VN textile firms need to up ties

|

| Workers of the Nha Be Corporation produce clothes for export. Experts have called for closer co-operation between textile and logistics sectors to improve their competitiveness.-Photo tuoitre.vn |

Nguyen Tuong, Vice Chairman of the Viet Nam Logistics Association, said the textile industry needs to import raw materials from abroad and export products to foreign markets.

Working together, many enterprises could purchase raw materials by combining their orders to create a large shipment, which will help significantly reduce transportation costs, he said.

The costs of logistics currently account for nearly one-third of the costs of each textile product exported, so the Vietnamese garment sector could save more than US$1 billion per year by reducing this cost.

Additionally, Truong Van Cam, Vice Chairman of the Viet Nam Textile and Apparel Association, said most textile companies currently perform outsourcing jobs, causing them to depend on the supply of raw materials and transportation services of providers assigned by their partners.

Most of these providers are foreign companies, thus the market share for local logistics companies has been narrowed, Cam said.

Further, high transportation costs are undermining the competitiveness of Vietnamese goods in international markets, he added.

Director of the Nam Viet Co Ltd, Nguyen Duc Chuong, said that during peak seasons, textile firms have to pay the container imbalance charge (CIC) – a kind of sea freight charge which a carrier requires to offset costs arising from the transfer of a large amount of empty containers from one place to another.

This charge is only affordable to enterprises with large-scale import-export orders, such as Nha Be Corporation or Viet Tien Garment Joint Stock Corporation, but is a heavy burden on small and medium-sized textile firms.

Meanwhile, there is a lack of confidence between the owners of goods and Vietnamese logistics service providers due to low-quality and high prices, said representative of the Dam San joint stock company, which specialises in producing fibers.

Located in the northern province of Thai Binh, the firm has to spend $3 billion to $4 billion every year on logistics costs.

Self-services

To improve the quality of the supply chain and reduce logistics costs, many textile enterprises have turned towards "self-service".

A representative of the Nha Be Corporation said the corporation has established the NBC logistics company to carry and load goods, and to export and import procedures for its shipments.

To facilitate the transaction, NBC logistics firms also opened a representative office in China’s Shanghai, and many textile enterprises are seeking to hire it to perform export and import services.

So far, conducting self-logistics services for approximately 70 per cent of their goods has helped the corporation save $2 billion per year. Previously, it had to pay $6 billion for import-export of goods annually.

However, self-service is still not a solution for small and medium-sized firms.

Therefore, business leaders in the two sectors agreed that it was necessary for the Ministry of Industry and Trade and the Ministry of Transport to assist the coordination and connection between shippers and the owners of goods.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Coteccons honoured with 'VNR Top 50 Vietnam' award for seventh year running (January 09, 2025 | 15:31)

- Vietnam strives for ambitious outcomes (January 08, 2025 | 18:00)

- Labour market equipped to take its next major leap (January 08, 2025 | 16:40)

- Assessing growth drivers in 2025 through expert lenses (January 08, 2025 | 16:35)

- Uber rival Bolt to make foray into Vietnam's ride-hailing market (January 08, 2025 | 15:38)

- Vietnam SuperPort and strategic partners develop rail logistics (January 08, 2025 | 09:37)

- Pharma seeks tech transfer incentives (January 07, 2025 | 16:00)

- AstraZeneca joins efforts for universal health coverage (January 07, 2025 | 14:53)

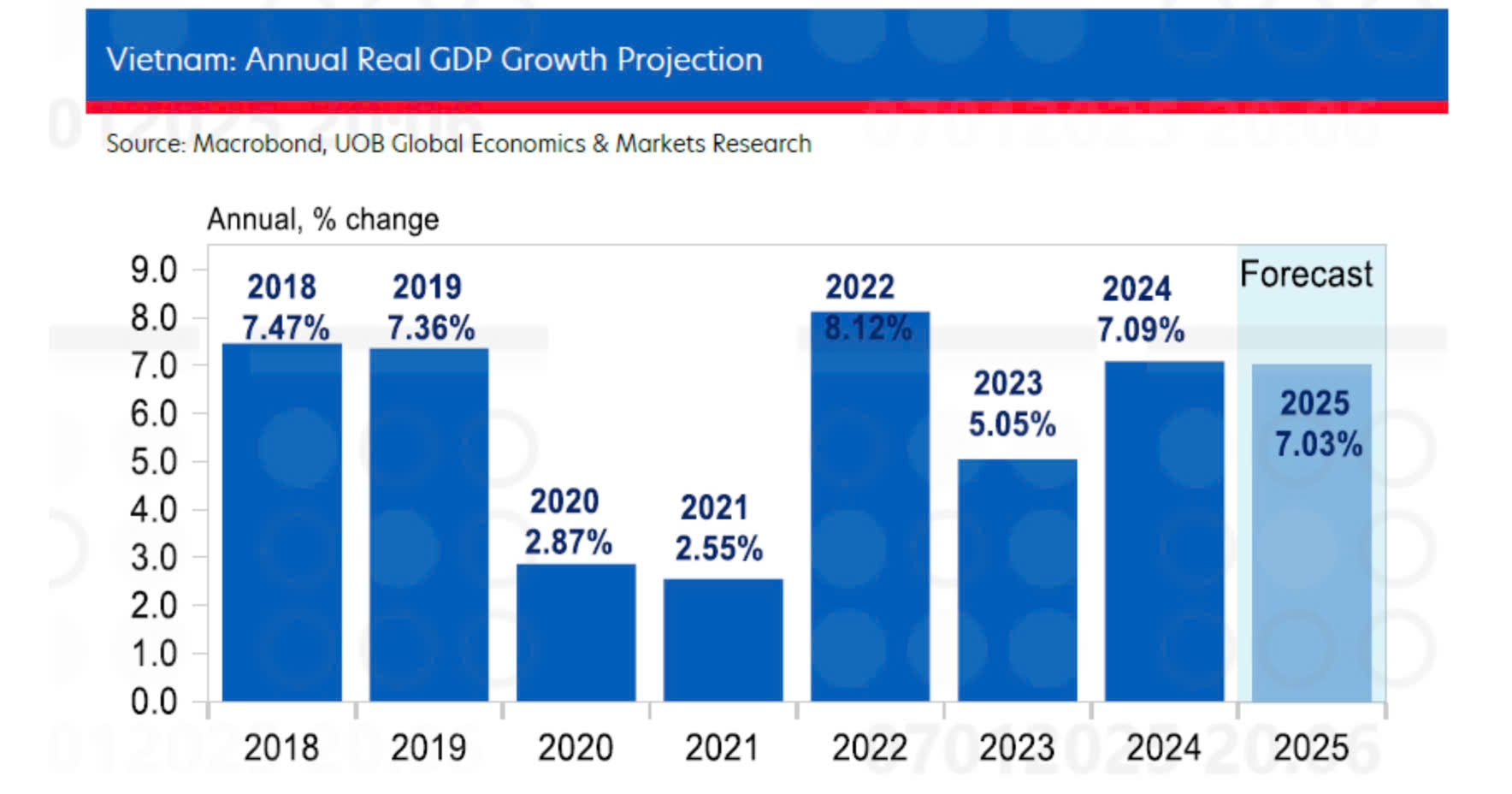

- GDP growth beats forecasts to reach 7.09 per cent in 2024 (January 07, 2025 | 09:25)

- High goals set for import-export (January 05, 2025 | 08:00)

Mobile Version

Mobile Version