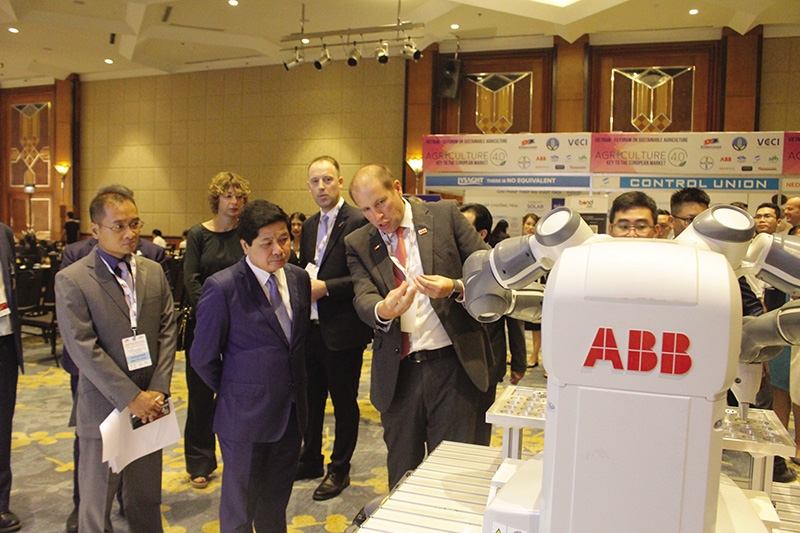

| ABB’s array of robotics solutions will transform how farming is carried out in Vietnam |

According to the Ministry of Industry and Trade, the EU-Vietnam Free Trade Agreement (EVFTA) is especially significant for Vietnamese agricultural exporters because in most other FTAs that the country has signed, agricultural and fishery products are always considered sensitive areas where partners are most tentative to open their doors.

With its abundant natural resources and favourable climate, Vietnam is particularly well suited for agriculture. Accordingly, the agriculture, forestry, and fisheries sectors provided employment to nearly 38 per cent of the working population in 2018. In the first eight months of this year, Vietnam’s agro-forestry-fisheries exports earned $26.6 billion. The country is currently the second-biggest trade partner of the EU in the ASEAN.

Apart from increasing export turnover, the EVFTA will attract more foreign investment, especially from Europe, into Vietnam’s agriculture, thus increasing the value of Vietnamese farm produce in a sustainable way.

“Our world is undergoing transformational technological change. The Fourth Industrial Revolution is profoundly influencing the way we power our societies, produce our goods, as well as how we work, live, and move. Vietnam’s agriculture and the food industry are shifting dramatically to respond to the constant pressure to adapt and evolve to meet the growing diversity of consumer demand, especially in highly demanding markets like Europe.

This means increased production, improved hygiene, quality, and variety – all while maintaining a commitment to safety, traceability, and the sustainable use of natural resources,” said Brian Hull, country managing director of ABB in Vietnam.

He said that ABB are committed to a sustainable agri-food future, supporting Vietnamese manufacturers to improve product quality, enhance food safety and the efficient use of assets through its industry-leading digital

solutions.

Brian Hull shared an example from the milk industry for optimising many milk is a complex product to process. To successfully cater for the critical parameters involved in milk processing – such as temperature, concentrations and flow quantities – and ensure top quality and hygiene, a dairy and the associated supply chain will be equipped with the very best control, sensing and instrumentation technology.

This automation technology will also help optimise raw milk use, reduce energy consumption, and ease daily tasks like cleaning.

Applying AI in the industry

In the agricultural industry, the most popular AI applications focus on four main areas. The first is agricultural robots which are being developed and programmed to automatically handle essential agricultural tasks. These tasks can include collecting data, identifying and spraying weeds, irrigation, picking and packing and more.

Robot control technology uses rapidly-growing AI to help improve efficiency and address the challenges facing the agricultural industry, including crop productivity, soil health, and herbicide resistance.

Second, AI applications focus on the monitoring of crops and soil. Technology for monitoring land, the environment, and crops will also become important applications in the future as climate change continues to be studied and evaluated for environmental impact

Third is predictive analysis involving machine-learning models, cloud computing, and the Internet of Things. Remote sensing techniques are being developed to monitor and to predict different environmental impacts to crop yields. The benefits of improving accurate weather forecasts are determining the best time for planting, fertilising, pesticide spraying, irrigation, and crop harvesting to maximise farming profits.

Finally, AI applications focus on precision agriculture, which will help farmers save on the costs of using water, fertilisers, and pesticides. AI apps will improve management in agriculture and detect pests and the nutritional deficiencies of plant crops on fields.

Crop information, soil conditions, pests, and the weather will be digitised and managed with mapped layers that can interact with each other.

