Vietnam's dynamic industrial future

|

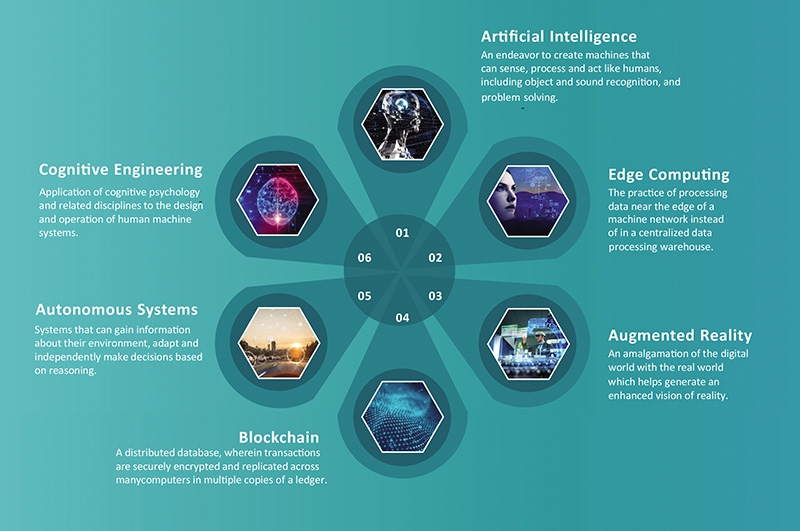

| A factory automation vision for manufacturing processes is built upon the ‘six levers of change’ |

Just for a minute, imagine what a futuristic Vietnam looks like to you. What do you see? Clean energy, flying cars, avatar robots? While this still may be some time away, great ground is being broken to develop the digitalisation technologies and processes that are making previously sci-fi ideas a reality.

|

| Tindaro Danze, head of digital industries and vice president of Siemens Vietnam |

The Internet of Things has already brought so many of our previous fantasies into reality. Consider the smartphone – with apps that have revolutionised the way our daily life functions, from personal trainers on demand and social media, to convenient banking and virtual shopping tours. This vast social, economic, and work-style change is now infiltrating the industrial sector worldwide. This process of digitalising industrial technologies and processes is widely known as Industry 4.0.

Industry 4.0 is able to change our industrial processes from being lengthy, complicated, and expensive to near-immediate, simple, and cost-effective, and it is all centred on value creation and the customer experience. Classic business-to-business transactions converge with business-to-consumer transactions.

This shift is being driven by the Generation Z customer, typically defined as someone born after the mid-1990s. They expect a customised experience and a sense of individualism in their purchasing choices. This generation has grown up with the concept of a 3D printer ready to create any idea into reality. Manufacturers need to evolve with their customers becoming more agile and innovative.

All manufacturing industries are under great pressure to excel in the several key performance indicators. These include speed (the time to market), flexibility (producing customised products), quality (to compete in a globalised market), and efficiency (creating more output for the same input). In order to excel in these key areas, Siemens sees the future of automation revolving around six major levers:

- AI is the lynchpin of the future of automation vision. Its application in the automation space will convert passive assets into self-learning objects that can continuously improve and enable automated process optimisation;

- Edge computing that involves a decentralised computing approach provides value by distributing intelligence/insight generation across multiple assets, helping manufacturers avoid transferring all the process data into an external cloud for analysis;

- Augmented reality transfers the dashboard from control rooms onto the shop floor, potentially enabling operators and shop floor personnel with real-time process know-how. This is especially critical in the future where we see a shortfall in automation skill sets in many developed markets;

- Blockchain technology, a ledger of transactions that can be shared in a digital network, is expected to help support and enable transactions and traceability within a future network-of-factories model. The network model will be characterised by open hardware designs; secure, co-operative supply chains; and a royalty model for shared designs. Blockchain, from an automation standpoint, will drive more transparency into customer-supplier transactions, thereby improving efficiencies and reducing operating costs;

- Cognitive engineering includes bringing principles of cognitive psychology to the design, development, and operations of engineering systems. Besides that, system engineering which is still largely a manual process can achieve high degrees of innovation and ingenuity using this technology lever, supporting manufacturers in reducing operational costs and improving productivity;

- The field of autonomous systems is a subfield of AI, robotics, and information engineering that can enable sedentary assets with navigation capabilities using real-time information. Autonomous systems will greatly improve productivity on the shop floor.

