GE makes fast company's most innovative companies list

The magazine recognised GE’s chairman and CEO Jeff Immelt for transforming GE into a digital-industrial company connecting machines and businesses to the cloud with Predix, its operating system for the Industrial Internet.

Predix has quickly grown into a $5 billion business with $6 billion in additional orders expected in 2016, the editors noted. “The programme has about 4,000 developers today, and GE is hoping for 20,000 in 2016,” the editors wrote. “And products like Brilliant Factory and Digital Power Plant are designed to drive more efficiencies in factories and power plants by using big data to help save money.”

Take a look at some of the latest breakthroughs from GE below

Digital Twin

Last year GE unveiled the digital twin, a cloud-based simulation of physical assets that allows engineers to optimise machines based on data analytics and predict problems before they happen. There can be digital twins not only of power plants and wind turbines but also of the human body.

Additive Manufacturing

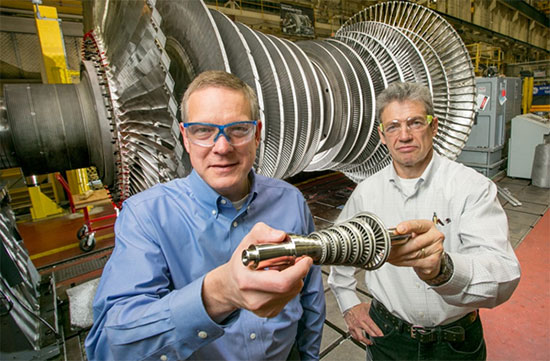

GE engineers shrunk a giant steam turbine

GE is innovating new manufacturing methods like 3D printing that add material to parts rather than cut it away. This allows engineers to create designs they couldn’t manufacture before. GE is using additive manufacturing for everything from ultrasound probes to gas turbines and jet engines including the LEAP, whose order total now stands at $145 billion. GE calls this cross-pollination of technologies across different industries the GE Store. Most recently, GE engineers shrunk a giant steam turbine (see above) and used a 3D-printed mini version of the machine to efficiently desalinate water.

Ceramic Matrix Composites

Scientists at GE Global Research spent the last two decades developing a new kind of ultra-light and super-tough material called ceramic matrix composites (CMCs). It allows jet engines and gas turbines to operate at higher temperatures, making them more efficient. The CMCs were originally developed for the power industry, but like 3D printing, they have applications in other businesses.

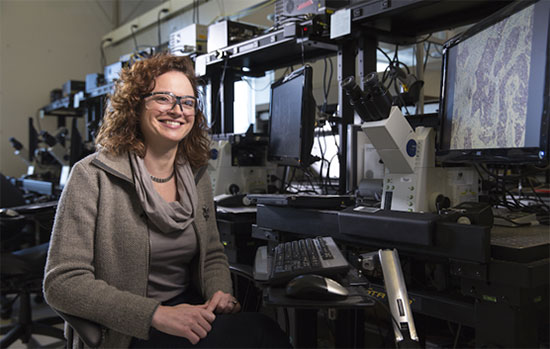

Cancer Research

Scientist Fiona Ginty is leading a team that found a new way to help medical researchers and pharmaceutical companies better understand tumors so they can develop new drugs and therapies. “I liken the process to Google Maps,” Ginty says. “At the 30,000-foot view, you can tell there is a town.

But as you zoom in, you can start to see streets, rivers, stores and other finer details. Our technology gives similar information about tumors, such as how the tumor is organised, where the blood supply is and what the pockets of cells are doing.”

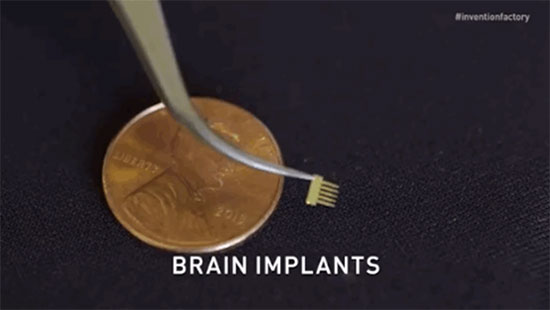

Brain Research

Engineer Jeff Ashe is developing tiny brain implants that could one day improve the lives of people suffering from Alzheimer’s, Parkinson’s or Crohn’s disease. “We’re building tiny machines using semiconductor processing,” Ashe said. “The main one is a MEMS switch. Even though it is so small, it has movable parts inside of it. We can build things that are very small and very strong so they can withstand stress inside the body.”

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Addressing Vietnam's energy challenges with aeroderivative gas turbines (February 28, 2023 | 09:33)

- How to sprint ahead in 2023’s worldwide energy priorities (February 08, 2023 | 13:55)

- Boosting Vietnam's grid stability through gas turbine technology (November 22, 2022 | 20:02)

- Healthcare trio collaborates to provide thousands of free breast scans (October 27, 2022 | 17:19)

- GE Healthcare's vision for AI-backed radiology (September 29, 2022 | 11:53)

- GE brand trio to shape the future of key industries (July 19, 2022 | 15:35)

- GE unveiling brand names and defining future (July 19, 2022 | 15:16)

- GE: the shortest route towards sustainability (July 18, 2022 | 08:00)

- Be proactive in an uncertain world (May 20, 2022 | 11:40)

- GE secures first 9HA combined cycle power plant order in Vietnam (May 16, 2022 | 17:06)

Mobile Version

Mobile Version