Automated AI applications are being developed to help improve crop productivity, which can help farmers know exactly where to place the fertiliser, and where to water and spray, leading to more efficiency and potentially greater results.

“ABB has demonstrated the ability to apply considerable resources and expertise as a major market leader in sustainable agriculture and food production,” said Brian Hull

It is becoming increasingly difficult to find labour for the cultivation of fresh vegetables, fruit, plants, and crops. Robots can help agricultural and horticultural companies deal with the lack of labour and save on high employee and recruitment costs.

It is a misconception that robots make people superfluous – people will always be necessary for smarter cultivation – but robots can take on a portion of the heavy, repetitive work. If required, robots can be used day and night, which means the greenhouse horticulture sector can cultivate more intensively and with more variety.

In the early 1970s, ASEA (the “A” in ABB) marketed its first industrial robot. Decades of development and experience have resulted in these robots becoming robust and affordable.

When combined with the right vision technologies and tools, industrial robots can also be used as reliable labour in the greenhouse horticulture sector. This relates to things like sowing, maintenance, harvesting, packaging, and palletising plants, fruit, and crops. Thanks to the development of vision technologies, it is possible to harvest fresh products at the right time and potentially package them immediately.

This way, an investment in robotics and horticultural mechanisation is quickly earned back and growers get much more value from their fresh products.

Energy and water savings

It is clear that a greenhouse will require electrification to a large extent in order to be able to achieve sustainable fresh food production which is not reliant on natural gas or other fossil fuels and is close to urban areas.

The sustainability of electricity is dependent upon the method of generation, storage, and transportation, as well as consumers using energy as efficiently as possible through automation and the utilisation of efficient capital assets.

ABB has all the ingredients necessary to help create a fully electric greenhouse, together with the grower and the system integrator. This can range from the sustainable generation of electricity via solar power or wind energy, with or without the storage of that energy, to traditional grid connections to transformers and energy distribution.

The climate inside the greenhouse significantly affects the quality of the harvest. ABB supplies medium-voltage and low-voltage frequency transformers for geothermal installations and heat grids, while the inside of the greenhouse can be kitted out with energy-efficient frequency transformers and efficient, quiet electric motors applied to the pumps and ventilators that ensure the climate within the greenhouse is optimal.

Water usage in an enclosed cultivation system, like in a greenhouse, is 10 times lower than for open fields. In large parts of the world clean, fresh water is scarce. ABB’s technology makes it possible for system integrators to treat the water and safeguard the quality so that it can be reused in a circular system for irrigation and the supply of nutrients.

A wide range of solutions

Not all fresh products need sunlight to grow, but they do need a light spectrum. Modern greenhouse horticulture is using lighting systems with increasing frequency to influence the growth and properties of fresh products and increase yield.

These lighting systems can also be used for vertical farms or cultivation systems in buildings that do not get any natural light.

These vertical farms make it possible to get fresh products, which contain a lot of air or water, to consumers’ plates as fresh and full of flavour as possible, especially in urbanised areas. ABB provides solutions to link up, secure, and monitor these kinds of lighting systems in a sustainable way.

Big data, IoT, and blockchain in agriculture

Big data plays an important role in creating innovations, including in agriculture and horticulture. These installations are linked to each other via modern communication facilities and can communicate with each other and/or with a cloud-based server.

The digital solutions from the ABB Ability™ programme provide the keys, based upon the collected data, to the continuous optimisation of installations and energy flows. Farmers and growers are thus free to focus entirely on their core activities, while the analysis of the data makes it possible for them to make well-considered decisions.

As consumers and as a society, we are making increasingly higher demands on the quality of our food and the way in which it is produced, preserved, and distributed. With the aid of track-and-trace solutions, we are able to guarantee the quality of fresh products.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Tag:

Tag:

Themes: EVFTA & EVIPA

Related Contents

Latest News

More News

- EVN awards EPC contract for Quang Trach II LNG project (February 10, 2026 | 09:00)

- Canada backs Vietnam’s green transition with AGILE project (February 09, 2026 | 17:41)

- Momentum is real in the race to net-zero emissions (February 02, 2026 | 08:55)

- $100 million initiative launched to protect forests and boost rural incomes (January 30, 2026 | 15:18)

- Trung Nam-Sideros River consortium wins bid for LNG venture (January 30, 2026 | 11:16)

- Vietnam moves towards market-based fuel management with E10 rollout (January 30, 2026 | 11:10)

- Envision Energy, REE Group partner on 128MW wind projects (January 30, 2026 | 10:58)

- Vingroup consults on carbon credits for electric vehicle charging network (January 28, 2026 | 11:04)

- Bac Ai Pumped Storage Hydropower Plant to enter peak construction phase (January 27, 2026 | 08:00)

- ASEAN could scale up sustainable aviation fuel by 2050 (January 24, 2026 | 10:19)

Mobile Version

Mobile Version