However, this revolution extends far beyond the industrial sector itself. A recent research report released by Deloitte demonstrates how Industry 4.0 is globally changing workplace attitudes and cultures, social mindsets, educational priorities as well as economic structures.

Perhaps the single greatest change Industry 4.0 brings to Vietnam is the movement from being static to being dynamic in operating their businesses. If we went back in time to visit a factory 10, 20, or even 30 years ago, you may find that little has changed. The factory floor would be buzzing with workers who had clocked-in, attended a daily briefing, and got to work manually executing their specific function for the rest of the day.

Problems with machinery or changes in the factory line due to product changes or product modifications could disrupt the day’s work. This process is slow and it could potentially threaten product quality as it demonstrates a lack of flexibility and ultimately harms efficiency. According to an article released by McKinsey, less than 30 per cent of manufacturing companies are actively rolling out Industry 4.0 technologies at scale. This means that the static model – which does little to achieve an increase in the aforementioned factors of speed, flexibility, quality, and efficiency – is still greatly dominating the manufacturing sector.

Industry 4.0 creates dynamic opportunities that minimise disruptions to the manufacturing process, increasing speed and flexibility while improving quality and efficiency.

Recent research has found that one major factor why manufacturers are not fully embracing an Industry 4.0 model is the fear of the unknown. The Asia-Pacific region stands out particularly in having this concern. Only 8 per cent of executives in the region interviewed in Deloitte’s recent report “The Fourth Industrial Revolution is Here – Are you Ready?” believe that they are equipped with the necessary capabilities to guide their enterprise through this time of change and 20 per cent of the respondents even raised concerns on the potential social upheavals and questions of income inequality which may come along with this transformation.

These results obviously show hesitations in full-heartedly investing in Industry 4.0 transformation programmes. While the fear of the unknown is understandable, digitalisation remains binary – the winner takes it all. Manufacturers who cannot or will not embrace Industry 4.0 will fall behind as they simply will not compete with those who do.

The fear of the unknown will only be overcome with collaboration between governments, the industrial sector, and the educational sector. This co-operation will ensure value creation for society as a whole and each element is not stranded individually, but stronger together.

Government stakeholders pave the way forward by standardising legal frameworks, especially with regards to data management and digital infrastructure. Meanwhile, the industrial sector must prepare their workforce by scaling up digital competence throughout their enterprise, from the shop floor to the top floor. The educational sector, on the other hand, plays a vital role to provide young talent with the necessary toolkits to increase employability in this new age.

Learn-to-learn in this context may be the most important lesson to be incorporated in the 4.0 curriculum, shifting from a content-centred approach towards developing adaptive skills as the centrepiece of education.

Global players such as Siemens are required to set the tone in driving such collaboration. At Siemens Vietnam, this is exactly what we aim to do with our initiatives at various universities and vocational schools throughout Vietnam, while at the same time being a sparring partner for government institutions such as the Ministry of Industry and Trade in discussing the needs for a 4.0 landscape in Vietnam.

One example of Siemens dedication to scaling up competence is our recently launched Digital Academy, SITRAIN, in the heart of Ho Chi Minh City. It is the result of our commitment to creating value for society by offering professional education.

We are well on our way to a future that is only limited by our imagination. Vietnam has a great path ahead and each step towards embracing digitalisation brings us closer to our dreams. The great interest the government has in investing in education and technology, as well as the co-operation it is building with multinational organisations, is creating a framework for Vietnam to own the Fourth Industrial Revolution.

The young people of Vietnam are educated and well-versed in increasingly agile skills and racing ahead into the digital future. So go ahead, take a minute, and keep imagining. The future is closer than you think.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

- Carlsberg Vietnam delivers Lunar New Year support in central region (January 28, 2026 | 17:19)

- TikTok penalised $35,000 in Vietnam for consumer protection violations (January 28, 2026 | 17:15)

Tag:

Tag:

Mobile Version

Mobile Version