SCG’s green pathway towards sustainability

SCG’s interconnected green technologies are ahead of the curve

SCG president and CEO Kan Trakulhoon said that over the past 100 years, SCG had emphasised research and development of innovative, environmentally-friendly products and services.

“This is a key strategy adding to the innovative quality of our products,” said Trakulhoon.

Environmental labeling is used by SCG to communicate its products’ environmental friendliness to consumers and stakeholders. Such products under the SCG and COTTO brands are certified to carry environmental standards from both national and international agencies.

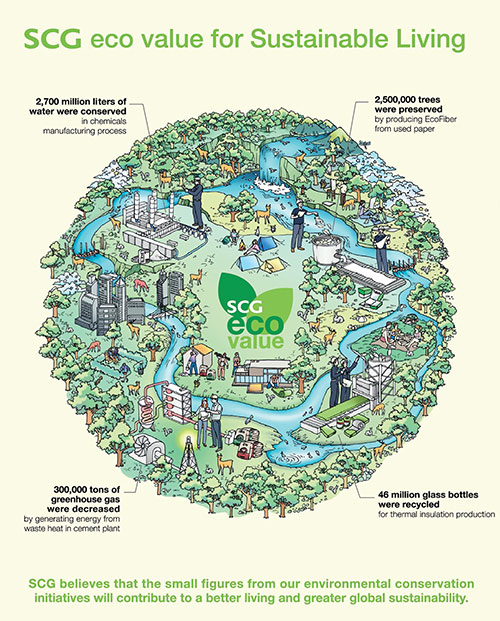

SCG was also the first company in Thailand to distribute products carrying a self-declared environmental label, the “SCG eco value” label that it added in 2009. Last year, 61 SCG products were adorned with eco value labels and their revenues comprised 14 per cent of SCG’s total sales. SCG aims to increase revenue of eco label products to one-third of total sales by 2015. Some of the notable products include Idea Green paper, which uses 30 per cent less tree material and EL Green plastic pellets (used in packaging) which biodegrades under certain temperatures and moisture levels.

Others, such as SCG Marine Cement is seawater resistant and greenhouse gas emissions (GHGs) resulting from its production have been reduced by at least 350 kilogrammes per tonne of cement. Other innovations are COTTO, an anti-bacterial ceramic tile and the SCG service Logistics’ multimodal transportation management system, which cuts down GHGs by 25 per cent against traditional truck transport.

SCG has stipulated that all companies in the group adopt the corporate environmental and resource management policy. This incorporates the 3R: Reduce means to reduce the consumption of materials; Reuse/Recycle means to process old, used items or waste for reuse; and Replenish means to restore or seek alternative resources that minimize environmental impacts. These efforts are designed to enhance the environmental awareness of SCG employees and public in preserving the environment with focus on the 3R.

Trakulhoon noted that toward producing SCG eco value products, SCG was also pushing green production technologies that follow the Reduce, Reuse/Recycle, Replenish principles to use energy and resources in the most efficient way and limit waste and pollutants. SCG is also committed to a “Zero Waste to Landfill” goal, reducing the amount of hazardous waste to landfills to 0 per cent, for all industrial waste produced by its operations.

Moreover, SCG focuses on waste management starting from the sourcing of effective raw materials and those that can be reused in order to minimise the amount of waste that will ultimately need to be disposed. The group has also made an assessment of factors that have affected the environment and systematically record its data and use as base to determine a reduction of natural resources consumption.

SCG is aware of the impact climate change and is aiming for reducing GHGs by 10 per cent of 2007 levels by 2020 and this is, in part, being accomplished by improving machine efficiency and research into alternative fuels.

SCG is taking many other steps to advance its environmental management standards in-line with its sustainable development goals. For example, SCG Cement-Building Materials is installing waste heat power generators and is pushing for different companies within each unit to use the waste of others as raw materials. SCG Paper was the first in Thailand to be certified for its sustainable forest management under Forest Stewardship Council standards.

SCG was also the first organisation in Thailand to establish a Green Procurement policy. This creates a foundation to operate an environmentally friendly business all the way through the value chain. In 2009, 254 products were registered under the Green Procurement list and six new partners joined the programme.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Wages and Lunar New Year bonuses on the rise (February 09, 2026 | 17:47)

- Temporary relief for food imports as businesses urge overhaul of regulations (February 07, 2026 | 09:00)

- Opella and Long Chau join forces to enhance digestive and bone health (February 06, 2026 | 18:00)

- Vietnam-South Africa strategic partnership boosts business links (February 06, 2026 | 13:28)

- Sun PhuQuoc Airways secures AJW Group support for fleet operations (February 06, 2026 | 13:23)

- Pegasus Tech Ventures steps up Vietnam focus (February 05, 2026 | 17:25)

- The generics industry: unlocking new growth drivers (February 04, 2026 | 17:39)

- Vietnam ready to increase purchases of US goods (February 04, 2026 | 15:55)

- Steel industry faces challenges in 2026 (February 03, 2026 | 17:20)

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

![[Infographic] AMATA: Industrial and Smart City Developer](https://vir.com.vn/stores/news_dataimages/2026/022026/12/16/croped/amata-industrial-and-smart-city-developer-20260212165823.jpg?260212050401)

Mobile Version

Mobile Version